Self-assembly starch nanoparticle and preparation method thereof

A starch nanometer and self-assembly technology, which can be used in powder transportation, pharmaceutical formulations, cosmetic preparations, etc., can solve a large number of problems, and achieve the effects of simple operation, high spheroidization rate, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of acid-thinned starch

[0036] Weigh 25g (dry basis) of wheat starch and disperse it in 90% ethanol solution to make starch milk with a concentration of 30%, then add 3mL of concentrated hydrochloric acid, react at 55°C for 1.5h, and use Na 2 CO 3 The solution terminated the reaction, adjusted to neutrality, then rapidly cooled to room temperature, washed, centrifuged, and dried.

[0037] 2. Preparation of esterified starch

[0038] Weigh 15g (dry basis) of the above-mentioned acid-thinned starch in pyridine solution to make a solution with a concentration of 10%, activate it at 95°C for 1.5h under stirring, then add 45g of octenyl succinic anhydride, and continue the reaction at 95°C 3h, after the reaction is completed, cool to room temperature, wash, centrifuge, and dry.

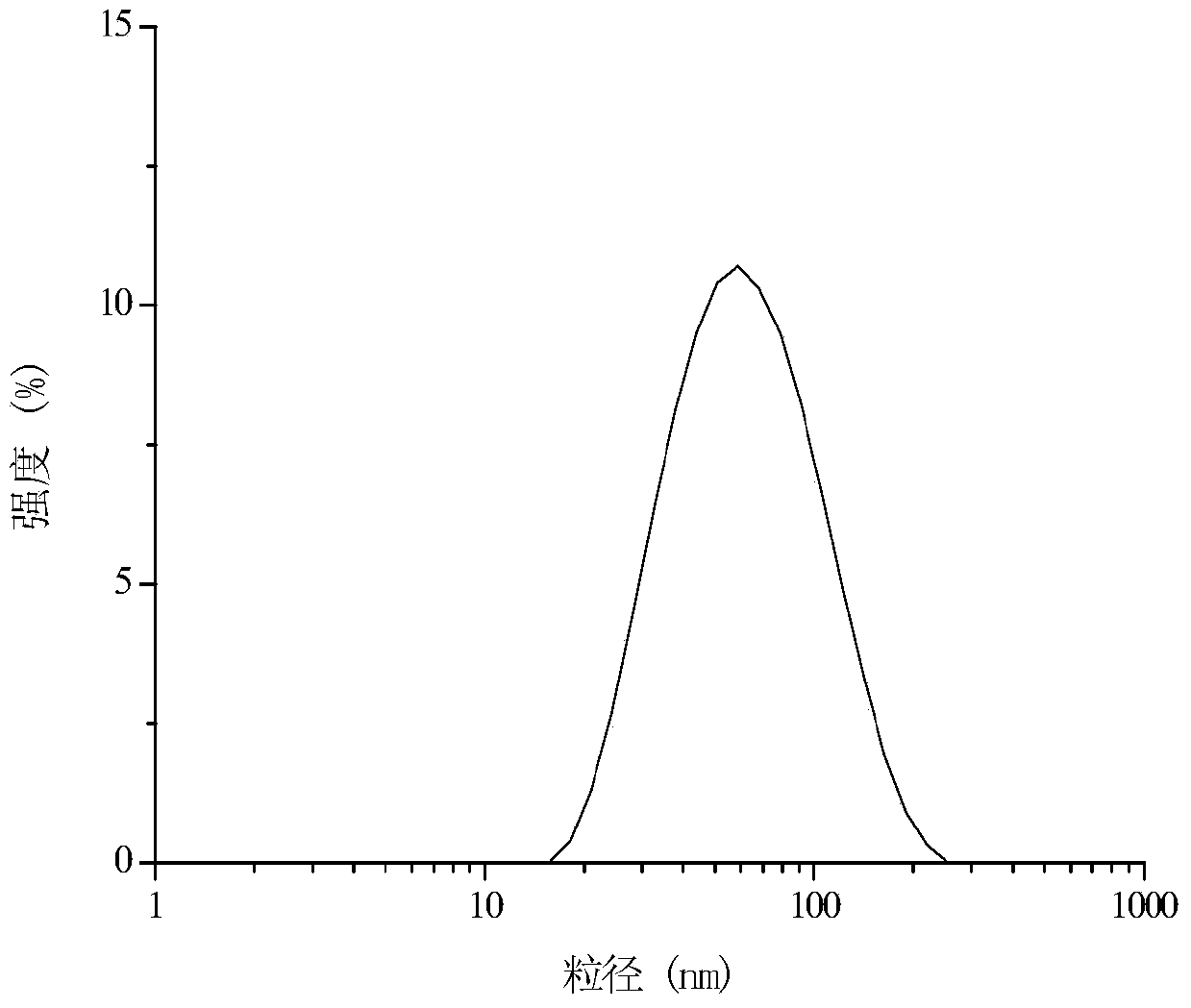

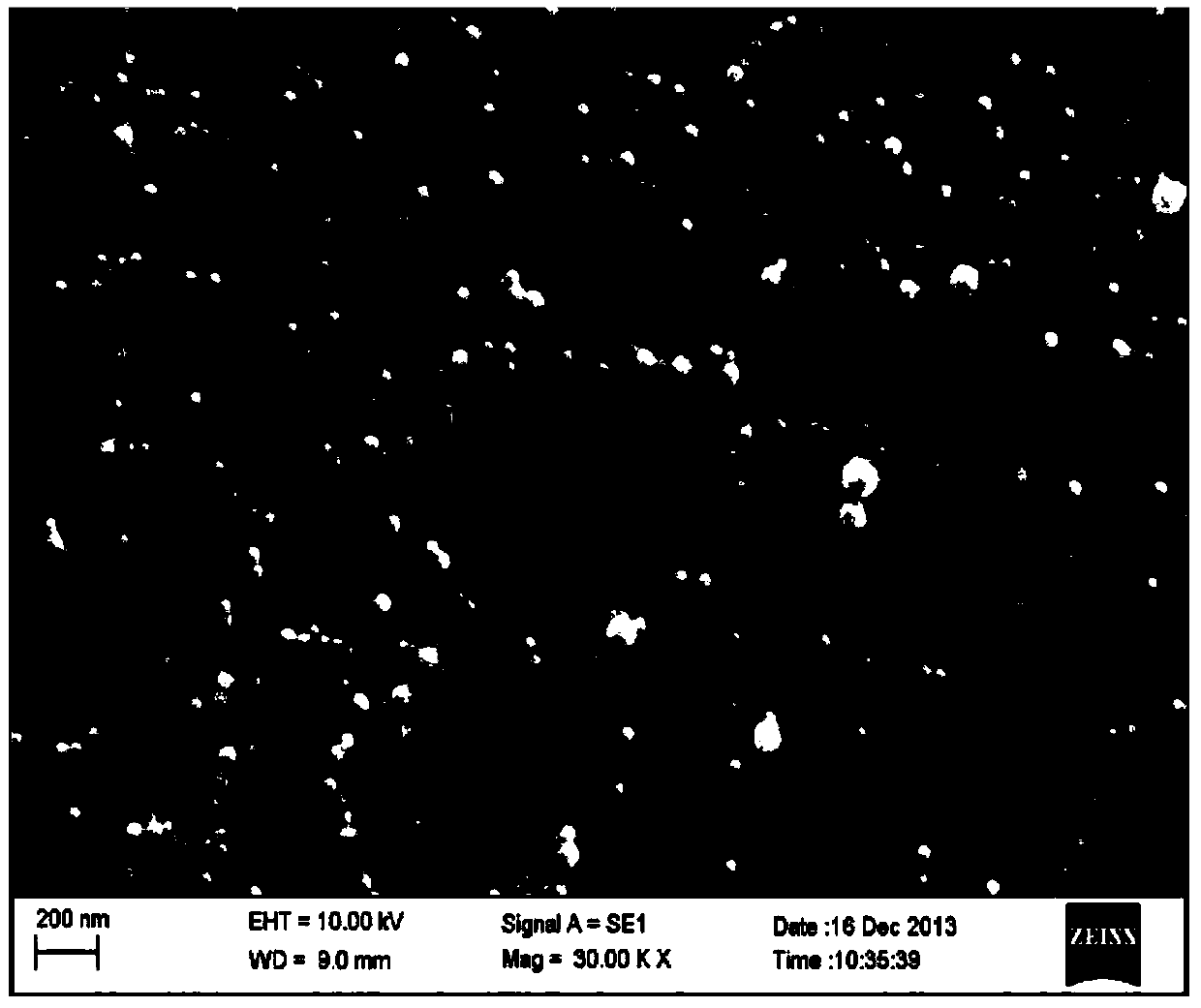

[0039] 3. Preparation of starch nanoparticles

[0040]The inventors found that only starch octenyl succinate with a high degree of substitution can self-assemble into regular and...

Embodiment 2

[0042] 1. Preparation of acid-thinned starch

[0043] Weigh 25g (dry basis) waxy cornstarch and disperse it in 90% ethanol solution to make starch milk with a concentration of 25%, then add 1mL concentrated hydrochloric acid, react at 65°C for 1.5h, and use Na 2 CO 3 The solution terminated the reaction, adjusted to neutrality, then rapidly cooled to room temperature, washed, centrifuged, and dried.

[0044] 2. Preparation of esterified starch

[0045] Weigh 15g (dry basis) of the above-mentioned acid-thinned starch in pyridine solution to make a solution with a concentration of 15%, activate it at 85°C for 2h under stirring, then add 60g of octenyl succinic anhydride, and continue the reaction at 85°C for 2.5 h, after the reaction is completed, cool to room temperature, wash, centrifuge, and dry.

[0046] 3. Preparation of starch nanoparticles

[0047] Weigh 20mg of octenyl succinic acid waxy cornstarch (degree of substitution: 1.02) and dissolve it in 10mL of dimethyl su...

Embodiment 3

[0049] 1. Preparation of acid-thinned starch

[0050] Weigh 25g (dry basis) of cornstarch and disperse it in 50% ethanol solution to make starch milk with a concentration of 10%, then add 2mL of concentrated hydrochloric acid, react at 40°C for 2h, and use Na 2 CO 3 The solution terminated the reaction, adjusted to neutrality, then rapidly cooled to room temperature, washed, centrifuged, and dried.

[0051] 2. Preparation of esterified starch

[0052] Weigh 15g (dry basis) of the above-mentioned acid-thinned starch in pyridine solution to make a solution with a concentration of 20%, activate it at 95°C for 1h under stirring, then add 60g of octenyl succinic anhydride, and continue the reaction at 95°C for 2h , after the reaction is complete, cool to room temperature, wash, centrifuge, and dry.

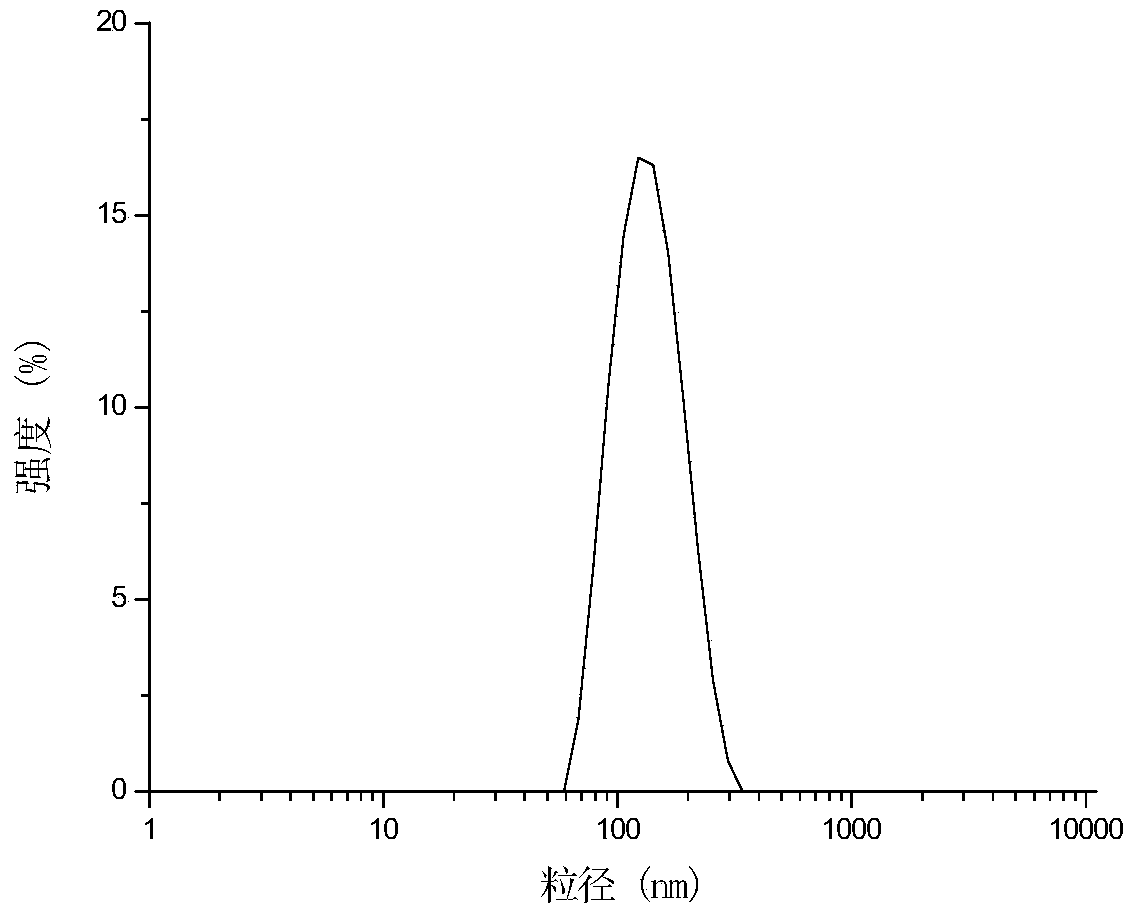

[0053] 3. Preparation of starch nanoparticles

[0054] Weigh 20 mg of octenyl succinic acid cornstarch (substitution degree is 0.84) and dissolve it in 10 mL of dimethyl sulfoxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com