Convenience calibration and autonomous control method for digital frequency conversion controller special for industrial metering pump

A digital frequency conversion and autonomous control technology, applied in pump control, machine/engine, liquid variable capacity machinery, etc., can solve the problems of energy consumption, cost increase, inconvenience of manual operation, etc., to reduce devices and simplify operation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

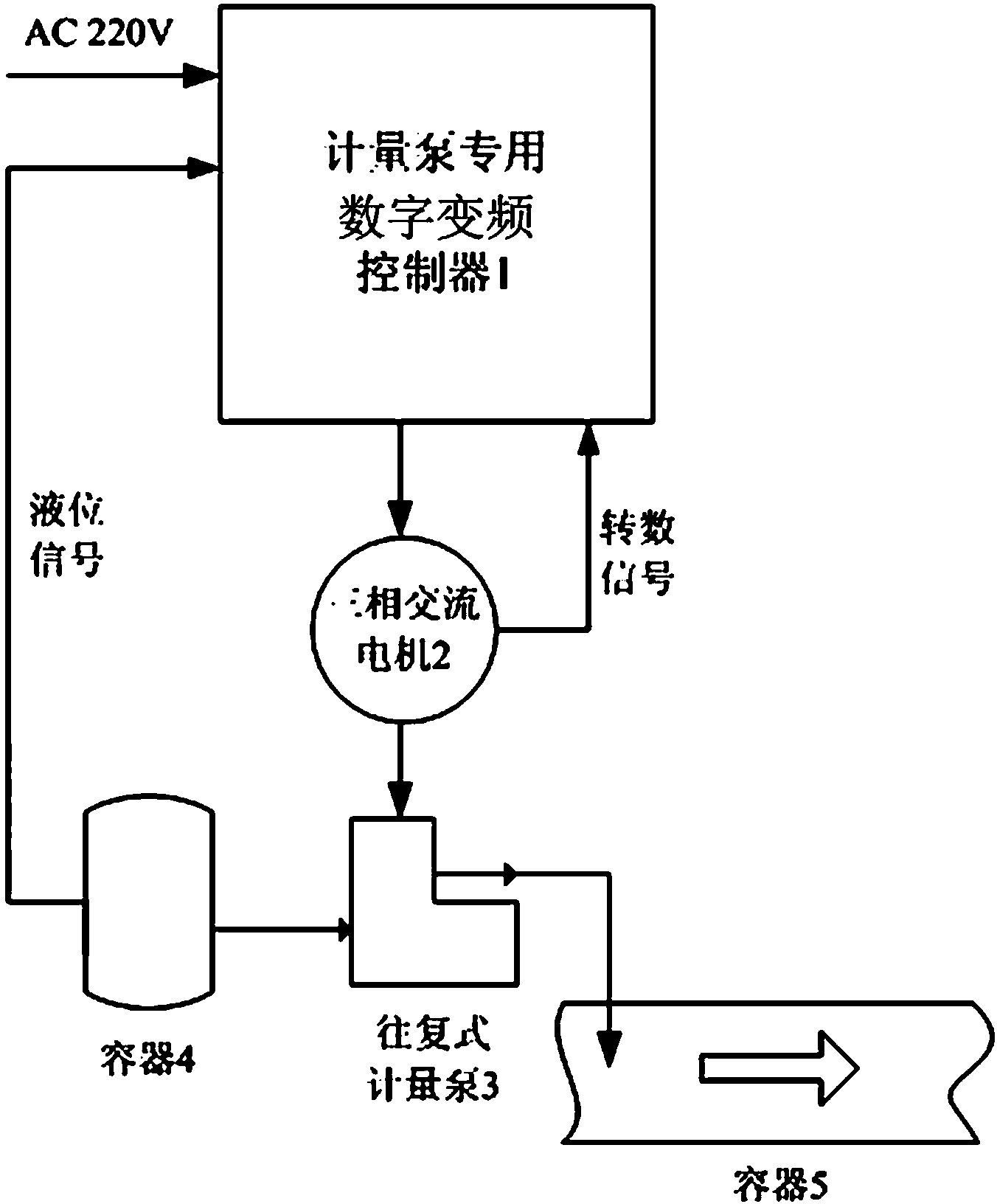

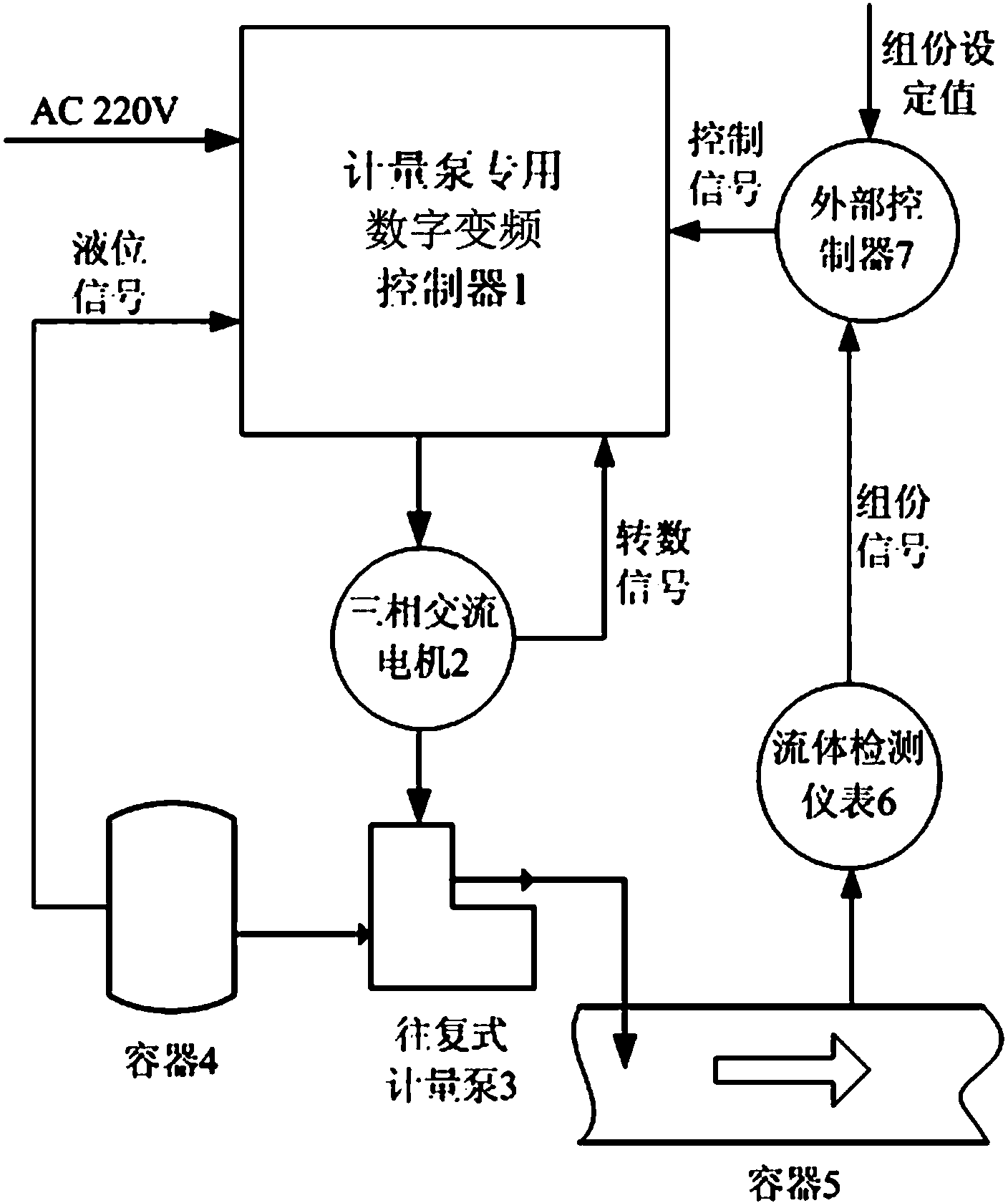

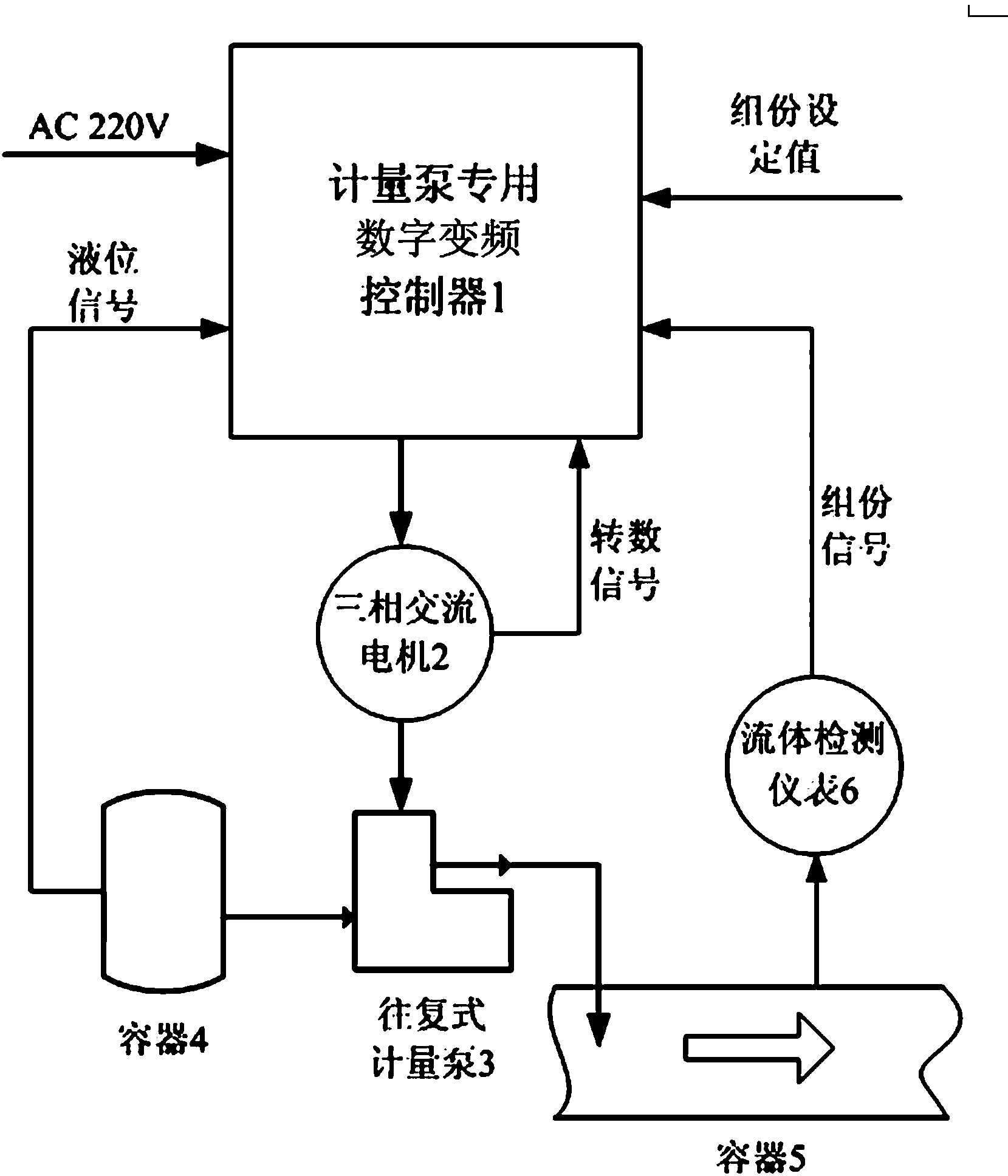

[0050] The present invention will be further described below in conjunction with accompanying drawing.

[0051] Convenient calibration of digital frequency conversion controllers for industrial metering pumps.

[0052] Existing digital frequency conversion controllers dedicated to metering pumps are usually based on the volume change of a single stroke (stroke displacement for short) (L) and transmission ratio To calculate the number of revolutions of the motor required for each liter of fluid output by the metering pump , where the parameter N is a key parameter for calculating instantaneous flow, current flow and cumulative flow. because

[0053] (L) (1)

[0054] therefore,

[0055] (2)

[0056] while the gear ratio It is fixed for a specific metering pump, It is the theoretical parameter given by the manufacturer when leaving the factory. In this way, when the actual operating point conditions (three-phase AC frequency Pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com