Device for filling magazines for electrode caps

A technology for electrode caps and material storage, which is applied in the field of devices in material storage, and can solve problems such as uneliminated process interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

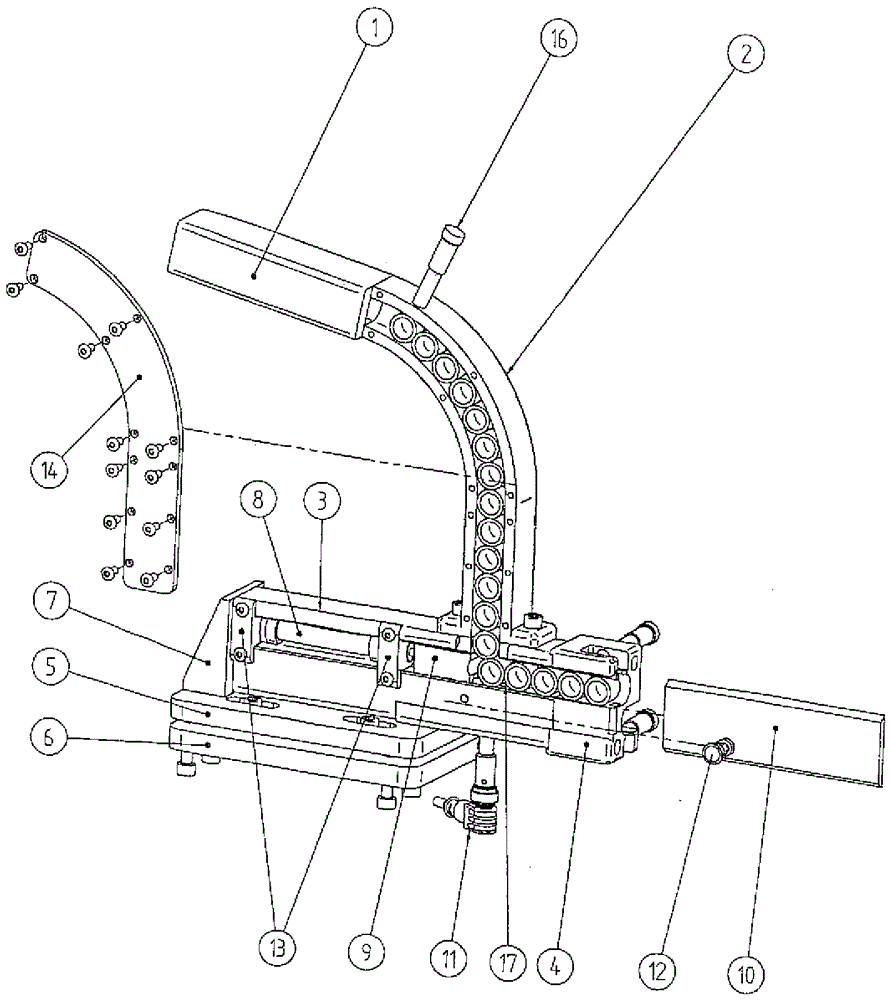

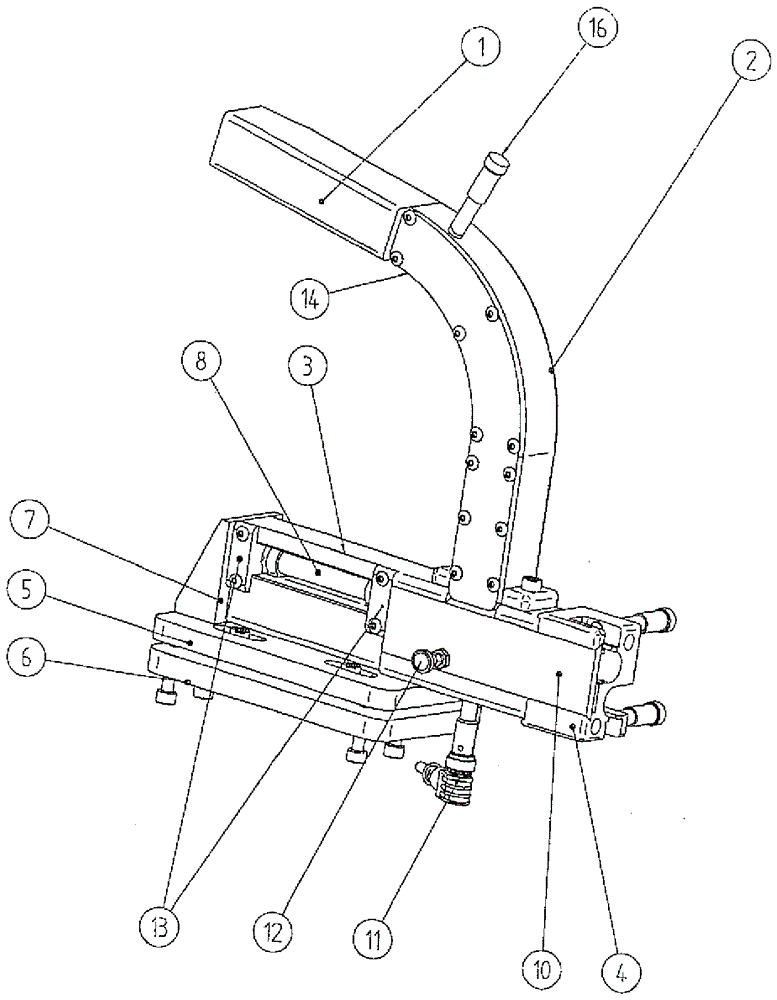

[0022] The device 3 according to the invention comprises an electrode cap turning channel 1 connected at one end to a screw conveyor.

[0023] Electrode caps are pre-positioned and conveyed by a screw conveyor. The electrode cap rests with its end face provided with holes at the end of the screw conveyor.

[0024] From this position, the electrode cap is transferred to the electrode cap rotation channel 1 in a defined position.

[0025] In this case, the electrode cap rotation channel 1 is designed such that the electrode cap is rotated by 90° about its Z-axis.

[0026] Here, the electrode cap rotating channel 1 is preferably fixedly connected to the screw conveyor, so as to transmit the vibration of the screw conveyor to the electrode cap rotating channel 1 and to better transport the electrode caps.

[0027] The other end of the electrode cap rotating channel 1 is arranged to face the upper end of the guide shaft 2 .

[0028] Here, the electrode cap rotation channel 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com