Method for sterilizing and disinfecting by utilizing ozone fog

A sterilization, ozone mist technology, applied in the direction of sterilization/microdynamic water/sewage treatment, application, atomized substances, etc., can solve the problems of low ozone solubility, low ozone concentration, poor disinfection effect, etc., to ensure safety, The effect of increasing the generation rate and increasing the ozone concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for sterilizing and disinfecting using ozone mist, the specific process steps are as follows:

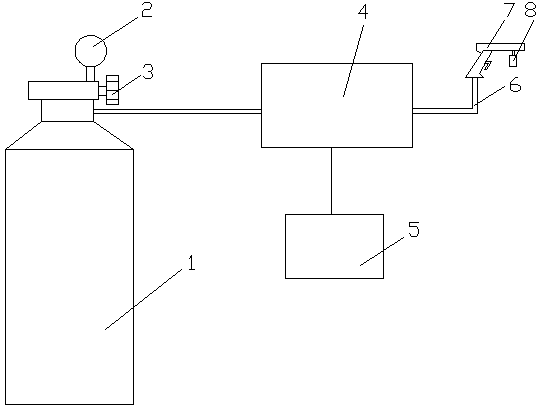

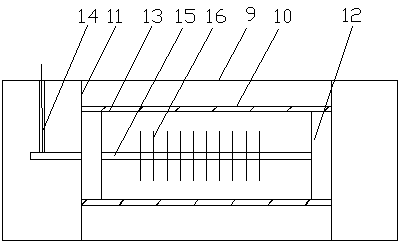

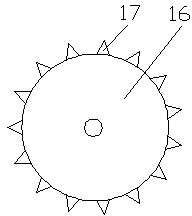

[0047] A. Open the oxygen cylinder 1, pass the oxygen in the oxygen cylinder 1 through the pressure gauge 2 and the pressure regulating valve 3 to adjust the oxygen pressure and then pass it into the ozone generator 4, and turn on the high-voltage power supply 5 at the same time, and the high-voltage electricity generated by the high-voltage power supply 5 is passed into In the ozone generator 4, a corona discharge is formed inside the ozone generator 4 to generate ozone;

[0048] B. The ozone generated in step A is adjusted through the ozone pressure and passed into the high-pressure spray gun 7 through the ozone output pipe 6. The ozone flows in the high-pressure spray gun 7 to form a negative pressure, and the water connected to the kettle 8 under the high-pressure spray gun 7 is sucked into the high-pressure spray gun 7. spray gun 7;

[0049] C. Aim the high-pre...

Embodiment 2

[0052] A method for sterilizing and disinfecting using ozone mist, the specific process steps are as follows:

[0053] A. Open the oxygen cylinder 1, pass the oxygen in the oxygen cylinder 1 through the pressure gauge 2 and the pressure regulating valve 3 to adjust the oxygen pressure and then pass it into the ozone generator 4, and turn on the high-voltage power supply 5 at the same time, and the high-voltage electricity generated by the high-voltage power supply 5 is passed into In the ozone generator 4, a corona discharge is formed inside the ozone generator 4 to generate ozone;

[0054] B. The ozone generated in step A is adjusted through the ozone pressure and passed into the high-pressure spray gun 7 through the ozone output pipe 6. The ozone flows in the high-pressure spray gun 7 to form a negative pressure, and the water connected to the kettle 8 under the high-pressure spray gun 7 is sucked into the high-pressure spray gun 7. spray gun 7;

[0055] C. Aim the high-pre...

Embodiment 3

[0062] A method for sterilizing and disinfecting using ozone mist, the specific process steps are as follows:

[0063] A. Open the oxygen cylinder 1, pass the oxygen in the oxygen cylinder 1 through the pressure gauge 2 and the pressure regulating valve 3 to adjust the oxygen pressure and then pass it into the ozone generator 4, and turn on the high-voltage power supply 5 at the same time, and the high-voltage electricity generated by the high-voltage power supply 5 is passed into In the ozone generator 4, a corona discharge is formed inside the ozone generator 4 to generate ozone;

[0064] B. The ozone generated in step A is adjusted through the ozone pressure and passed into the high-pressure spray gun 7 through the ozone output pipe 6. The ozone flows in the high-pressure spray gun 7 to form a negative pressure, and the water connected to the kettle 8 under the high-pressure spray gun 7 is sucked into the high-pressure spray gun 7. spray gun 7;

[0065] C. Aim the high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com