Preparation method of porous adsorbent for adsorbing heavy metals in marine protein enzymatic hydrolyzate

A technology of proteolysis solution and porous adsorbent, which is applied in the field of preparation of porous adsorbent, to achieve the effect of wide range of raw materials, large adsorption capacity and regeneration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

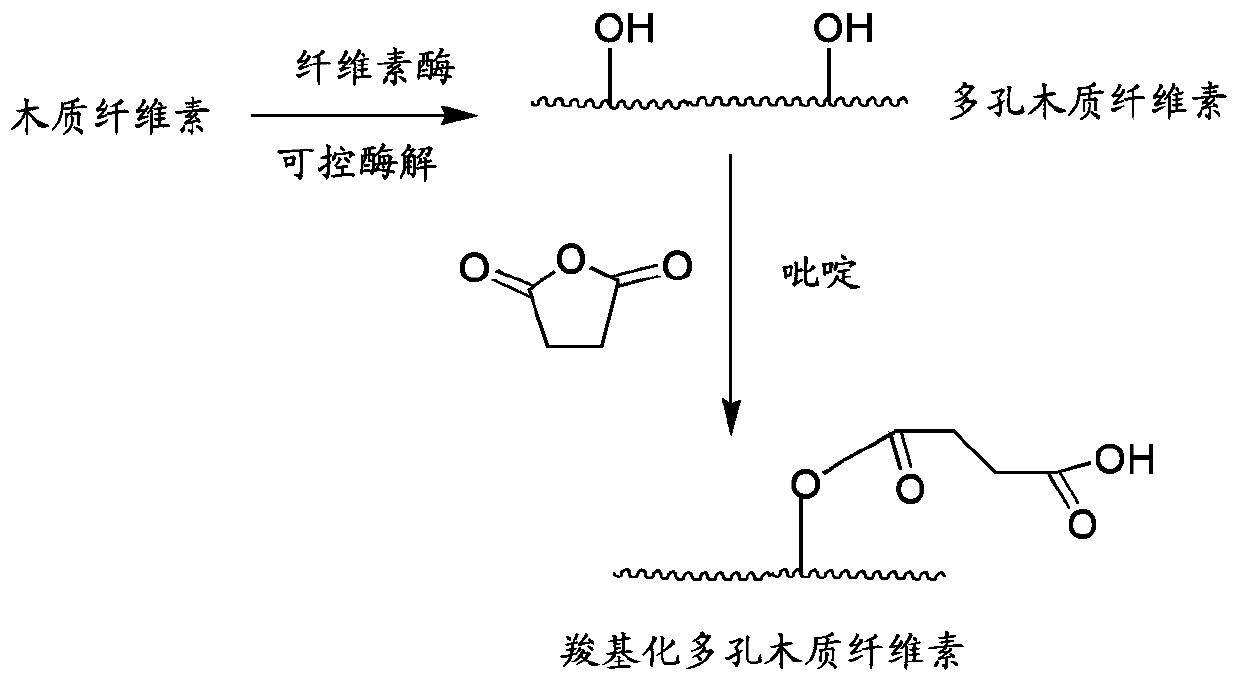

Method used

Image

Examples

Embodiment Construction

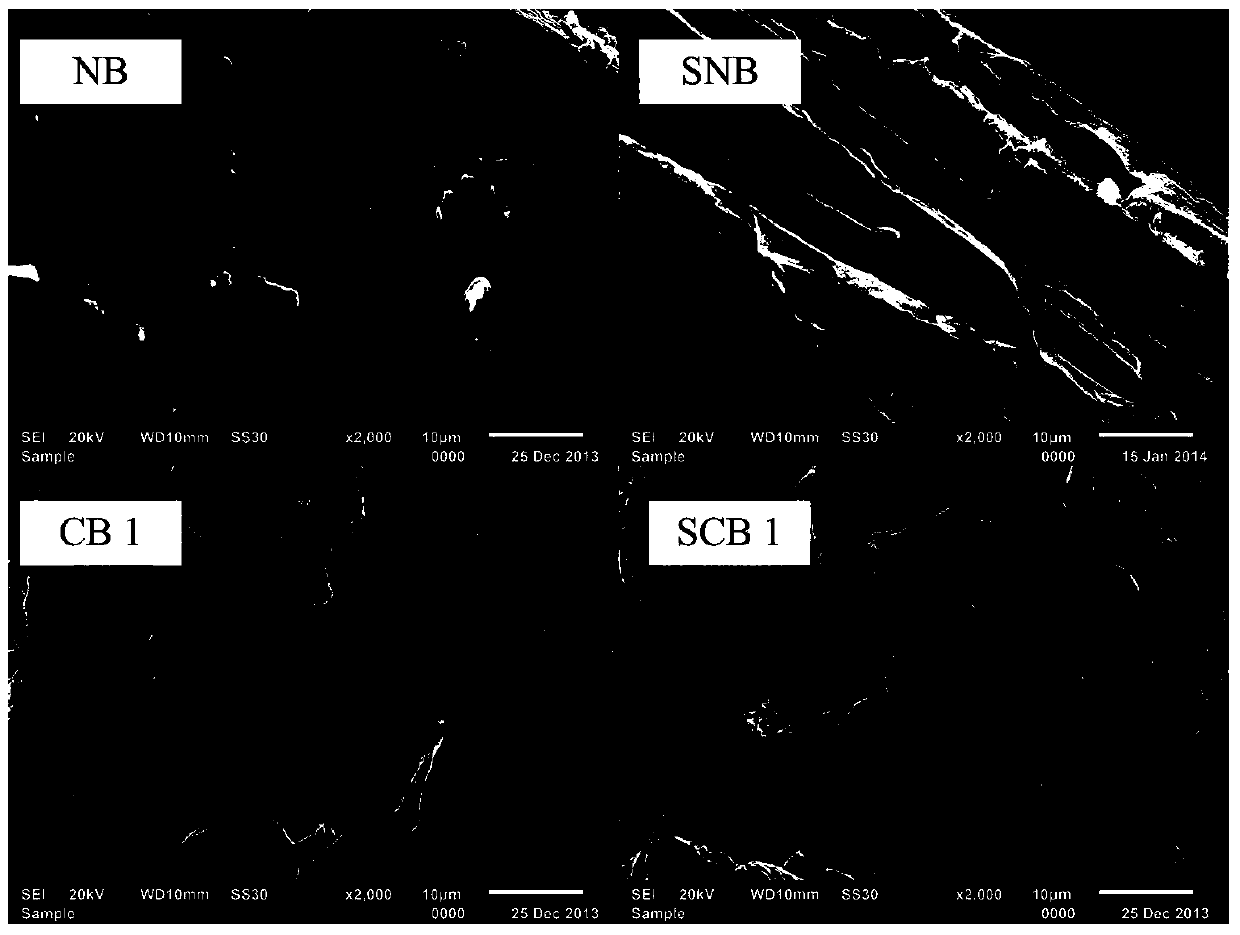

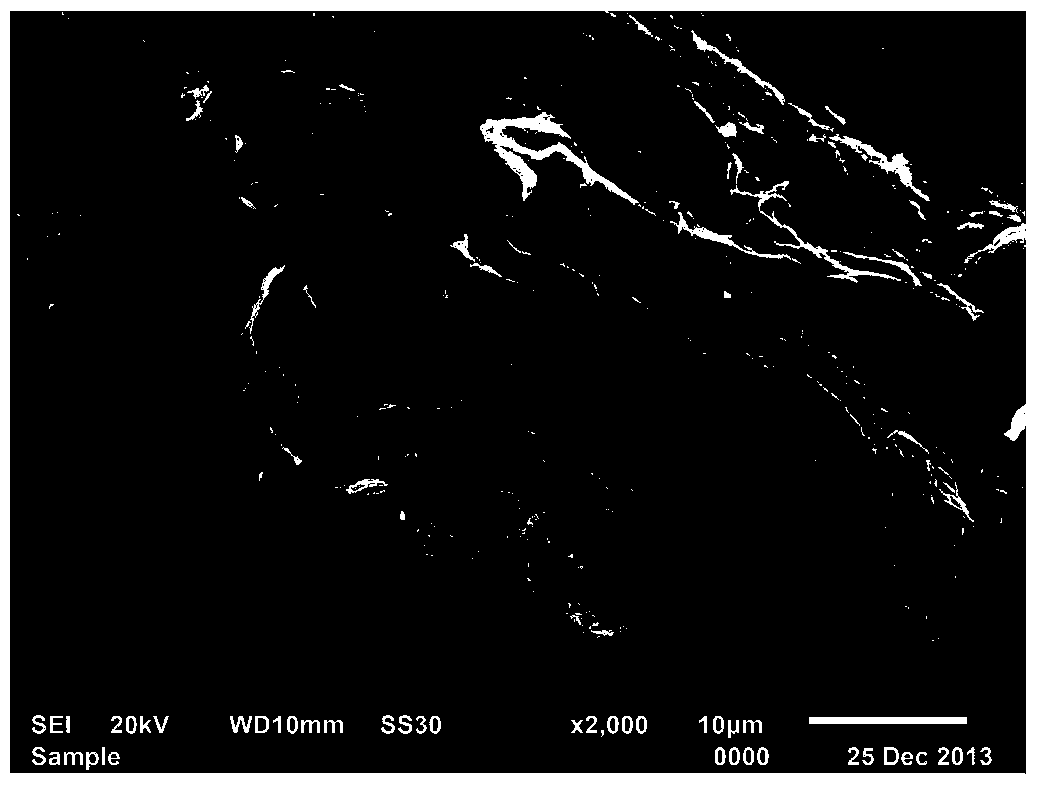

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] The main reagents adopted in the embodiment are shown in table 1:

[0036] Table 1 List of main experimental reagents

[0037]

[0038] The preparation steps are as follows:

[0039] 1. Take bamboo chips as raw material, boil them with distilled water for 1 hour to remove impurities, then place them in an oven, dry them at 80°C for 24 hours, crush them with a pulverizer, pass them through a 100-mesh sieve, wash them with distilled water three times, and dry them at 80°C to obtain the pretreated Bamboo lignocellulose (NB), stored in a desiccator until use.

[0040] 2. Acid-base treatment of bamboo lignin cellulose:

[0041] Bamboo lignocellulose (NB) 40g that pretreatment obtains is mixed with 300mL HCl (1mol / L), suction filtration after ultrasonic treatment 3 hours, ultrasonic treatment adopts 30~50KHz ultrasonic wave, and filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com