A substrate with magnetic nanowires being arranged on the surface and a preparation method of the substrate

A magnetic nanometer and nanowire technology, applied in the fields of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve problems such as expensive raw materials, disorderly distribution of nanowires, and inability to form ordered arrays. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

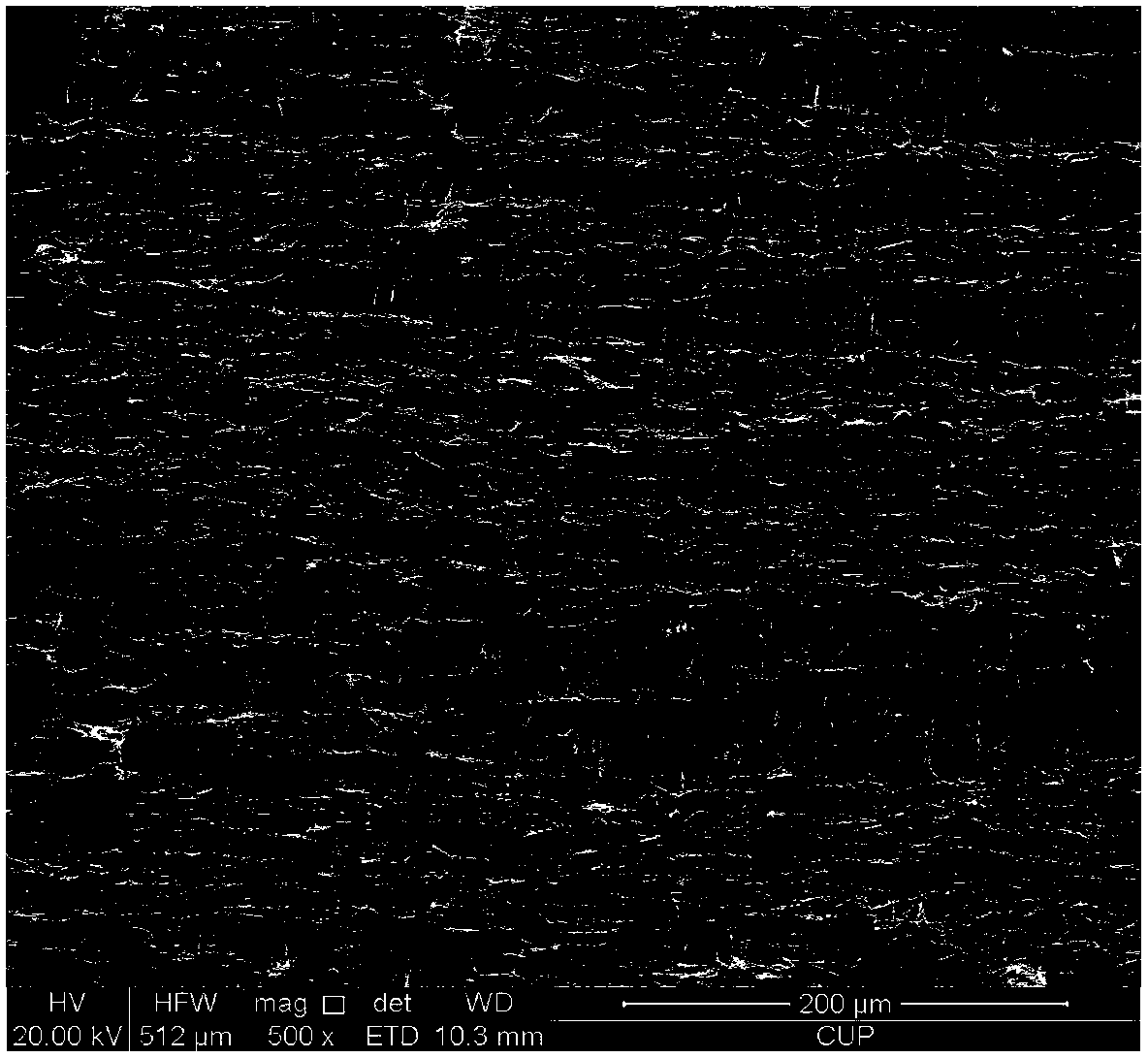

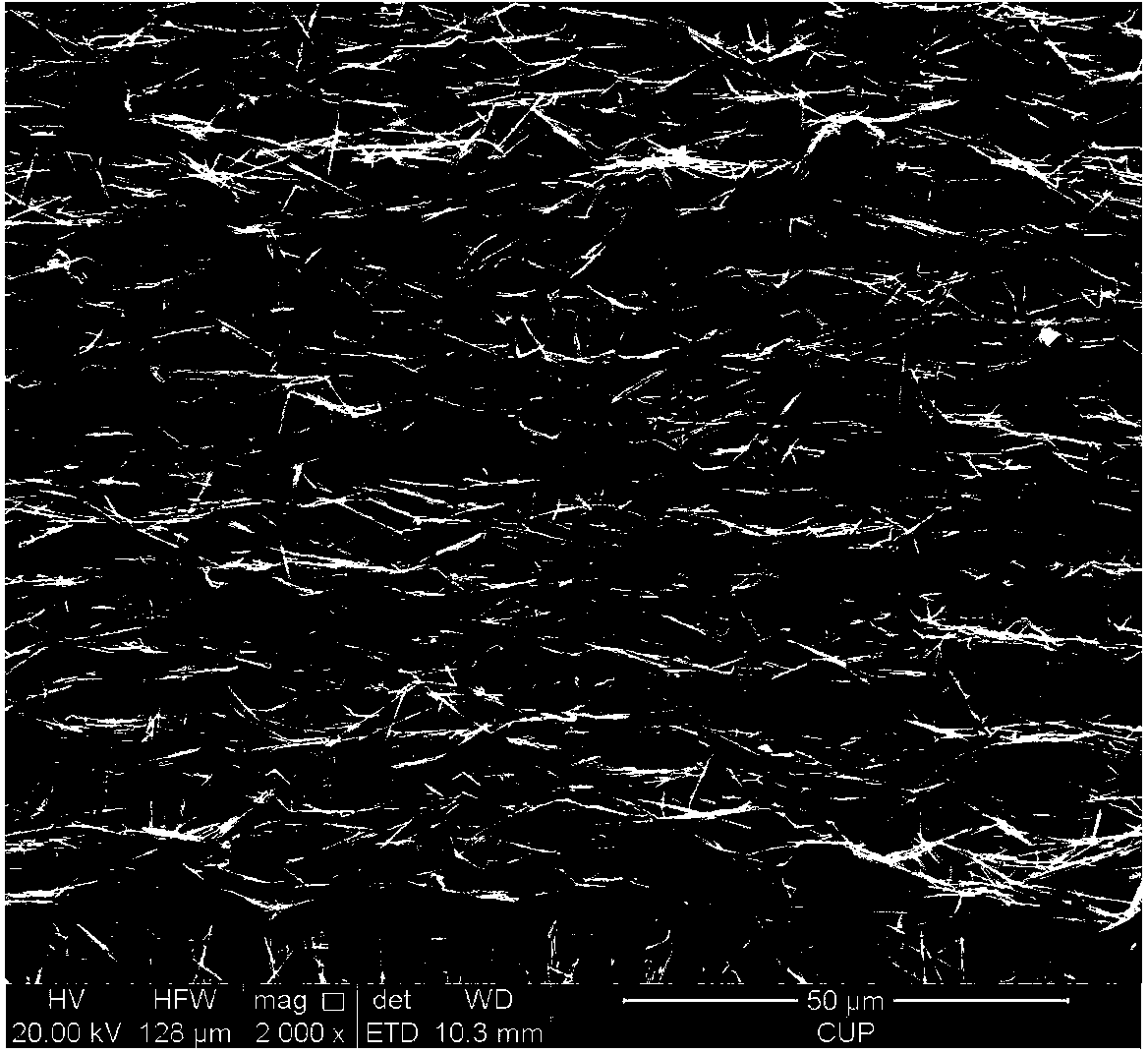

[0058] This embodiment provides a substrate with nanowires arranged on the surface and a preparation method thereof. 2 layer), the preparation method comprises the steps:

[0059] Directly growing Ni nanowires in anodized aluminum template by electrochemical deposition: before electroplating, a gold film is first plated on the back of the template as an electrode;

[0060] To the reaction solution (containing NiSO with a concentration of 0.4mol / L) 4 ·6H 2 O and 0.6mol / L H 3 BO 3 ), add dilute sulfuric acid solution, pH value is adjusted to 3;

[0061] Place the template in the reaction solution at 6 mA / cm 2 The constant current for 2min reaction, then keep 3mA / cm 2 The reaction was carried out at constant current for 3h to obtain nanowires with a length of 50μm;

[0062] Put the template with the nanowire material attached to it into the prepared aqua regia, soak it for 5-10min, and dissolve the gold film on the back of the template;

[0063] The template for dissolvin...

Embodiment 2

[0067] This embodiment provides a substrate with nanowires arranged on the surface and a preparation method thereof. 2 layer), the preparation method comprises the steps:

[0068] Directly growing Ni nanowires in anodized aluminum template by electrochemical deposition: before electroplating, a gold film is first plated on the back of the template as an electrode;

[0069] To the reaction solution (containing NiSO with a concentration of 0.4mol / L) 4 ·6H 2 O and 0.6mol / L H 3 BO 3 ), add dilute sulfuric acid solution, pH value is adjusted to 3;

[0070] Place the template in the reaction solution at 6 mA / cm 2 The constant current was used for 2min reaction, keeping 3mA / cm 2 The reaction was carried out at constant current for 3h to obtain nanowires with a length of 50μm;

[0071] Put the template with the nanowire material attached to it into the prepared aqua regia, soak it for 5-10min, and dissolve the gold film on the back of the template;

[0072] The template for di...

Embodiment 3

[0077] This embodiment provides a substrate with nanowires arranged on the surface and a preparation method thereof. 2 layer), the preparation method comprises the steps:

[0078] Directly growing Ni nanowires in anodized aluminum template by electrochemical deposition: before electroplating, a gold film is first plated on the back of the template as an electrode;

[0079] To the reaction solution (containing NiSO with a concentration of 0.4mol / L) 4 ·6H 2 O and H at a concentration of 0.6 mol / L 3 BO 3 ), add dilute sulfuric acid solution, pH value is adjusted to 3;

[0080] Place the template in the reaction solution at 3 mA / cm 2 The constant current was used for 1h reaction, and Ni nanowires with a length of 5μm were obtained;

[0081] Change the electrolyte to Cu ion solution (CuSO 4 Dilute sulfuric acid solution), adjust the pH value to 3 with dilute sulfuric acid, obtain Cu nanowires by electrochemical deposition, replace the electrolyte again with the electrolyte f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com