Exogenous pigment-free special compound feed for tachysurus fulvidraco and preparation method thereof

A technology for compound feed and yellow catfish, applied in animal feed, animal feed, application and other directions, can solve the problems of reducing the quality of yellow catfish meat, inhibiting the growth rate of yellow catfish, etc., and achieves high feed conversion efficiency and nitrogen and phosphorus emissions. Less, improve the effect of meat quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Feed raw materials after crushing: 20 parts of fish meal, 15 parts of soybean meal, 10 parts of rapeseed meal, 5 parts of cotton meal, 15 parts of corn gluten meal, 20 parts of flour, 6 parts of rice bran, 2 parts of calcium dihydrogen phosphate, multidimensional premix 0.1 part, 0.5 part of multi-mineral premix, 0.15 part of choline chloride, 0.2 part of table salt, 3 parts of soybean oil, 0.02 part of antioxidant, 0.1 part of antifungal agent, 2 parts of bentonite, 0.15 part of coated lysine, Wanshou Chrysanthemum 0.5, chlorella 0.2, alfalfa protein juice 0.1. The above-mentioned raw materials are fully mixed, then ultrafinely pulverized, and a special compound feed for yellow catfish without exogenous pigments is obtained by using a feed machine.

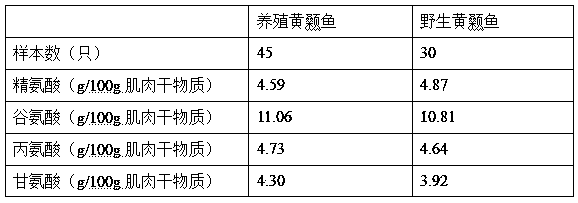

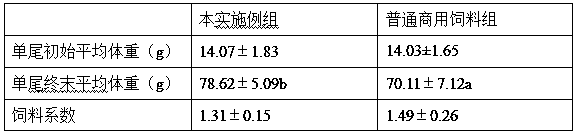

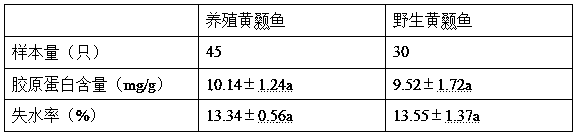

[0016] The protein content of the feed produced in this embodiment is 38.5%, the fat content reaches 7%, and the lysine content reaches 2.72%, which can fully meet the nutritional needs of the yellow catfish. The feed was...

Embodiment 2

[0021] Feed raw materials after crushing: 22 parts of fish meal, 14 parts of soybean meal, 12 parts of rapeseed meal, 5 parts of cotton meal, 14 parts of corn gluten meal, 19 parts of flour, 5 parts of rice bran, 2 parts of calcium dihydrogen phosphate, multidimensional premix 0.1 part, 0.5 part of multi-mineral premix, 0.15 part of choline chloride, 0.2 part of table salt, 3 parts of soybean oil, 0.02 part of antioxidant, 0.1 part of antifungal agent, 2 parts of bentonite, 0.1 part of coated lysine, Wanshou Chrysanthemum 0.5, chlorella 0.2, alfalfa protein juice 0.1. The above-mentioned raw materials are fully mixed, then ultrafinely pulverized, and a special compound feed for yellow catfish without exogenous pigments is obtained by using a feed machine.

[0022] The protein content of the feed produced in this embodiment is 39.0%, the fat content reaches 7.2%, and the lysine content reaches 2.80%, which can fully meet the nutritional needs of the yellow catfish.

[0023] Us...

Embodiment 3

[0032] Feed raw materials after crushing: 21 parts of fish meal, 15 parts of soybean meal, 10 parts of rapeseed meal, 6 parts of cotton meal, 15 parts of corn gluten meal, 19 parts of flour, 5 parts of rice bran, 2 parts of calcium dihydrogen phosphate, multidimensional premix 0.1 part, 0.5 part of multi-mineral premix, 0.15 part of choline chloride, 0.2 part of table salt, 3 parts of soybean oil, 0.02 part of antioxidant, 0.1 part of antifungal agent, 2 parts of bentonite, 0.12 part of coated lysine, Wanshou Chrysanthemum 0.5, chlorella 0.2, alfalfa protein juice 0.1. The above-mentioned raw materials are fully mixed, then ultrafinely pulverized, and a special compound feed for yellow catfish without exogenous pigments is obtained by using a feed machine.

[0033] The protein content of the feed produced in this embodiment is 38.8%, the fat content reaches 7.1%, and the lysine content reaches 2.78%, which can fully meet the nutritional needs of the yellow catfish.

[0034] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com