Antrodia mycelium flavor soft sweet and processing method thereof

A technology of mycelia and processing methods of Antrodia camphorata, applied in the confectionary industry, confectionery, food preparation, etc., can solve the problem of high sugar content and achieve the effect of soft and elastic taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

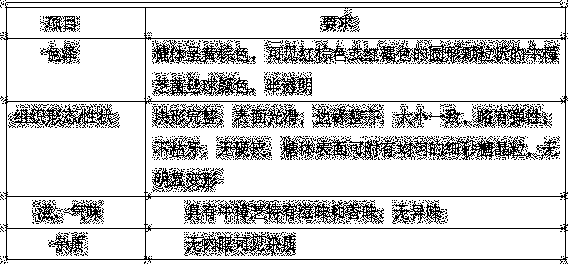

[0027] Among them, fresh Antrodia mycelium 10%-27%, white sugar 10%-20%, glucose syrup 0-20%, isomaltooligosaccharide 16%-30%, maltodextrin 20%-30%, agar 2%- 6%, carrageenan 1%-3%, the sum of the above-mentioned main raw material mass percentages is 100%; the auxiliary materials are calculated based on the total weight of the main raw materials, of which citric acid 0.1%-0.3%, Vc 0.5%-2.0%, lemon Sodium sorbate 0.2%-0.8%, Potassium sorbate 0.02%-0.1%.

[0028] Collect 15kg of fresh, pollution-free mycelia of Antrodia camphorata for subsequent use. Mix 4kg of agar, 2kg of carrageenan and 14.5kg of white sugar with 20 times the amount of water, and heat to dissolve until the agar and carrageenan completely absorb water and swell and the white sugar is completely dissolved for later use. At this time, the temperature of the sol is 85°C-95°C . Then mix 26.5kg of isomaltooligosaccharides, 21.0kg of maltodextrin and 17.0kg of glucose syrup and add 19.35kg of water to heat and diss...

Embodiment 2

[0030] Collect 27kg of fresh, pollution-free mycelia of Antrodia camphorata for subsequent use. Mix 6kg of agar, 3kg of carrageenan and 10kg of white sugar with 20 times the amount of water added, and heat to dissolve until the agar and carrageenan completely absorb water and swell and the white sugar completely dissolves. Then mix 24kg of isomaltooligosaccharides, 20kg of maltodextrin and 10kg of glucose syrup and add 19.2kg of water to heat and dissolve. At this time, the sugar melting temperature is the same as that of the sol. After the sugar is dissolved, add the glue solution and continue to cook. The cooking temperature is 105°C-110°C. Stir slowly while boiling. When the concentration of the material liquid is about 75%, add 0.8kg of sodium citrate to adjust the pH value to 5.0-5.5 , add 27kg Antrodia antrodia mycelium and 0.1kg potassium sorbate, stir evenly and continue to cook until the final concentration of the liquid is 80%-85%. When cooling off the fire to 80°C-9...

Embodiment 3

[0032] Collect 10.5kg of fresh, non-polluted mycelia of Antrodia camphorata for subsequent use. Mix 3kg of agar, 1.5kg of carrageenan and 10kg of white sugar with 20 times the amount of water, and heat to dissolve until the agar and carrageenan completely absorb water and swell and the white sugar is completely dissolved for later use. The temperature of the sol is 85°C-95°C . Then mix 30kg of isomaltooligosaccharides, 25kg of maltodextrin and 20kg of glucose syrup and add 25.5kg of water to heat and dissolve. At this time, the sugar melting temperature is the same as that of the sol. After the sugar is dissolved, add the glue solution and continue to boil. The boiling temperature is 105°C-110°C. Stir slowly while boiling. When the concentration of the material liquid is about 75%, add 0.4kg of sodium citrate to adjust the pH value to 5.0-5.5 , add 10.5kg Antrodia mycelium balls and 0.04kg potassium sorbate, stir evenly and continue to cook until the final concentration of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com