Sand box trolley and casting production method

A sand box trolley and production method technology, which is applied in foundry workshops, casting equipment, equipment for transporting casting molds, etc., can solve the problem that the labor intensity of workers has not been effectively reduced, the automatic production of castings has not been realized, sand box handling and movement difficulties, etc. problems, to achieve process stability and reliability assurance, good economic benefits, and low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

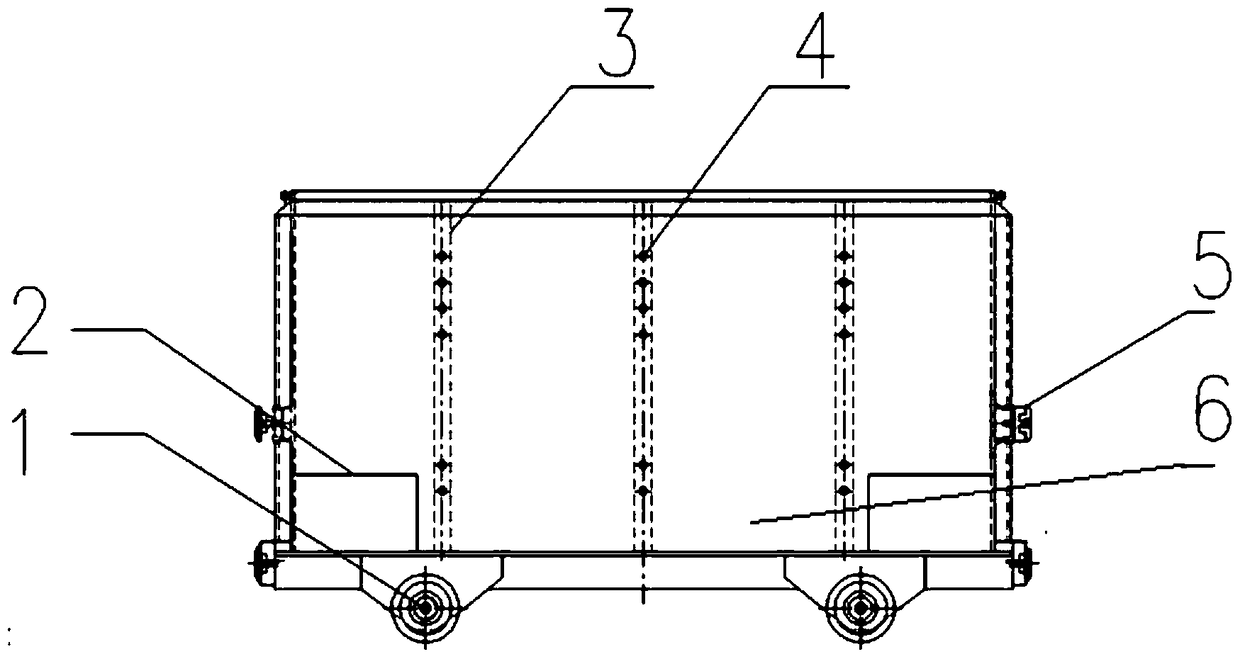

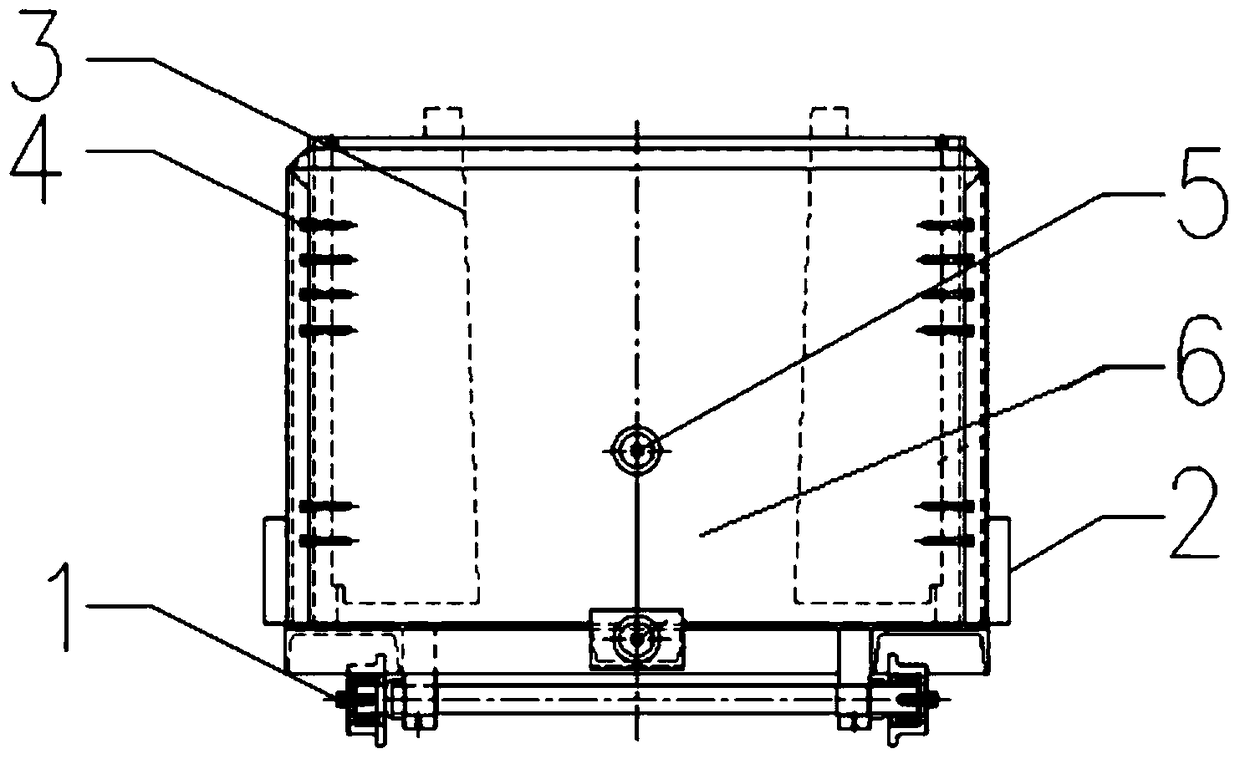

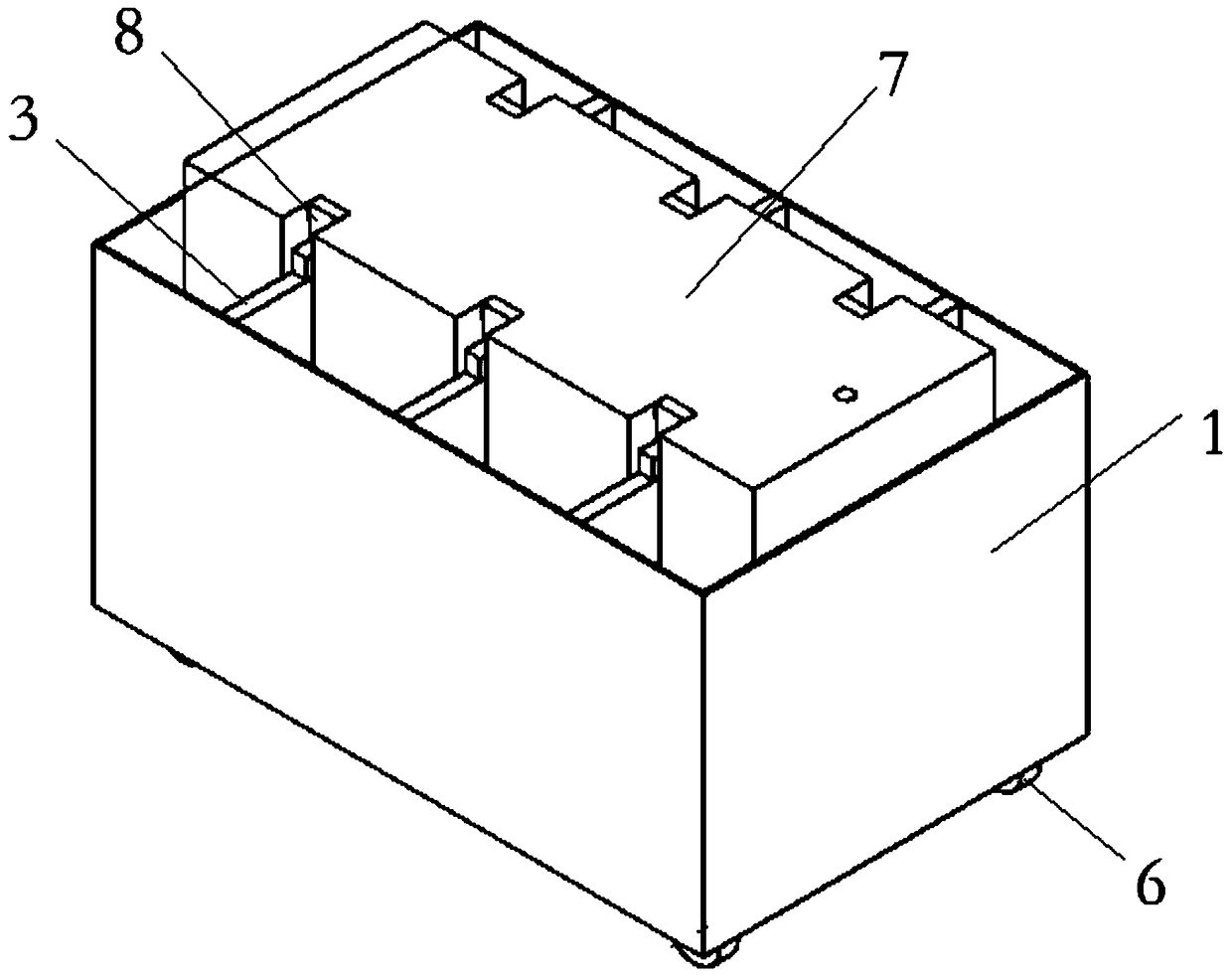

[0034] First, place the molded sand mold 7 on the push robot. At this time, the turning mechanism clamps the clamping part 2 in the empty sand box trolley. The empty sand box trolley is as follows: figure 1 and figure 2 As shown, under the effect of the box turning mechanism, the sand box trolley turns sideways, and the box opening of the box body 6 is aligned with the push robot; when the sand mold 7 is pushed into the box body 6 under the action of the push robot, The sand box trolley is reversed and restored, and the installation groove 8 on the sand mold 7 is matched with the fixed inclined rib 3 of the sand mold. Under the action of the pushing robot and the gravity of the sand mold 7 itself, the empty sand mold 7 is locked on the sand box trolley , that is, the sand mold 7 is installed in the box body 6 in a manner similar to a wedge through the cooperation of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com