Automotive transmission case integrated with mechanical vacuum pump

A technology of mechanical vacuum pump and transmission box, which is applied in the field of automobile transmission system, can solve the problems of low system reliability and high cost, and achieve the effects of improving working conditions, driving stability and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

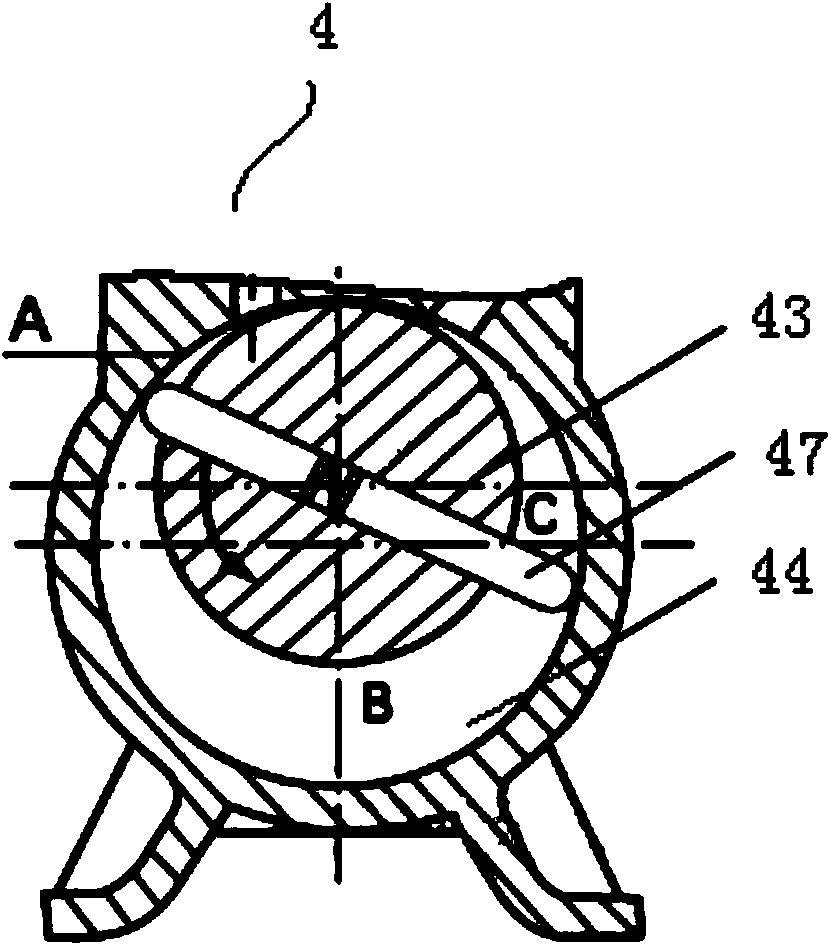

[0020] The present invention takes a vane pump as an embodiment. Although the working structure of other vacuum pumps described in this specification is slightly different, it does not affect the principle description of the present invention.

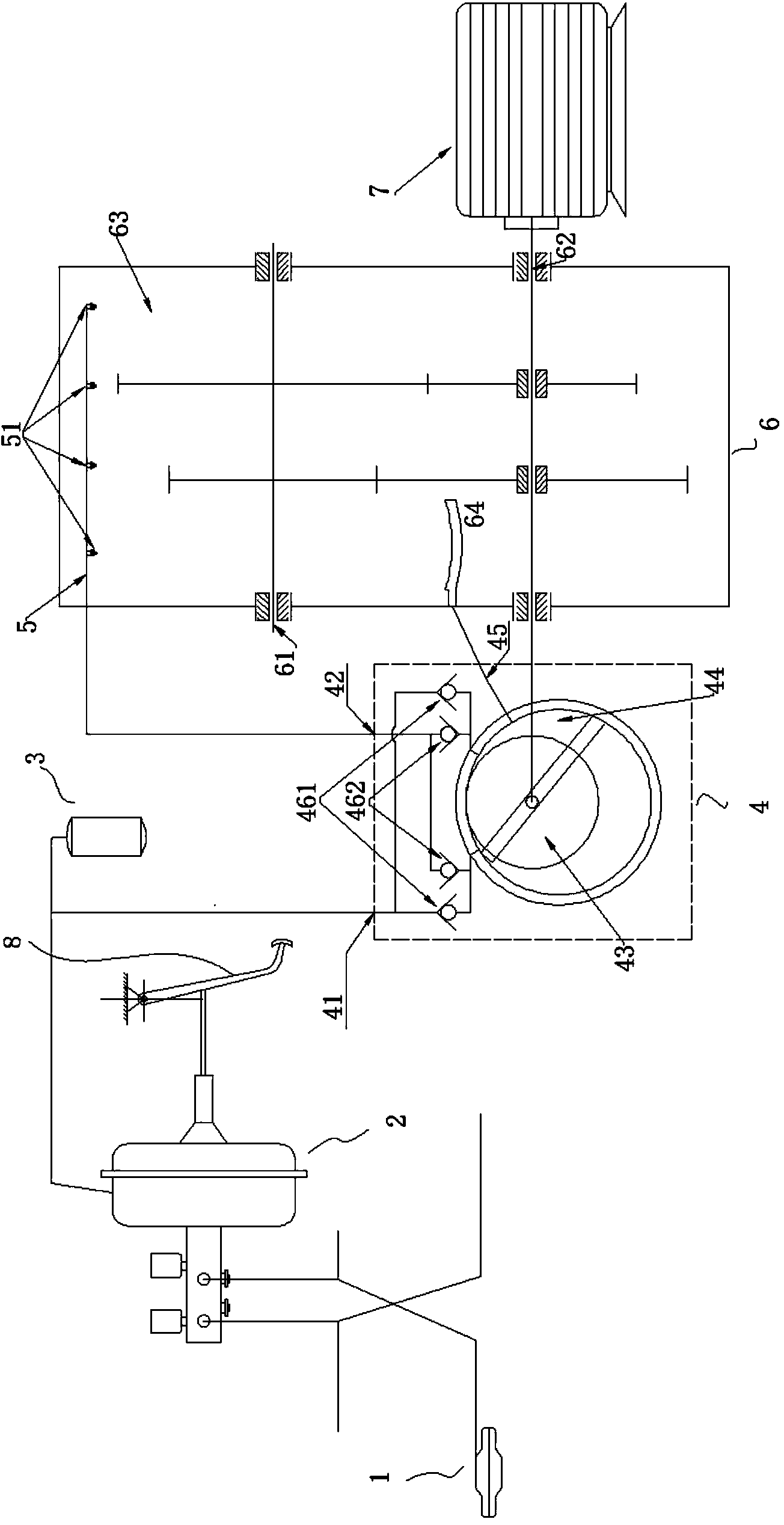

[0021] see figure 1 , the transmission box 6 in the illustration is the transmission device of the electric vehicle, one end of the input shaft 62 of the transmission box is connected with the drive motor 7, and a gear transmission mechanism is set in the cavity 63 of the transmission box to connect with the output shaft 61 of the transmission box to realize power output to Wheels, the wheels are braked through the wheel brake cylinder 1 connected to the brake system master cylinder 2, and the other end of the transmission box input shaft 62 is connected to the vacuum pump 4 to realize the integrated connection of the vacuum pump and realize the power drive of the vacuum pump.

[0022] The pipeline connection of concrete vacuum pump 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com