Polypropylene catalyst spherical carrier and solid catalyst and preparation method thereof

A polypropylene catalyst and spherical carrier technology, applied in the production of bulk chemicals, etc., can solve the problems of low bulk density, large average pore size, affecting polymerization activity and stereoregularity, and achieve high polymerization activity and low fine powder content , the effect of good polymer particle morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) carrier preparation

[0036] Take white oil as medium, add 47.6g magnesium chloride and 59.8g ethanol (the mol ratio of ethanol and magnesium chloride is 2.6 / 1), 15g smoky silica gel (TS-610 of Cabot company, through heating N 2 blowing to remove free water), the amount of white oil was 286mL, the viscosity of white oil was 30 centipoise (20°C), and the reaction was carried out at 125°C for 2.5 hours.

[0037] Transfer the slurry containing molten alcohol and smoky silica gel obtained from the above reaction to the preheated 125°C methyl silicone oil medium; the viscosity of the methyl silicone oil is 300 centipoise (20°C), and the methyl silicone oil The dosage is 572mL; stir at 2500 rpm for 15 minutes.

[0038] Using a narrow tube with an aspect ratio of 45 at a flow rate of 300 mL / min, transfer the above-mentioned high-stirring dispersed slurry to the hexane medium that has been cooled to -30 °C in advance, and stir at a speed of 300 rpm for 15 minutes. The vol...

Embodiment 2

[0045] (1) carrier preparation

[0046] Except that the amount of fumed silica gel added is 5g, the others are the same as in Example 1. The molar ratio of ethanol to magnesium chloride in the prepared spherical carrier was analyzed by thermogravimetry to be 2.6.

[0047] (2) Preparation of spherical solid catalyst components

[0048] With embodiment 1.

[0049] (3) Propylene polymerization

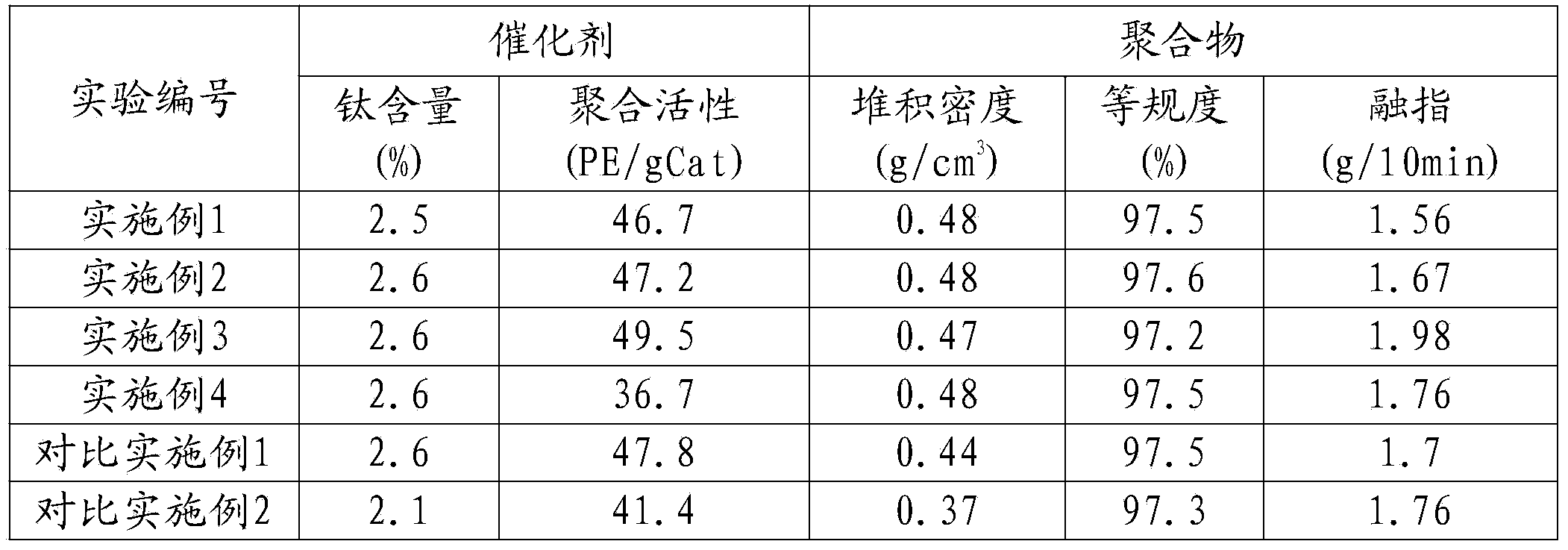

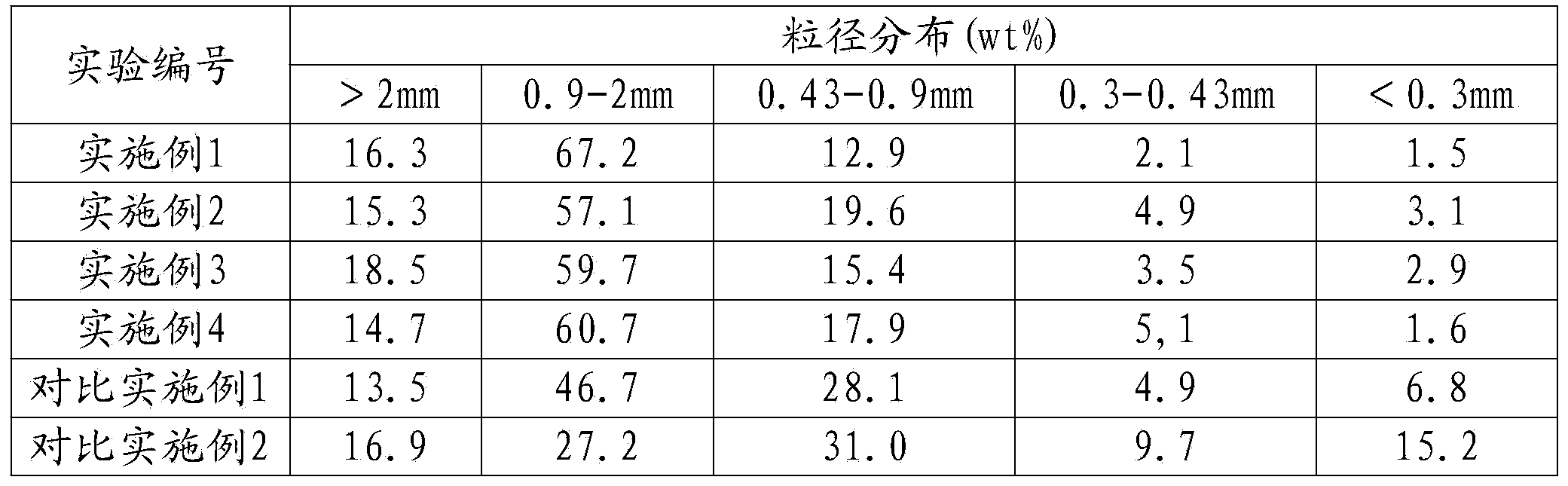

[0050] With embodiment 1. Catalyst performance and polymer powder performance test results are shown in Table 1 and Table 2.

Embodiment 3

[0052] (1) carrier preparation

[0053] Except adding 47.6g magnesium chloride and 69g ethanol (the mol ratio of ethanol and magnesium chloride is 3.0 / 1.0), other is the same as embodiment 1. The molar ratio of ethanol to magnesium chloride in the prepared spherical carrier was analyzed by thermogravimetry to be 3.0.

[0054] (2) Preparation of spherical solid catalyst components

[0055] With embodiment 1.

[0056] (3) Propylene polymerization

[0057] With embodiment 1. Catalyst performance and polymer powder performance test results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com