A light-emitting diode epitaxial wafer and its manufacturing method

A technology of light emitting diodes and epitaxial wafers, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency of LEDs, and achieve the effects of improving luminous efficiency, improving secondary light emitting efficiency, and increasing the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

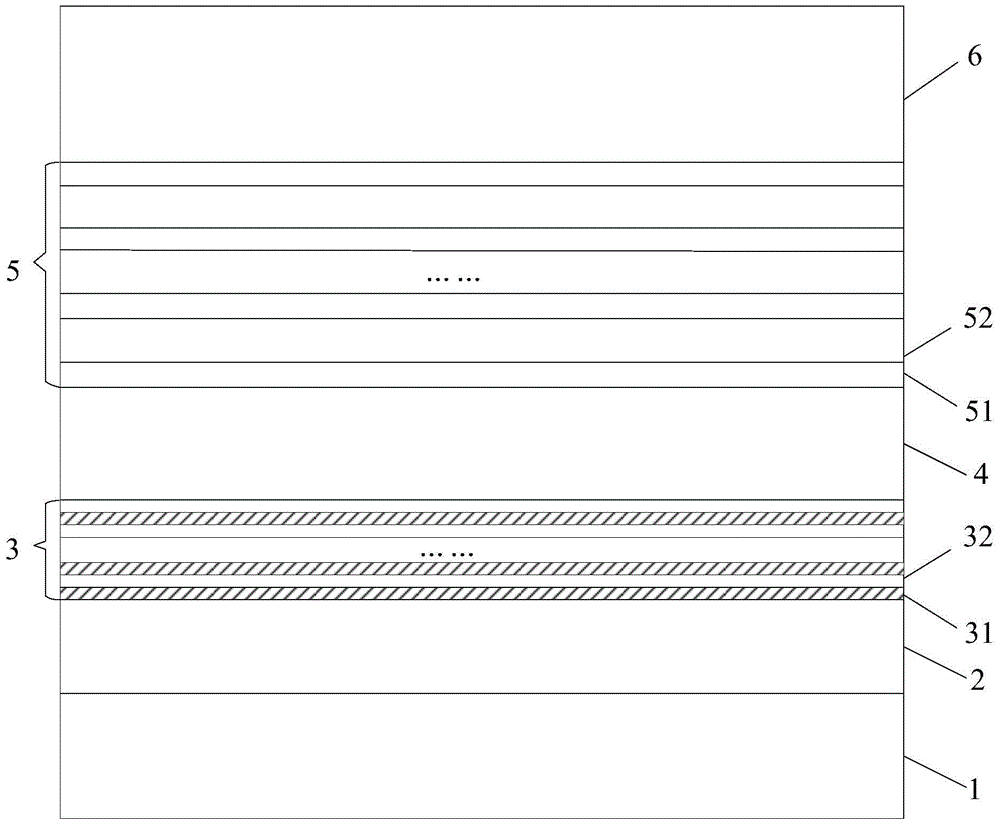

[0025] An embodiment of the present invention provides an LED epitaxial wafer, see figure 1 , the epitaxial wafer includes a sapphire substrate 1, and an undoped GaN layer 2, a superlattice GaN layer 3, an N-type GaN layer 4, an active layer 5, and a P-type GaN layer 6 sequentially stacked on the sapphire substrate 1 .

[0026] In this embodiment, the growth temperature of the superlattice GaN layer 3 is 750-1050° C., and the superlattice GaN layer 3 includes alternately grown first GaN layers 31 (indicated by hatching) and second GaN layers 32, the first The GaN layer 31 is grown in a 3D (three-dimensional) mode, and the second GaN layer 32 is grown in a 2D (two-dimensional) mode. The active layer 5 is an alternately grown InGaN layer 51 and a GaN layer 52 .

[0027] Specifically, the Ga content of the first GaN layer 31 may be 1 / 3-1 / 2 of the Ga content of the second GaN layer 32 .

[0028] Optionally, the total number of layers of the first GaN layer 31 and the second GaN...

Embodiment 2

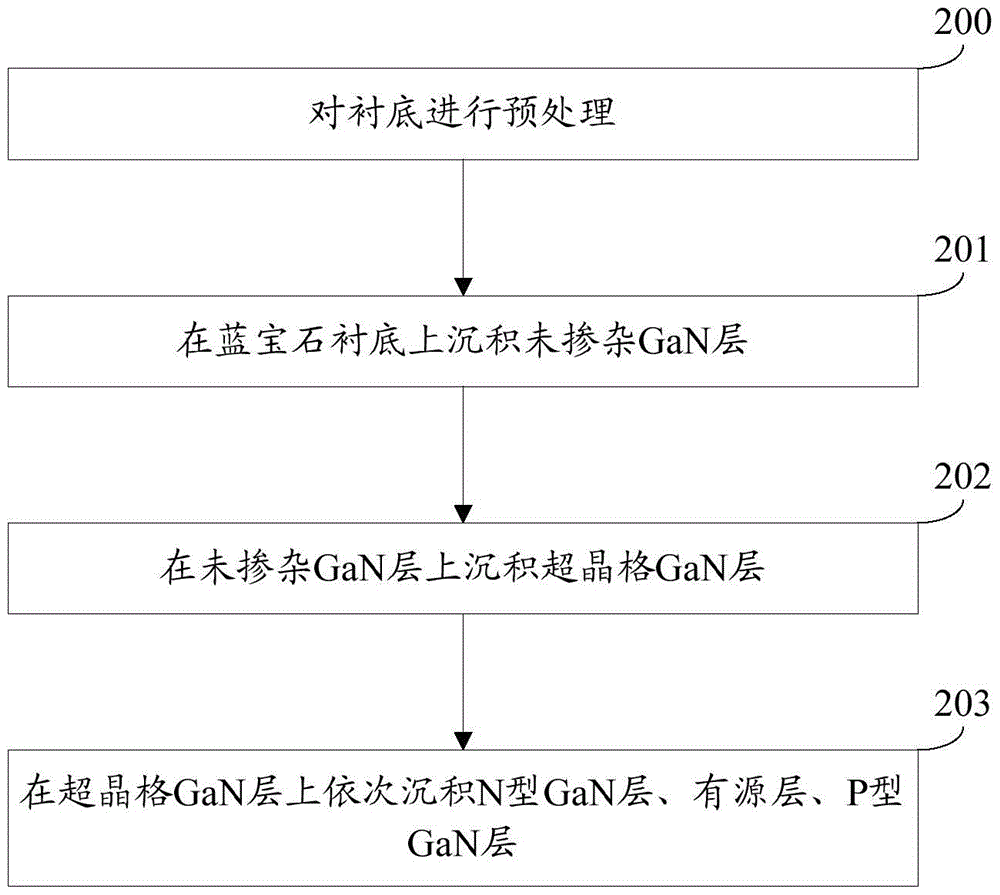

[0034] An embodiment of the present invention provides a method for manufacturing an LED epitaxial wafer, which is suitable for manufacturing the LED epitaxial wafer provided in Embodiment 1, see figure 2 , the method includes:

[0035] Step 200: pretreating the sapphire substrate.

[0036] Specifically, this step 200 may include:

[0037] Put the sapphire substrate into a MOCVD (Metal Organic Chemical Vapor Deposition, metal organic compound chemical vapor deposition) system, and heat-treat at high temperature for 10-15 minutes.

[0038] For example, in an MOCVD system, a sapphire substrate is treated at a temperature of 1100°C in a pure hydrogen atmosphere for 15 minutes.

[0039] Step 201: Deposit an undoped GaN layer on a sapphire substrate.

[0040] Specifically, this step 201 may include:

[0041] 3 μm GaN was grown at 1000°C.

[0042] Optionally, before step 201, the method may also include:

[0043] 20nm GaN was grown at 600°C.

[0044] Step 202: Deposit a supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com