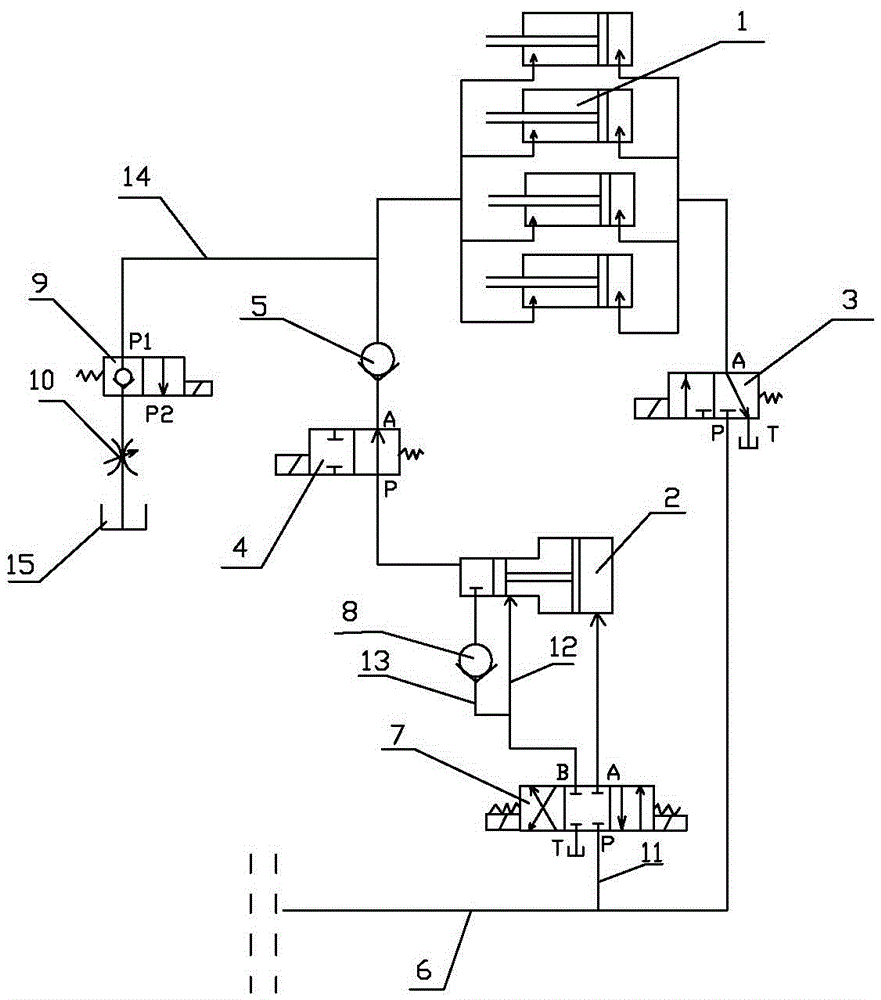

Two-platen hydraulic injection molding machine normal pressure, pressurized, high pressure mold clamping circuit

An injection molding machine, hydraulic technology, applied in the field of improvement of hydraulic high-pressure mold clamping circuit, can solve the problems of reduced system reliability, poor impact resistance and process stability, increased power consumption, etc., to achieve large driving force, fast response speed, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] figure 1 An example of the invention is given. refer to figure 1 Make the invention. The two-platen hydraulic injection molding machine has normal pressure, pressurized and high-pressure clamping circuits, including clamping hydraulic cylinder 1, boosted hydraulic cylinder 2, two-position three-way reversing valve 3, and two-position two-way reversing valve of the clamping oil circuit. 4 and clamping oil circuit check valve 5, four clamping hydraulic cylinders 1 are connected in parallel, the oil inlet P of the two-position three-way reversing valve 3 is connected to the pressure oil pipe 6 connected to the high-pressure oil pump station, and the two-position three-way reversing The upper oil port A of valve 3 communicates with the rodless cavity of four clamping hydraulic cylinders 1 through corresponding oil pipes; The reversing valve 4 and the mold clamping oil circuit check valve 5 communicate with the rod chambers of the four mold clamping hydraulic cylinders 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com