Bidirectional conveyer belt type conveyer

A technology of belt conveyors and conveyor belts, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems that the head and tail are not compact enough, cannot be arranged, and occupy a lot of space, so as to save space and investment costs, The effect of compact structure and compact arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

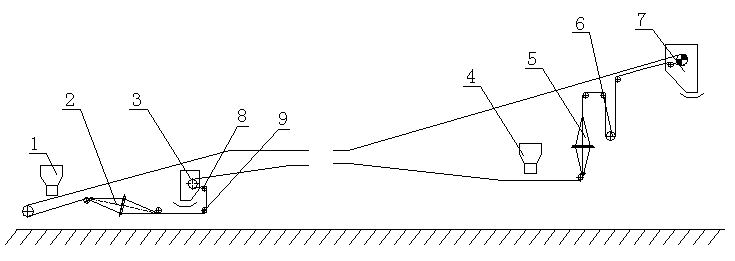

[0027] Such as figure 1 The shown two-way conveyor belt conveyor includes a tail loading mechanism 1 arranged sequentially in the moving direction of the conveyor belt; a head unloading mechanism 7; a conveyor belt tensioning device 6; a head turning device 5; Loading mechanism 4; tail return unloading mechanism 3; tail turning device 2, after the conveyor belt unloads the material to the next transportation process equipment by the tail return unloading mechanism 3, it passes through the tail return unloading drum, the first redirection The drum 8 and the second reversing drum 9 pass under the equipment in the next transportation process, and then enter the tail turning device 2; the tail turning device 2 is arranged obliquely, and after the conveyor belt is turned over by the tail turning device 2, it is transported The belt is then wound onto the tail drum. The vertical weight tensioning device 6 is vertically arranged in the return section close to the head of the belt co...

Embodiment 2

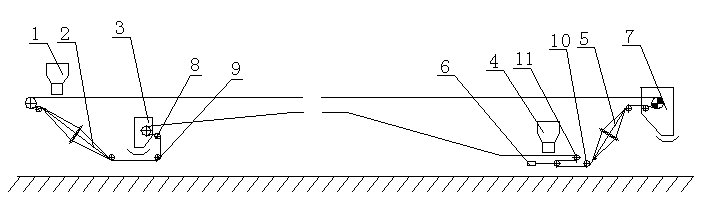

[0032] Such as figure 2 The two-way conveyor belt conveyor and belt conveyor shown include a tail loading mechanism 1 arranged in sequence in the moving direction of the conveyor belt; a head unloading mechanism 7; a head turning device 5; a tensioning device for the conveyor belt 6; head return loading mechanism 4; tail return unloading mechanism 3; tail turning device 2, after the conveyor belt unloads the material on the tail return unloading mechanism 3 to the next transportation process equipment, it passes through the tail return unloading drum 1. The first reversing drum 8 and the second reversing drum 9 pass under the equipment in the next transportation process, and then enter the tail turning device 2; the tail turning device 2 is arranged obliquely, and the conveyor belt passes through the tail turning device 2 After overturning, the conveyor belt is wound on the tail drum again. The head turning device 5 is arranged in the return section close to the head of the ...

Embodiment 3

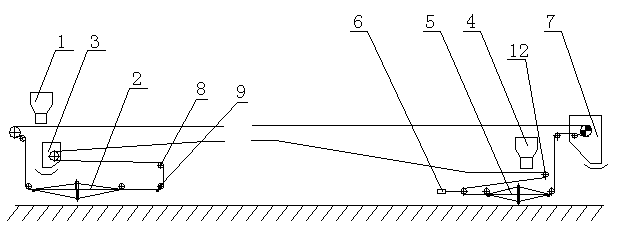

[0037] Such as image 3 The shown two-way conveyor belt conveyor and belt conveyor include a tail loading mechanism 1 arranged sequentially in the moving direction of the conveyor belt; a head unloading mechanism 7; a head turning device 5; a conveyor belt tensioning device 6; head return loading mechanism 4; tail return unloading mechanism 3; tail turning device 2, after the conveyor belt is unloaded to the next transportation process equipment by the tail return unloading mechanism 3, it passes through the tail return unloading drum , the first reversing drum 8 and the second reversing drum 9, then enter the tail turning device 2, and pass under the next transportation process equipment; the tail turning device 2 is horizontally arranged, and the conveyor belt is turned over after the tail After the device 2 is overturned, the conveyor belt winds around the tail drum after passing through the reversing drum. The head turning device 5 and the hydraulic automatic tensioning d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com