Kitchen waste pyrolysis treatment technique

A processing technology and kitchen waste heat technology, applied in the petroleum industry, special forms of dry distillation, coke ovens, etc., can solve the problem of inability to meet the needs of waste treatment, and achieve the effects of promoting microbial reproduction, soil loosening and ventilation, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

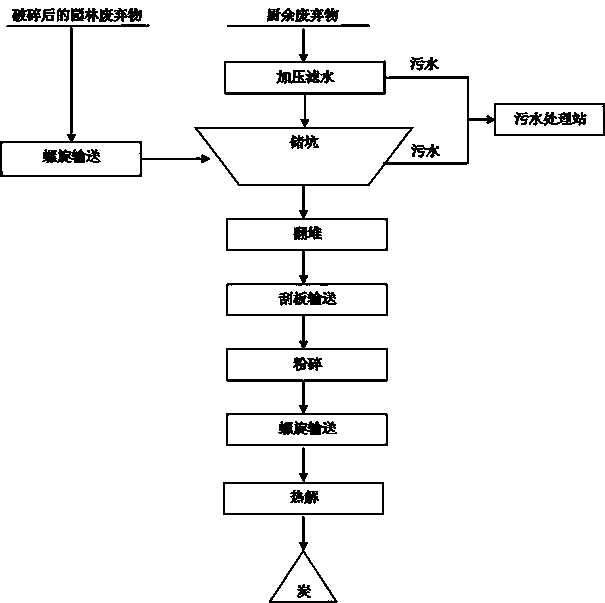

[0028] figure 1 It is a flow chart of the kitchen waste pyrolysis treatment process. Garden waste is generally the branches or leaves that are naturally dropped by the city during the greening and pruning process or plants. Generally, shearing crushers are used for preliminary crushing. The size after crushing is ≤ 30mm; The broken garden waste is transported to the feed port of the screw conveyor by a forklift, and then transported to the storage pit by the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com