SMC material molding process

A process and molding technology, applied in the field of SMC material molding process, can solve the problems of high manufacturing cost and maintenance cost, non-compliance with environmental protection requirements, and large production site occupation, and achieve the requirements of reducing production site area, reducing manpower requirements, and realizing The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

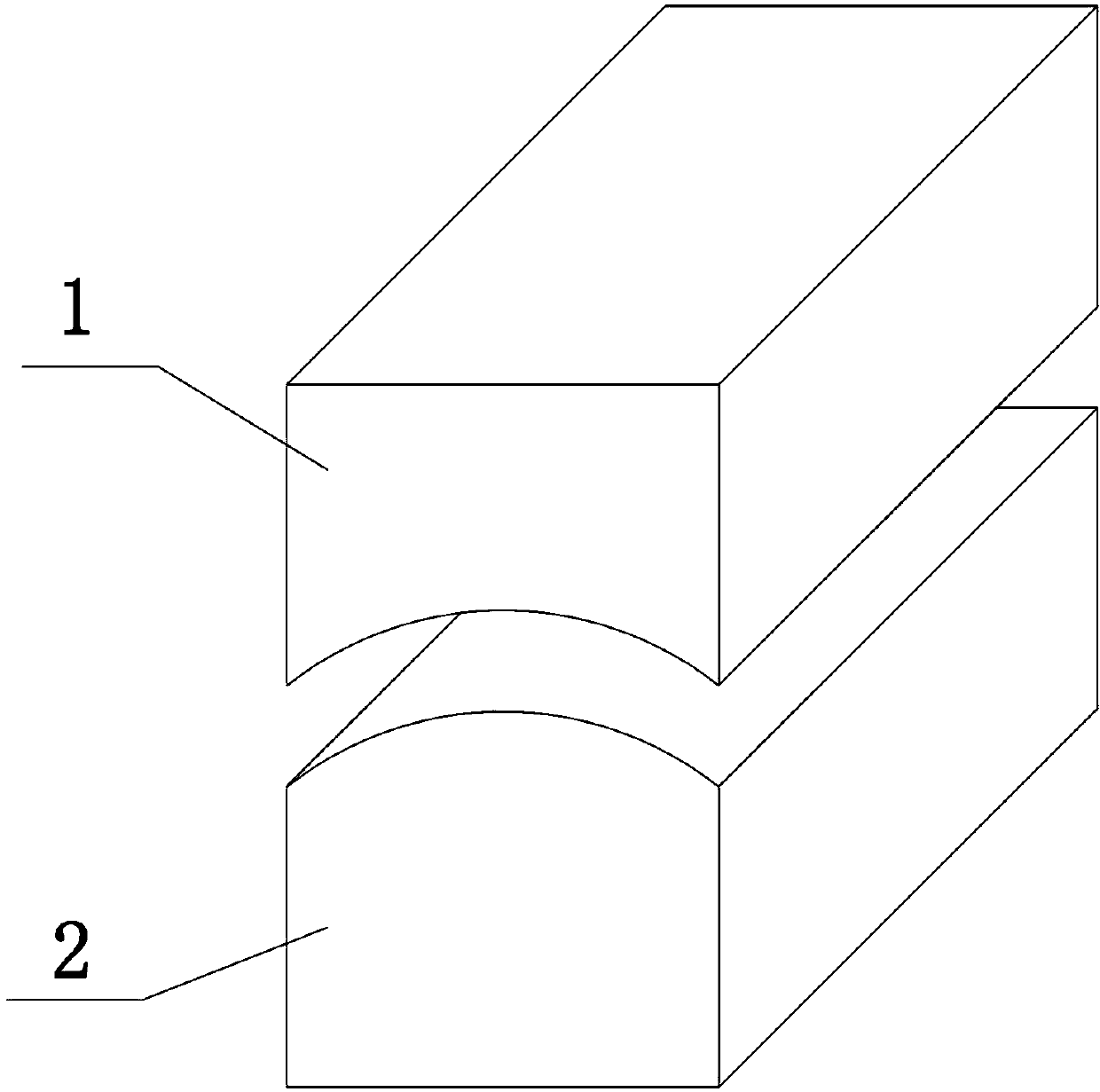

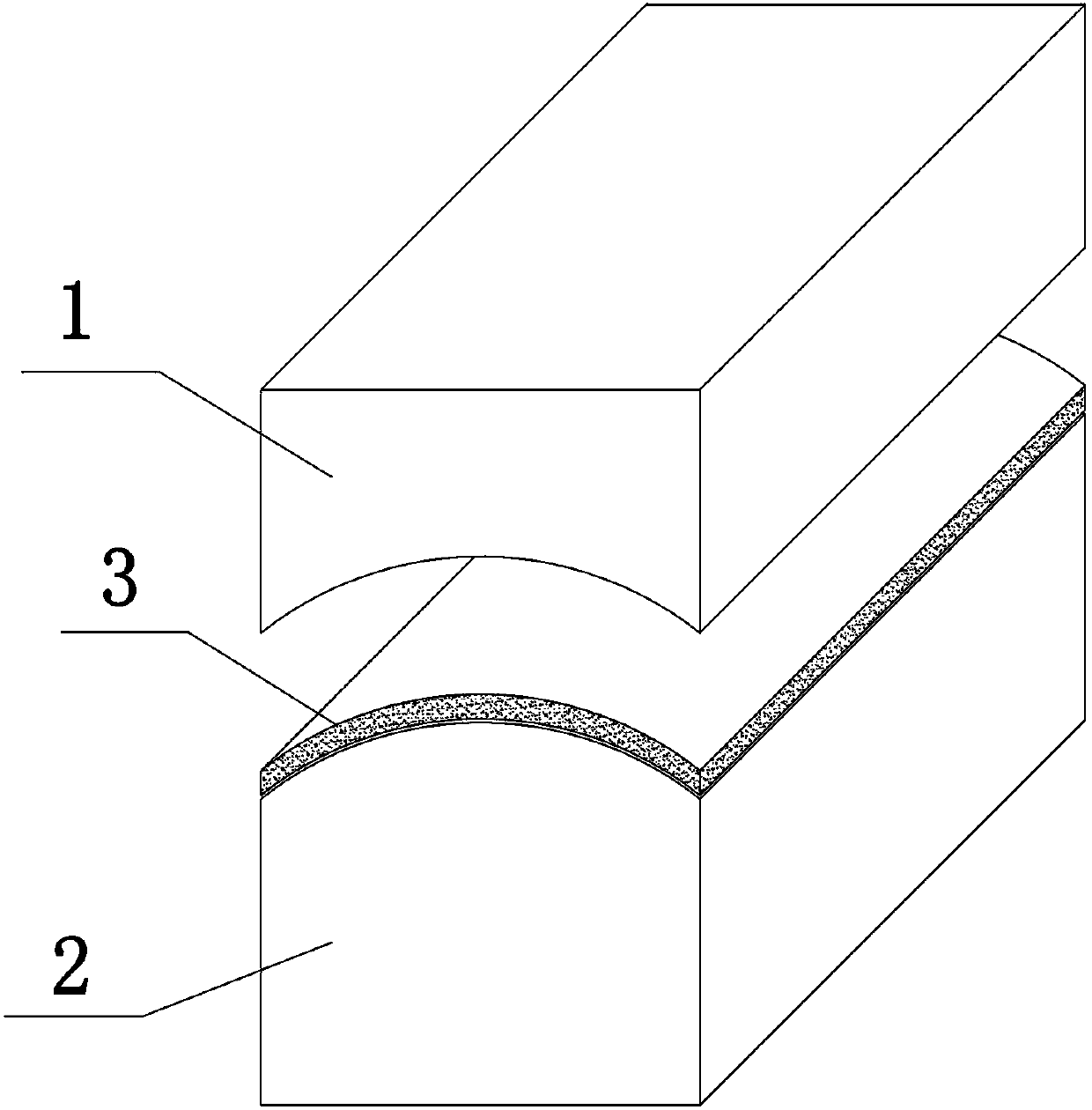

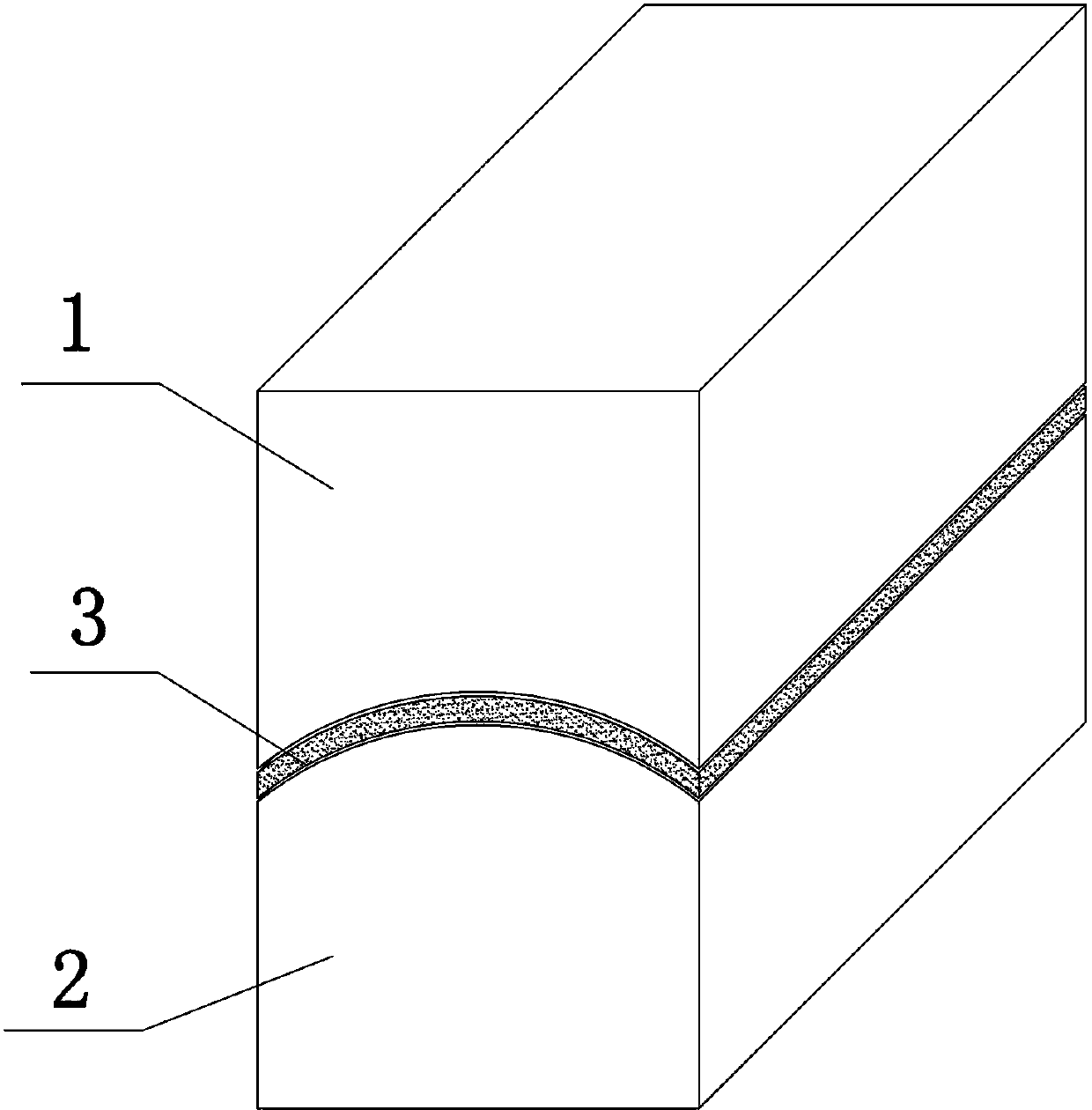

[0019] The preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings of typical products.

[0020] Such as Figure 1~4 As shown, the processing tools of the SMC material molding process include a press and a heating system. The processing tools also include a mold. A heating pipeline is installed in the mold. The mold is installed on the press. The surface of the mold cavity can be treated by electroplating. The shape of the mold The cavity is an embedded component, and the cavity and the mold are equipped with a matching connection mechanism, which allows the replacement of the cavity to achieve the purpose of producing different products under a similar design. The SMC material molding process is:

[0021] a. Unpack the SMC material, cut out a suitable size of SMC material, and then weigh it to verify whether it meets the weight requirements.

[0022] b. Turn on the heating system to continuously supply hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com