A kind of pelvic floor patch suspension belt and manufacturing method thereof

A suspension belt and patch technology, which is applied in textiles and papermaking, medical science, heating/cooling fabrics, etc., can solve the problems of edge hardening and difficult weaving width strip suspension belts, etc., achieve smooth edges, expand the scope of use and The effect that a use, the production method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

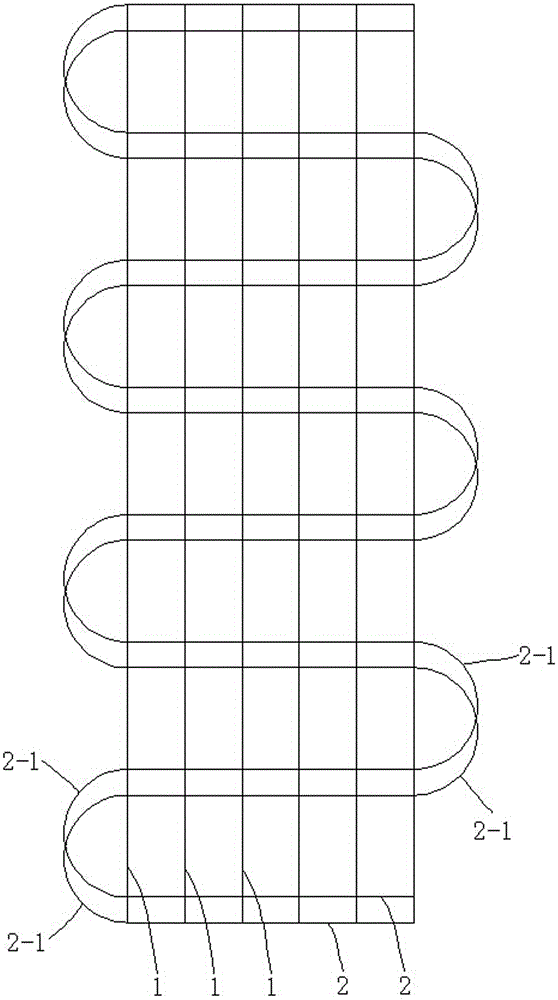

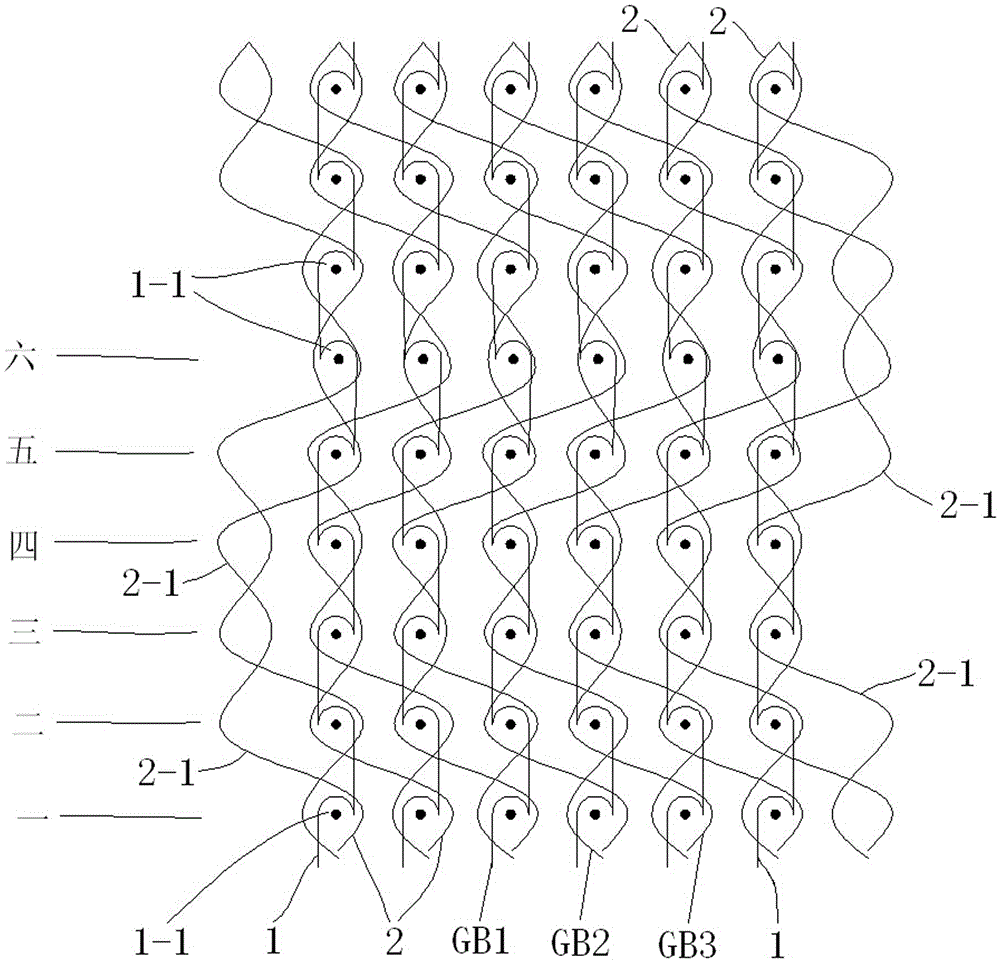

[0022] see figure 1 , 2 A pelvic bottom patch suspension belt is shown, the suspension belt is a mesh fabric formed by warp knitting of several longitudinal warp yarns 1 arranged at intervals and several transverse weft yarns 2 arranged at intervals, and each of the warp yarns 1 has the shape of A knitting chain structure of several loops 1-1 is formed in the longitudinal direction, and each of the weft yarns 2 is inserted and clamped between the loops 1-1 of the adjacent warp yarn 1 knitting chain structure, and the adjacent warp yarns 1 are connected to each other It constitutes a whole, and the weft yarns 2 on the two side edges of the whole are respectively formed with arcs 2-1.

[0023] Such as figure 1 As shown, the arc 2-1 is a semi-circular arc, and the diameter of the semi-circular arc is preferably 2-3 mm.

[0024] In the present invention, the warp yarn 1 and the weft yarn 2 are preferably polypropylene monofilaments, and the diameter of the polypropylene monofil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com