Method for large-area deposition of coating and surface modification by cathodic plasma electrolysis

A cathode plasma and surface modification technology, applied in the direction of electrolytic inorganic material coating, etc., to achieve the effect of simple equipment, easy operation and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

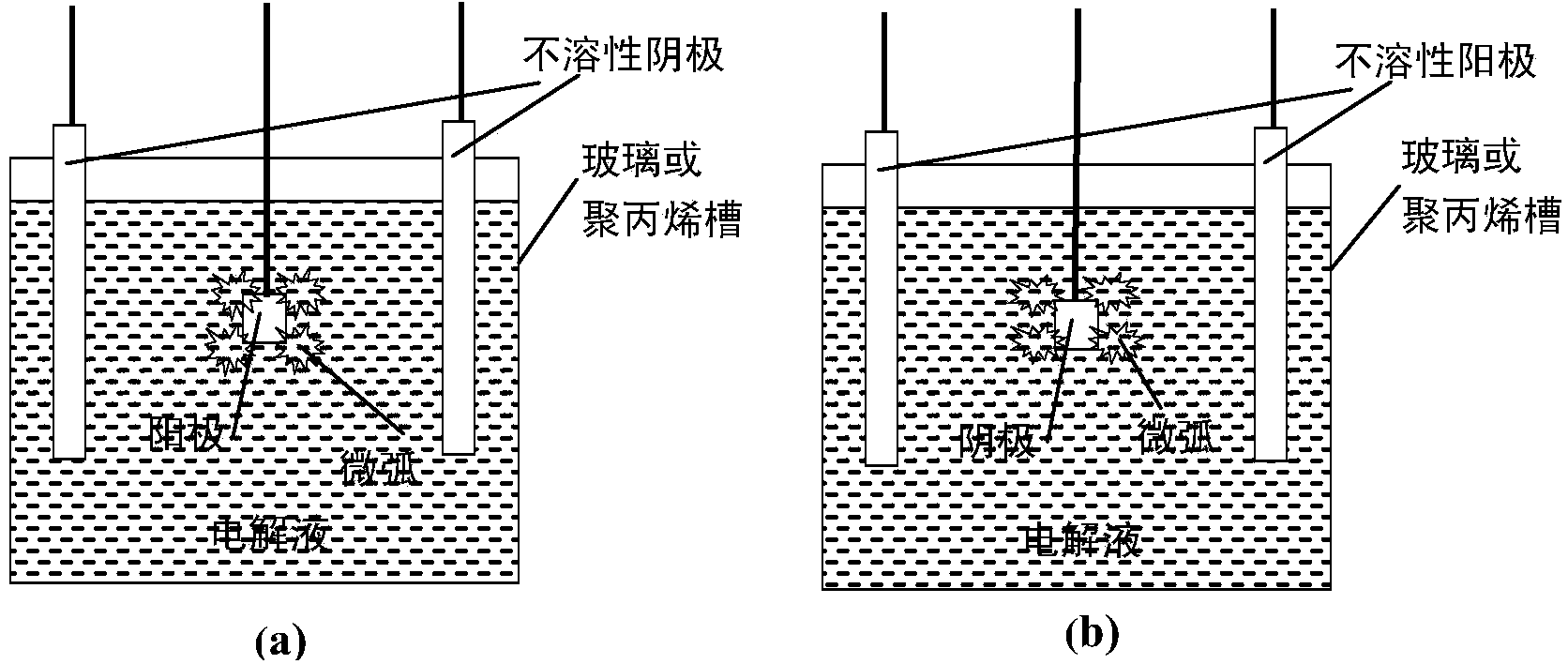

[0018] use figure 1 (b) The general electrolytic cell structure shown. With 0.5M Al(NO 3 ) 3 The aqueous solution is used as the basic electrolyte, and 10g / L of polyvinyl alcohol is added. 1Cr18Ni9Ti stainless steel (50×50×2mm in size) is used as the cathode, and a DC power supply is used. The electrolysis voltage is always controlled at a voltage higher than the arc starting voltage of 25V. 30 minutes of electrolysis can deposit Al with a thickness of 200 microns 2 o 3 coating.

Embodiment 2

[0020] use figure 1 (b) The general electrolytic cell structure shown. With 0.5M Zr(NO 3 ) 4 +0.04M Y(NO 3 ) 3 +0.0002M H 2 PtCl 6 The aqueous solution is used as the basic electrolyte, and then 10g / L of polyethylene glycol is added, and the nickel-based superalloy (the size is 50×50×2mm) is used as the cathode, and a pulse power supply is used with a frequency of 600Hz and a duty cycle of 60%. The voltage is always controlled at a voltage 25V higher than the arcing voltage. A thermal barrier coating of YSZ (yttria stabilized zirconia) dispersed Pt particles with a thickness of 250 microns can be deposited by electrolysis for 40 minutes.

Embodiment 3

[0022] use figure 1 (b) The general electrolytic cell structure shown. Use 80g / l glycerin aqueous solution as the basic electrolyte, then add 10g / L polyethylene oxide, use a 50×50×2mm low-carbon steel plate as the cathode, use a pulse power supply, the frequency is 200Hz, the duty ratio is 50%, the electrolysis voltage Always controlled at a voltage 50V higher than the arcing voltage, after 30 minutes of cathodic plasma electrolysis, a carburized coating with a thickness of about 20 microns was formed on the surface of the steel plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com