A kind of warp-free mat and its processing technology

A mat and warp technology, applied in the direction of non-polymer adhesive additives, adhesive additives, film/sheet adhesive, etc., can solve the problems of bamboo mat use comfort and service life discount, general mat appearance, Bamboo strips are easy to loose and other problems, to achieve the effect of good firmness, high bonding strength and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

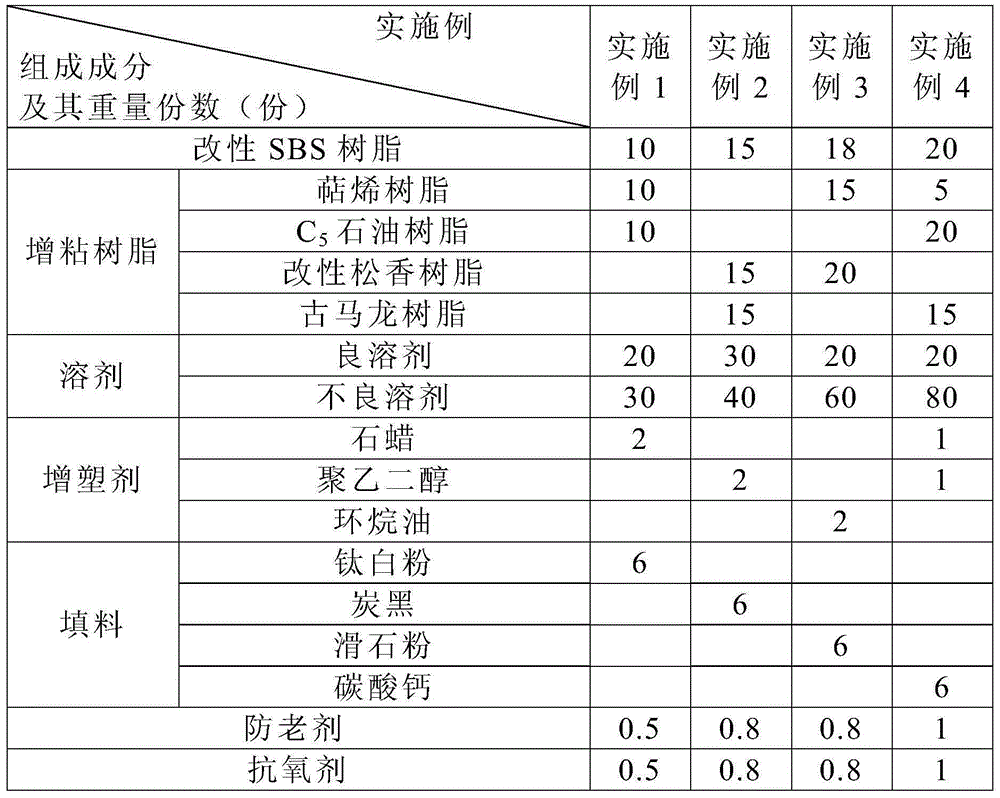

Embodiment 1

[0028] According to the composition and parts by weight of the tape adhesive in Example 1 in Table 1, the raw materials are weighed, the good solvent in the raw material is ethyl acetate, the poor solvent is n-hexane, and the particle size of the filler titanium dioxide is controlled within the range of 10-40nm. ; And use kraft paper to make tape base material, and then make tape through ordinary processing technology, standby.

[0029] Bamboo strips are used as the weft, and the bamboo strips are hot-pressed together with the adhesive tape made above at a temperature of 30°C and a pressure of 6 MPa. The hot-pressing time is 15s to obtain the main body of the mat; wherein, the width of the adhesive tape is 1cm, and the adhesive tape The distance from the tape is 4cm. Then arrange the trimming with a uniform width cut around the main body of the mat, wrap the cross-section of the mat main body with the matting cloth, make the matting cloth symmetrical on the upper and lower sid...

Embodiment 2

[0031] According to the composition and parts by weight of the tape adhesive in Example 2 in Table 1, the raw materials are weighed. In the raw materials, the good solvent adopts cyclohexane, the poor solvent adopts petroleum ether, and the particle size of the filler titanium dioxide is controlled within the scope of 40-80nm. ; And use non-woven fabrics to make adhesive tape substrates, and then make adhesive tapes through ordinary processing techniques for future use.

[0032] Bamboo strips are used as the weft, and the bamboo strips are hot-pressed together with the adhesive tape made above at a temperature of 40°C and a pressure of 5 MPa. The hot-pressing time is 12s to obtain the main body of the mat; wherein, the width of the adhesive tape is 2cm, and the adhesive tape The distance from the tape is 5cm. Then arrange the trimming with a uniform width cut around the main body of the mat, wrap the cross-section of the mat main body with the matting cloth, make the matting c...

Embodiment 3

[0034] According to the composition and parts by weight of the tape adhesive in Example 3 in Table 1, the raw materials are weighed, the good solvent in the raw material is ethyl acetate, the poor solvent is solvent gasoline, and the particle size of the filler titanium dioxide is controlled within the scope of 50-100nm. ; And adopt PVC film to make adhesive tape base material, then make adhesive tape through ordinary processing technology, standby.

[0035] Bamboo strips are used as the weft, and the bamboo strips are hot-pressed together with the adhesive tape made above at a temperature of 50°C and a pressure of 4 MPa. The hot-pressing time is 8s to obtain the main body of the mat; wherein, the width of the adhesive tape is 2cm, and the adhesive tape The distance from the tape is 5cm. Then arrange the matting with uniform width cut around the main body of the mat, wrap the cross-section of the mat main body with the matting cloth, make the matting cloth symmetrically on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com