Automatic transmission pot body edging system

An automatic transmission and pot body technology, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding workpiece edges, can solve problems such as difficult promotion and application, low degree of automation, and low production efficiency, so as to improve mechanical automation The effect of reducing labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

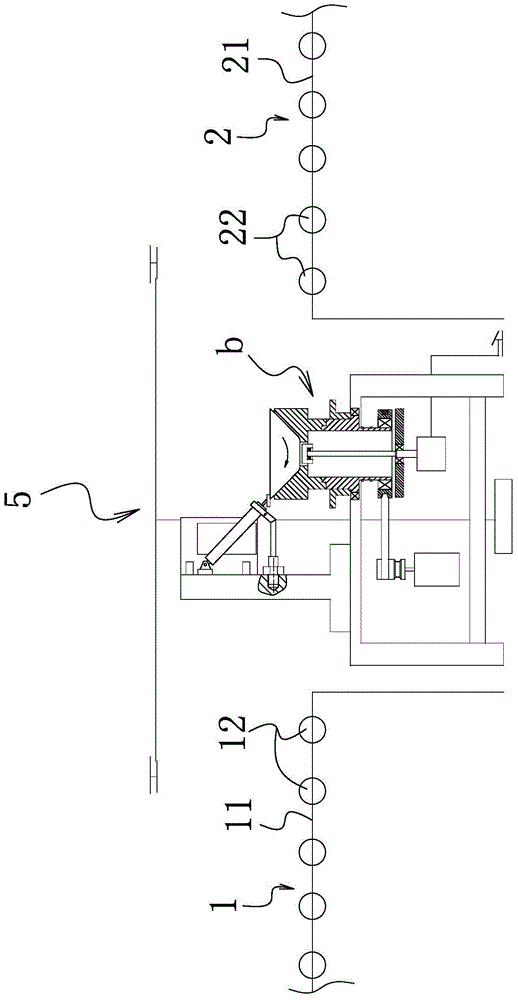

[0024] Such as figure 1 As shown, the automatic transmission type pan body edging system includes a feed mechanism 1 and a discharge mechanism 2, and the feed mechanism 1 includes a feed frame 11, and a number of feed rollers 12 are provided on the feed frame 11; The discharge mechanism 2 includes a discharge frame 21 on which several discharge rollers 22 are arranged. The discharge frame 21 and the discharge roller 22 are sheathed with protective sleeves made of flexible materials. The discharge frame 21 and the discharge roller 22 are connected to the chain respectively, so that they can rotate to drive the pot body to move.

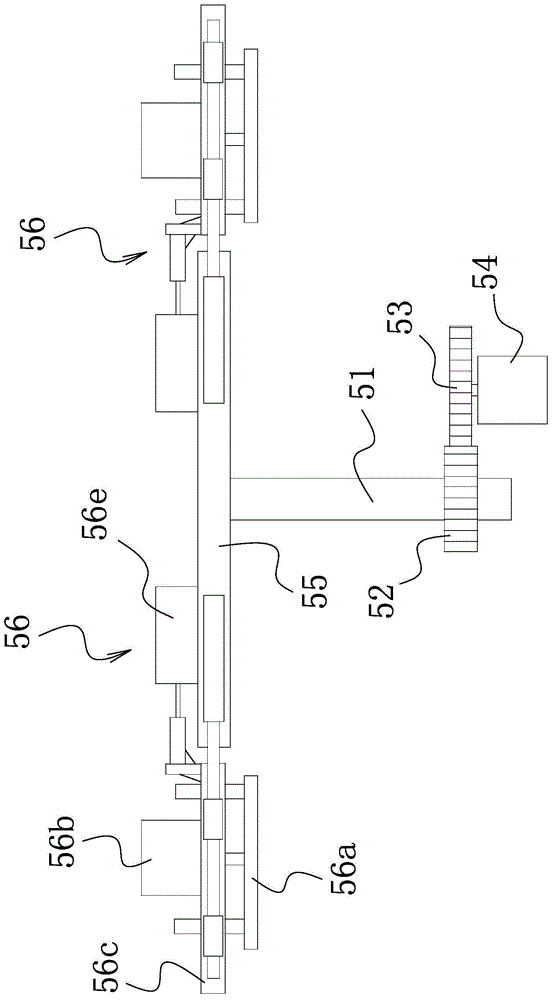

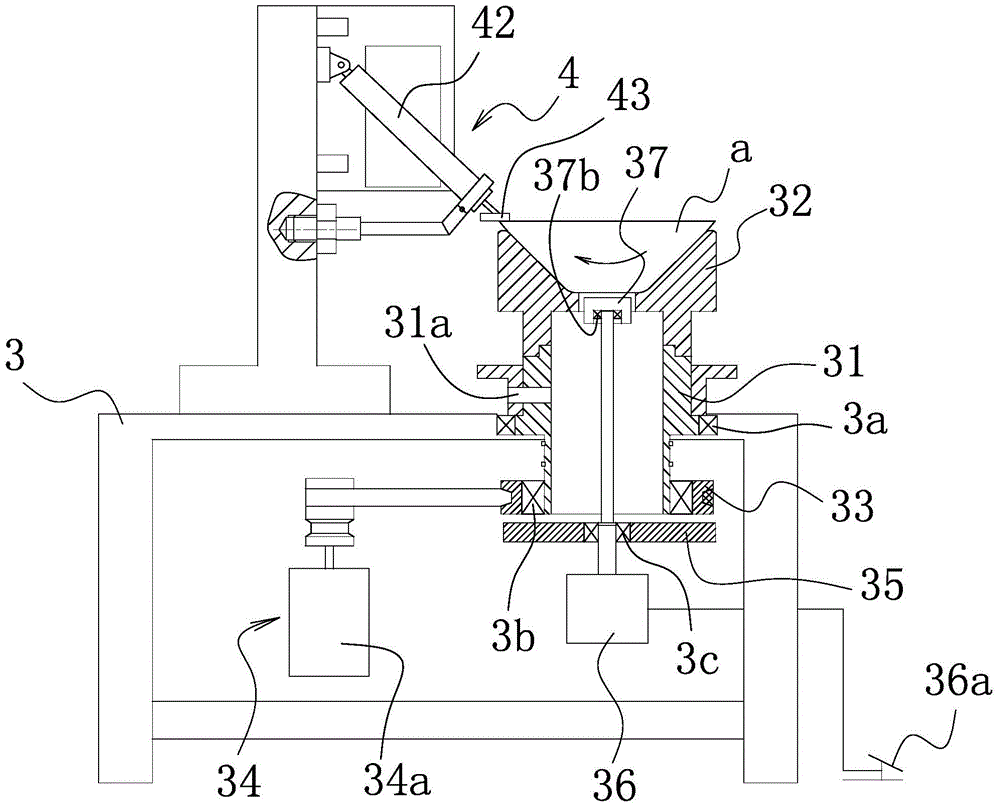

[0025] Such as Figure 1-6 As shown, a pot body edging machine b is provided between the feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com