Giant salamander polypeptide beverage and preparation method thereof

A technology of giant salamander polypeptides and drinks, which is applied in food hydrolysis, food ingredients, food ingredients containing natural extracts, etc., can solve the problems that the nutritional value of giant salamanders cannot be fully utilized, and the digestive and absorption system is limited, so as to facilitate human body absorption, High nutritional value, good taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

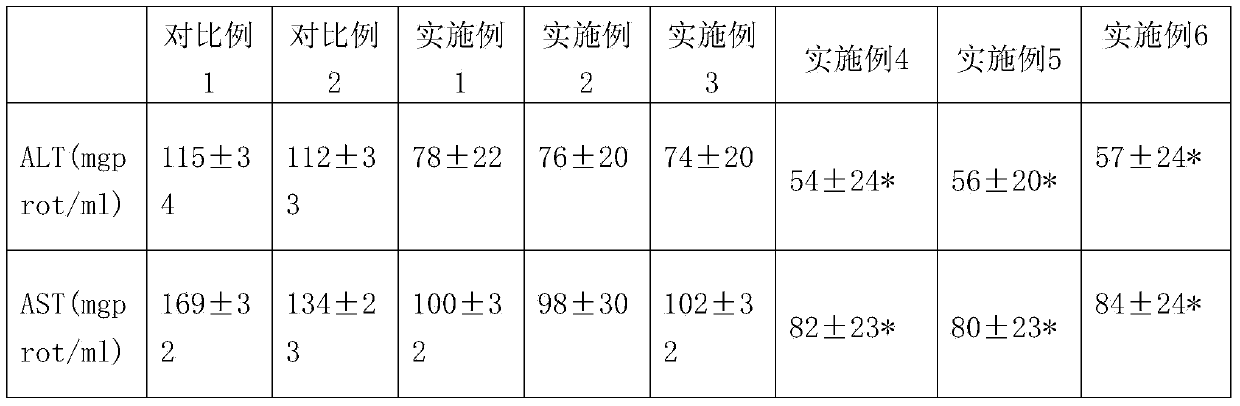

Examples

Embodiment 1

[0050] Preparation of giant salamander polypeptide: (a) Pretreatment: wash giant salamander and cut it into 0.5-2cm 3 (b) cooking: add water to the obtained giant salamander meat pieces, and cook at 111 ℃-123 ℃ for 20min-30min, until the giant salamander meat pieces are softened; (c) enzymatic hydrolysis: the material liquid band after cooking After natural cooling, the material-water ratio was adjusted to 1:2 with the mass of the raw salamander meat, and then a composite protease composed of neutral protease, papain and flavor protease was added for enzymatic hydrolysis, and the neutral protease was 50,000. U / g, the dosage is 0.5% of the mass of giant salamander meat, papain is 100,000 U / g, the dosage is 0.6% of the mass of giant salamander meat, flavor protease is composed of aminopeptidase and carboxypeptidase in a mass ratio of 3:1 , aminopeptidase and carboxypeptidase were both 15,000 U / g, and the amount of flavor protease was 0.3% of the mass of the salamander meat. The...

Embodiment 2

[0054] Preparation of giant salamander polypeptide: (a) Pretreatment: wash giant salamander and cut it into 0.5-2cm 3 (b) cooking: add water to the obtained giant salamander meat pieces, and boil at 111°C-123°C for 20min-30min, until the giant salamander meat pieces are softened; (c) enzymatic hydrolysis: the material liquid to be boiled After natural cooling under pressure, the material-water ratio was adjusted to 1:4 with the mass of the raw salamander meat, and then a composite protease consisting of neutral protease, papain and flavor protease was added for enzymatic hydrolysis, and the neutral protease was 5 Ten thousand U / g, the dosage is 1.2% of the mass of the giant salamander meat, papain is 100,000 U / g, the dosage is 1.6% of the mass of the giant salamander meat, and the flavor protease is composed of aminopeptidase and carboxypeptidase in a mass ratio of 5:1 Composition, aminopeptidase and carboxypeptidase are both 15,000 U / g, the amount of flavor protease is 1.0% o...

Embodiment 3

[0058] Preparation of giant salamander polypeptide: (a) Pretreatment: wash giant salamander and cut it into 0.5-2cm 3 (b) cooking: add water to the obtained giant salamander meat pieces, and boil at 111°C-123°C for 20min-30min, until the giant salamander meat pieces are softened; (c) enzymatic hydrolysis: the material liquid to be boiled After natural cooling under pressure, the material-water ratio was adjusted to 1:6 with the mass of the raw salamander meat, and then a composite protease composed of neutral protease, papain and flavor protease was added for enzymolysis, and the neutral protease was 5 Ten thousand U / g, the dosage is 1.5% of the mass of the giant salamander meat, papain is 100,000 U / g, the dosage is 2.0% of the mass of the giant salamander meat, and the flavor protease is composed of aminopeptidase and carboxypeptidase in a mass ratio of 4:1 Composition, aminopeptidase and carboxypeptidase are both 15,000 U / g, the amount of flavor protease is 0.8% of the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com