Photocatalyst lanthanum phosphate and its preparation method and application

A photocatalyst, lanthanum phosphate technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of restricting the practical application of photocatalytic technology, low quantum efficiency, low solar energy utilization rate, etc. It is beneficial to large-scale promotion, the preparation method is simple and feasible, and the synthesis conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the photocatalyst is a hydrothermal method:

[0020] The specific steps are as follows: Dissolve one of sodium phosphate, sodium hydrogen phosphate, ammonium phosphate, and ammonium hydrogen phosphate as a phosphorus source in deionized water to prepare a phosphorus source solution with a concentration of 0.1 to 1 mol / L; it will be used as a lanthanum source One of solid lanthanum chloride, lanthanum nitrate or lanthanum acetate is dissolved in deionized water to prepare a lanthanum source solution with a concentration of 0.01~0.1 mol / L; the phosphorus source solution is added dropwise to the lanthanum source solution while stirring. Then adjust the reaction solution to different pH with dilute ammonia water, continue to stir for 30~180 minutes, transfer it into the autoclave for reaction at 90~240℃ for 12~24 hours, cool to room temperature naturally, wash the precipitate with water and ethanol and centrifuge several times (to Ion concentration <1...

Embodiment 1

[0021] Example 1, LaPO 4 Catalyst preparation

[0022] Weigh 0.003 mol (NH 4 ) 2 HPO 4 The solid was dissolved in 30 mL deionized water to prepare (NH 4 ) 2 HPO 4 Solution; weigh out 0.003 mol La(NO 3 ) 3 ·6H 2 O solid was dissolved in 50 mL of deionized water to prepare a lanthanum nitrate solution, and the prepared (NH 4 ) 2 HPO 4 The solution, then adjust the pH of the solution to 8 with dilute ammonia, continue to stir for 30 minutes, transfer the mixed solution into the autoclave, keep the temperature at 180 ℃ for 24 hours, naturally cool to room temperature, centrifuge the resulting precipitate, wash, 80 ℃ normal pressure Dry for 24 hours and grind to obtain white LaPO 4 powder.

Embodiment 2

[0023] Example 2, LaPO 4 Catalyst preparation

[0024] Weigh 0.001 mol Na 3 PO 4 The solid is dissolved in 30 mL deionized water to prepare Na 3 PO 4 Solution; weigh 0.001 mol La(NO 3 ) 3 ·6H 2 The O solid was dissolved in 50 mL of deionized water to prepare a lanthanum nitrate solution, and the prepared Na was added dropwise to the lanthanum nitrate solution while stirring. 3 PO 4 The solution, then adjust the pH of the solution to 11 with dilute ammonia water, continue to stir for 60 minutes, transfer the mixed solution into the autoclave, keep the temperature at 120 ℃ for 12 hours, naturally cool to room temperature, centrifuge the resulting precipitate, wash, 60 ℃ normal pressure Dry for 12 hours and grind to obtain white LaPO 4 powder.

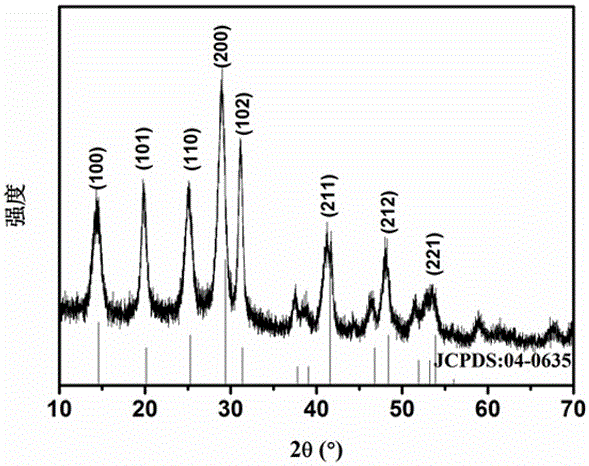

[0025] figure 1 Demonstrated the new photocatalyst LaPO of the present invention 4 X-ray diffraction pattern (XRD), from which you can find the prepared LaPO 4 LaPO with pure hexagonal phase 4 (JCPDS: 04-0635).

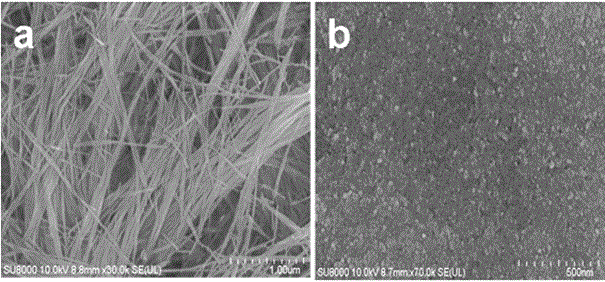

[0026] figure 2 Demonstrated th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com