Feed for controlling fatness of grass carp

A technology of fatness and feed, applied in animal feed, animal feed, application, etc., can solve the problems of ignoring the influence of grass carp fatness, improve specific growth rate and survival rate, reduce bait coefficient, and nutritional components balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

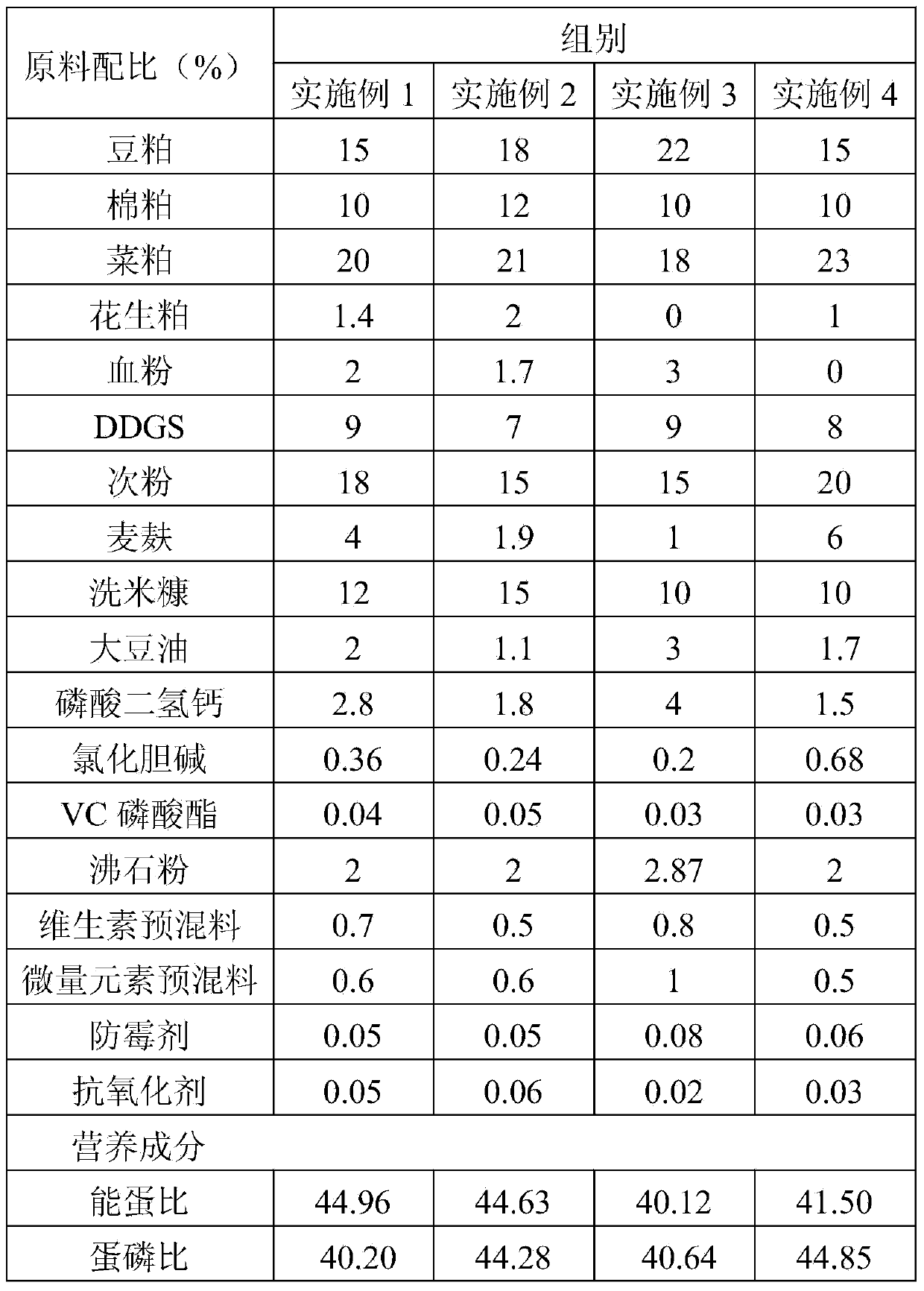

Embodiment 1

[0031] In parts by weight, the feed consists of the following components: soybean meal 15, cotton meal 10, rapeseed meal 20, peanut meal 1.4, blood meal 2, DDGS 9, secondary meal 18, wheat bran 4, washed rice bran 12, soybean oil 2 , calcium dihydrogen phosphate 2.8, choline chloride 0.36, VC phosphate 0.04, zeolite powder 2, vitamin premix 0.7, trace element premix 0.6, antifungal agent 0.05, antioxidant 0.05.

[0032] The preparation method is as follows:

[0033] (1) After removing impurities from soybean meal, rapeseed meal, cotton meal, peanut meal, DDGS, washed rice bran, subflour and wheat bran, they are respectively crushed into powder and passed through a 60-mesh sieve; then the powders are mixed evenly to obtain powder I ;

[0034] (2) The powder I prepared in step (1) is mixed with soybean oil, choline chloride, calcium dihydrogen phosphate, VC phosphate, blood meal, zeolite powder, vitamin premix, trace element premix, anti-fungal agent Mix well with antioxidant ...

Embodiment 2

[0038] In parts by weight, the feed consists of the following components: soybean meal 18, cotton meal 12, rapeseed meal 21, peanut meal 2, blood meal 1.7, DDGS 7, secondary meal 15, wheat bran 1.9, washed rice bran 15, soybean oil 1.1 , calcium dihydrogen phosphate 1.8, choline chloride 0.24, VC phosphate 0.05, zeolite powder 2, vitamin premix 0.5, trace element premix 0.6, antifungal agent 0.05, antioxidant 0.06.

[0039] The preparation method is the same as in Example 1.

Embodiment 3

[0041] In parts by weight, the feed consists of the following components: soybean meal 22, cotton meal 10, rapeseed meal 18, peanut meal 0, blood meal 3, DDGS 9, secondary meal 15, wheat bran 1, washed rice bran 10, soybean oil 3 , calcium dihydrogen phosphate 4, choline chloride 0.2, VC phosphate 0.03, zeolite powder 2.87, vitamin premix 0.8, trace element premix 1, antifungal agent 0.08, antioxidant 0.02.

[0042] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com