Tire with tread having improved snow and dry traction

A tread and tire technology, applied in the direction of tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve problems such as failure to provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

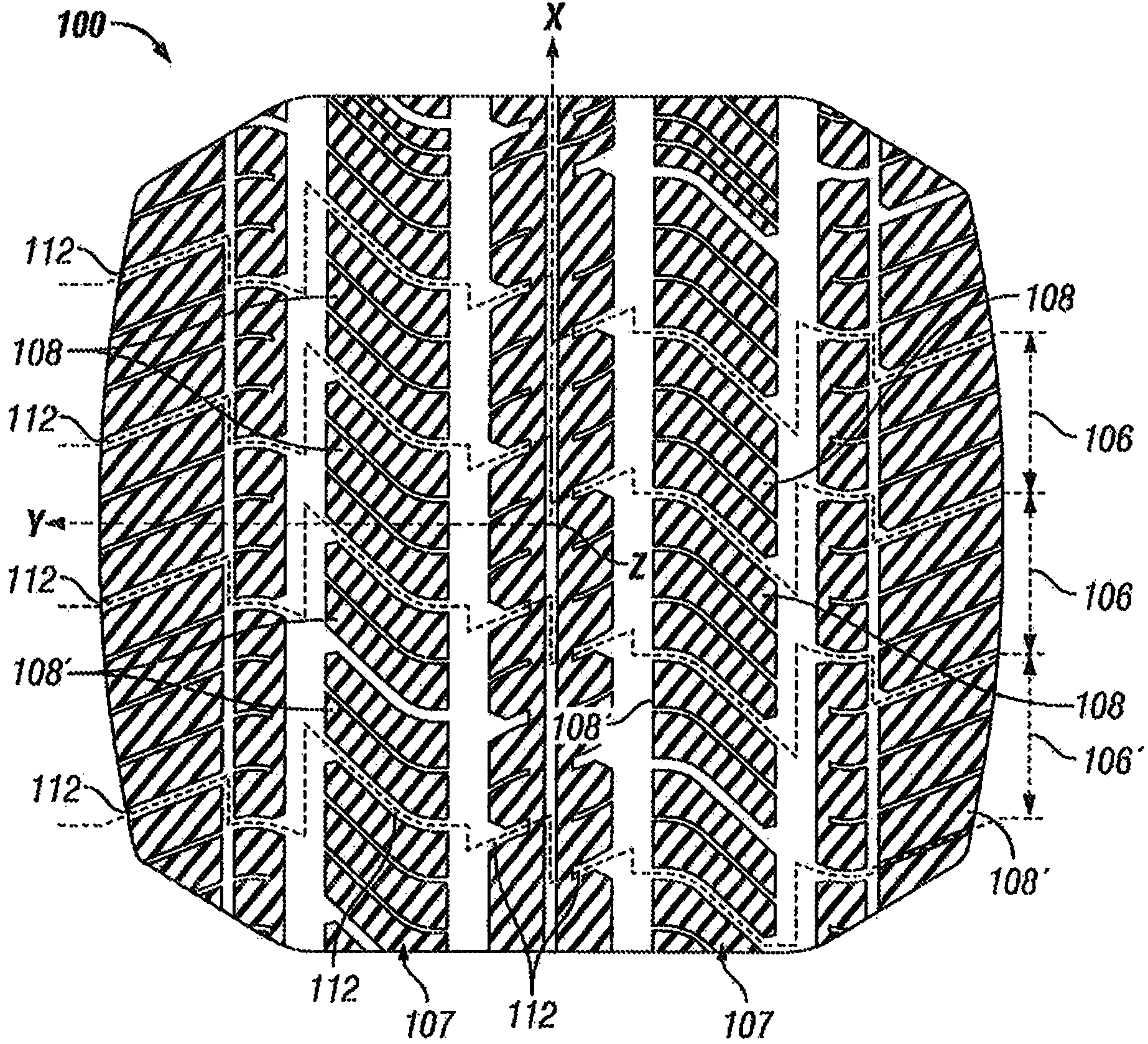

[0088] Embodiments of the present invention include configurations that modify the stiffness of the tread elements found in the tread of a tire in order to break the compromise that occurs between snow and dry traction performance. It should be noted that these desired properties may be satisfactorily obtained depending on the application of one, all or any combination of the embodiments described below. Moreover, these techniques can be used on many tread elements including tread blocks and ribs.

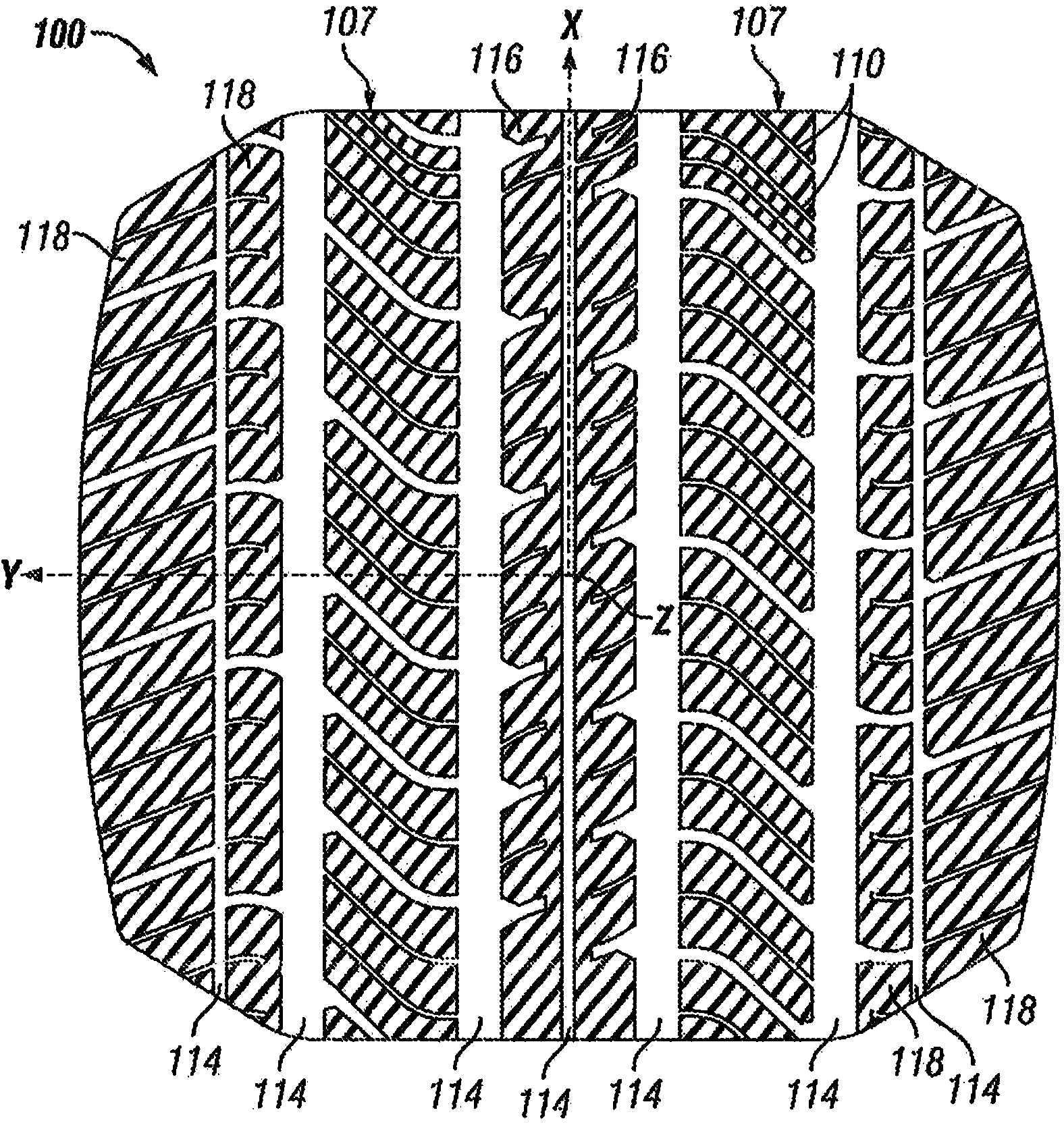

[0089] See you again figure 1 , an overhead view of the footprint of the tire tread that was previously used on all-season tires can be seen. This is the 205 / 55R16 size tire currently marketed under the trademark PRIMACY MXV4 by the assignee of the present invention. The tire has six longitudinal grooves 114 , two middle rows 107 of tread blocks 108 , two central ribs 116 and four shoulder rows 118 of tread blocks 108 . The width of the longitudinal grooves is in the range of 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com