A kind of reaction device and method for preparing polyoxymethylene dimethyl ether

A polyoxymethylene dimethyl ether and reaction device technology, applied in the chemical industry, can solve problems such as poor effect, difficult to clean up, difficult to control the reaction process, etc., to solve potential safety hazards, resolve paraformaldehyde backflow, reaction temperature and pressure more manageable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, but not to limit the present application.

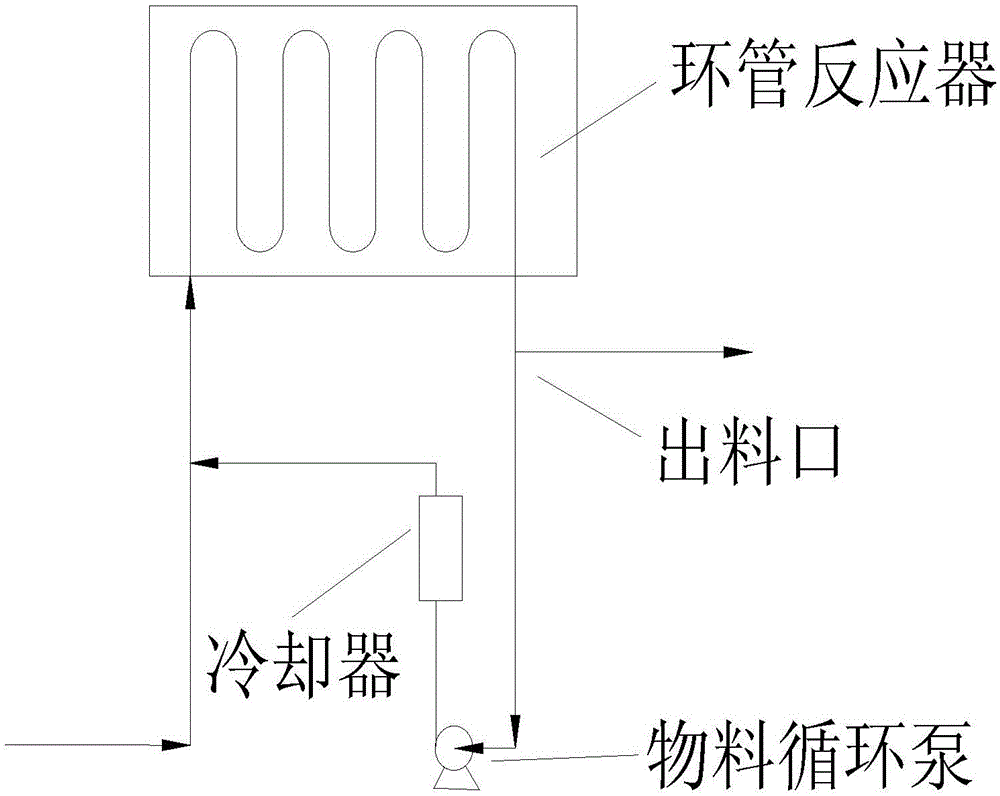

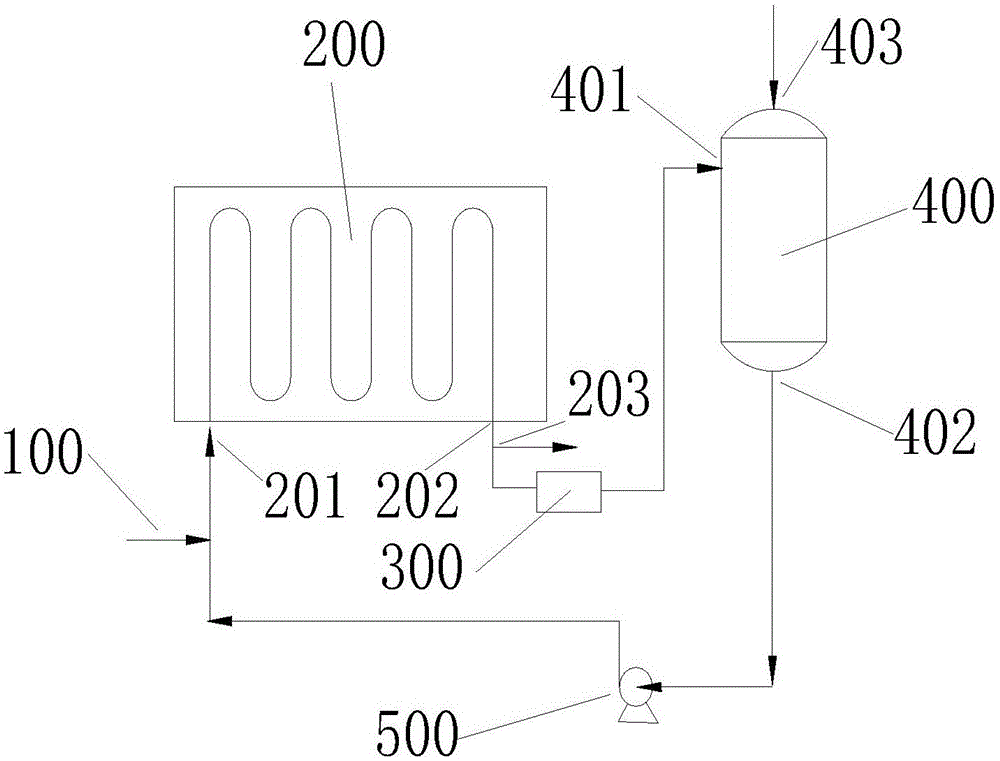

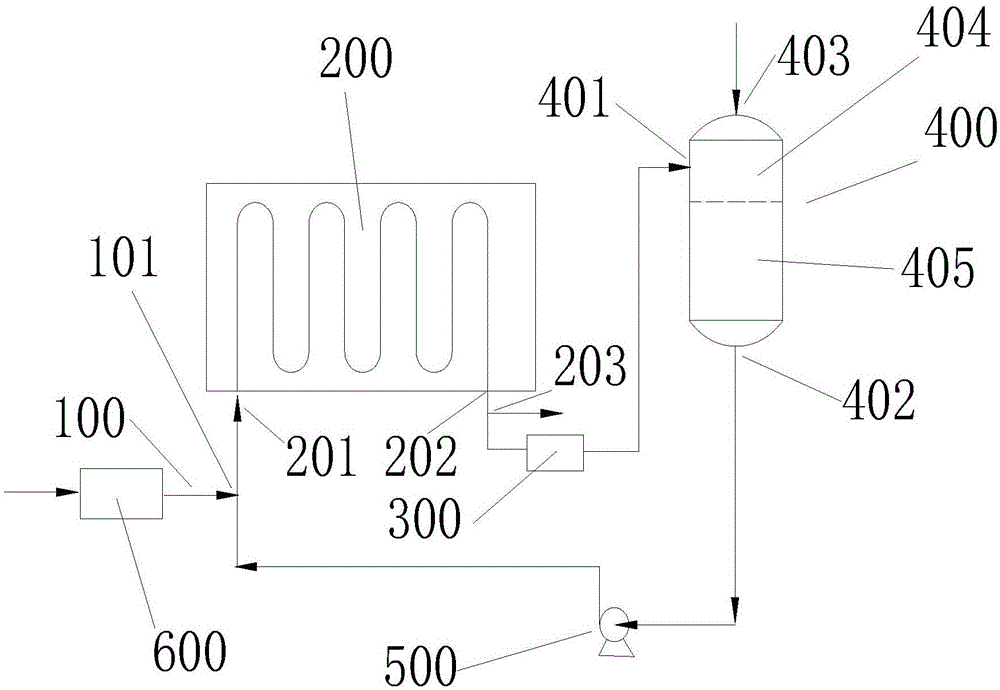

[0030] The application provides a reaction device for preparing polyoxymethylene dimethyl ether, comprising: a raw material feed pipeline, a reactor and a material circulation treatment device; the reactor is provided with a material inlet and a material outlet, and the material circulation treatment The device includes a cooler and a buffer tank; the raw material feed line is connected to the material inlet of the reactor, and the cooler is arranged between the material outlet of the reactor and the buffer tank, A branch outlet for outputting products is arranged between the material outlet and the cooler; the bottom of the buffer tank is provided with a circulating material outlet directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com