3D (3-Dimensional) printing method

A technology of 3D printing and printing models, which is applied in the field of 3D printing, can solve the problems of deformation of forming wall thickness details, etc., and achieve the effect of solving easy deformation, good model quality and appearance, and ensuring printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

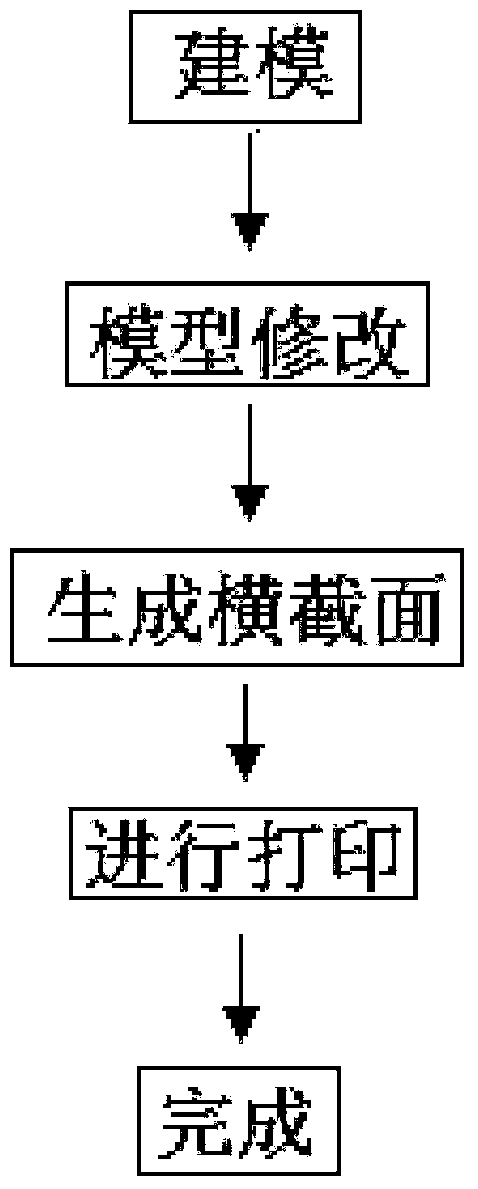

[0040] The present invention provides a kind of 3D printing method, in order to process industrial model to carry out 3D printing through FDM technology and obtain physical model, comprise the following steps:

[0041] Step 1. Modeling: In the computer, the model to be printed is modeled by the 3D model making software, and the CAD model is produced according to the specific data according to the provided drawings;

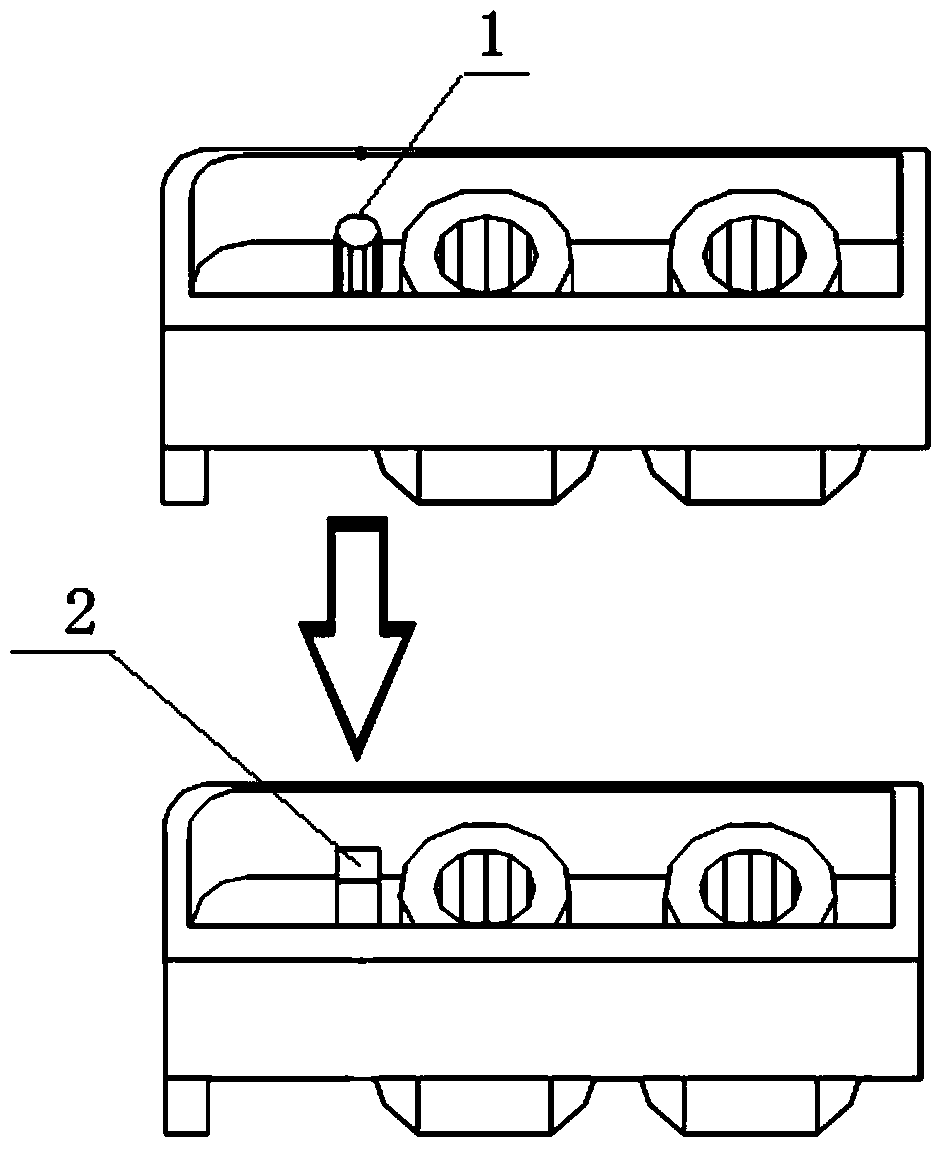

[0042] Step 2. According to the specific size value of the three-dimensional CAD model, modify the cylinder with a bottom surface diameter equal to 0.4 mm in structural size, so that it becomes a rectangular cuboid with a square cross-section whose length and width are 0.4 mm and equal to the height of the cylinder;

[0043] Step 3. Import the generated 3D CAD model into the specific printing data production model software for data slicing processing to generate N cross-sections;

[0044] Step 4. Copy the generated models of N cross-sections to the memory card or ...

Embodiment 2

[0047] The difference from the first embodiment is that the model is a cylindrical structural model of the structural part of the finger. The bottom diameter of the cylinder and the length and width of the cuboid are both 0.6 mm. The other contents are the same as the first embodiment.

Embodiment 3

[0049] The difference from Embodiment 1 is that the model is a circular cross-section pillar model of a railing structure model. The bottom diameter of the cylinder and the length and width of the cuboid are both 0.8 mm. The other contents are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com