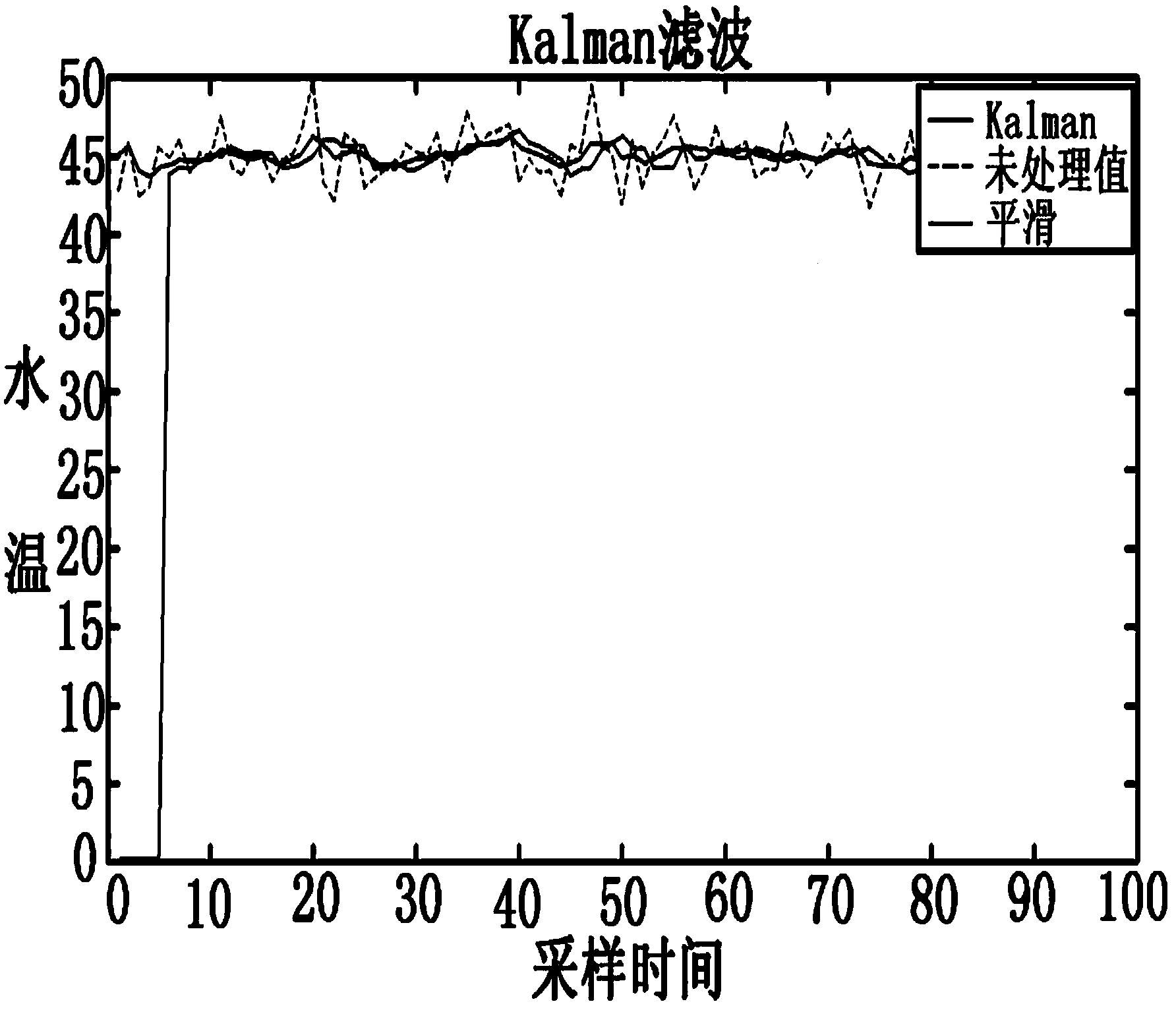

Verification table temperature measuring method based on Kalman filtering

A technology of covariance and noise covariance, which is applied in the field of temperature measurement of the test bench based on Kalman filtering, to achieve the effect of improving accuracy, good smoothness, and improving anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A kind of method for temperature measurement of test platform based on Kalman filter, it is characterized in that, its steps are:

[0015] (1) Initialize the parameters of the Kalman filter, including the influence on the convergence speed, the covariance of dynamic noise (that is, the covariance of the estimated value) Q, the noise covariance R of the process and measurement, etc.;

[0016] (2) Predict the value at the current moment according to the noise value and the optimal value of the previous state, and obtain the predicted current moment noise covariance p10 (p10=p00+Q, p00 is the predicted value at the beginning of the kalman function covariance) and the state estimated value x10 at the current moment (x10=x00, x00 is the optimal value set at the initial moment of kalman filtering), and calculate the Kalman gain Kg according to the predicted value, the calculation formula is kg=p10 / (p10+R);

[0017] (3) Add the new information sequence e, e=z-x10; where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com