A dual-chamber controllable pressure high-temperature quenching hot forming system and process

A dual-chamber, high-temperature technology, used in manufacturing tools, glass tempering, glass transportation equipment, etc., can solve problems such as inability to accurately control process parameters, difficulty in glass forming analysis, deterioration of forming effects, etc., to ensure operational safety, The effect of ensuring batch consistency and process reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

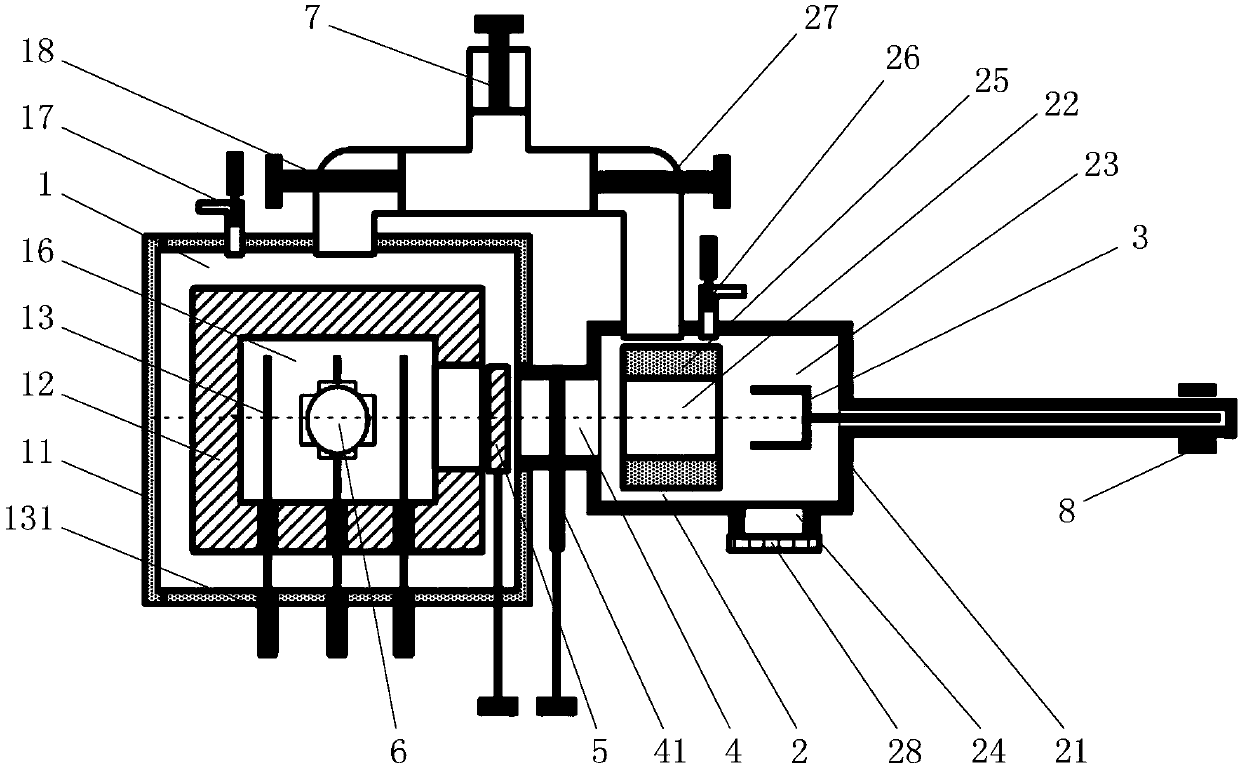

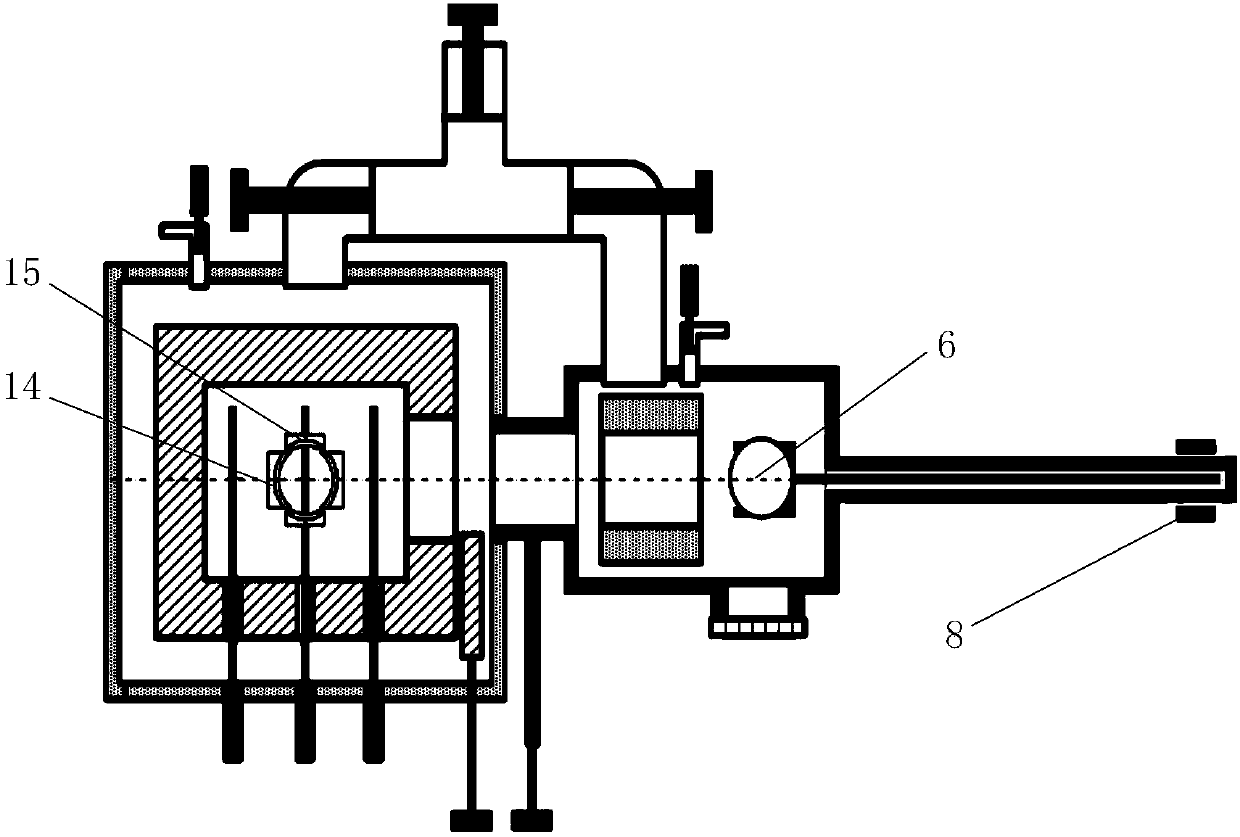

[0030] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a double-chamber controllable pressure high-temperature quenching thermoforming system, which includes a high-temperature chamber 1, a low-temperature chamber 2 and a feeding rod 3; the high-temperature chamber 1 and the low-temperature chamber 2 pass through The middle chamber 4 is connected, and a vacuum baffle 41 is arranged in the middle chamber 4, which can separate the high-temperature chamber 1 and the low-temperature chamber 2 to maintain different vacuum degrees; the high-temperature chamber 1 is close to the low-temperature chamber 2 is provided with a heat insulation baffle 5 to block the heat radiation and heat transfer from the high temperature chamber 1 to the low temperature chamber 2; And the stroke of the feeding rod 3 can pass through the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com