Rosmarinus officinalis L. fermentation broth extract as well as preparation method and application thereof

A technology of rosemary and extract, which is applied in the field of tobacco additives, to achieve the effects of simple production process, large-scale industrial production, standardization and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

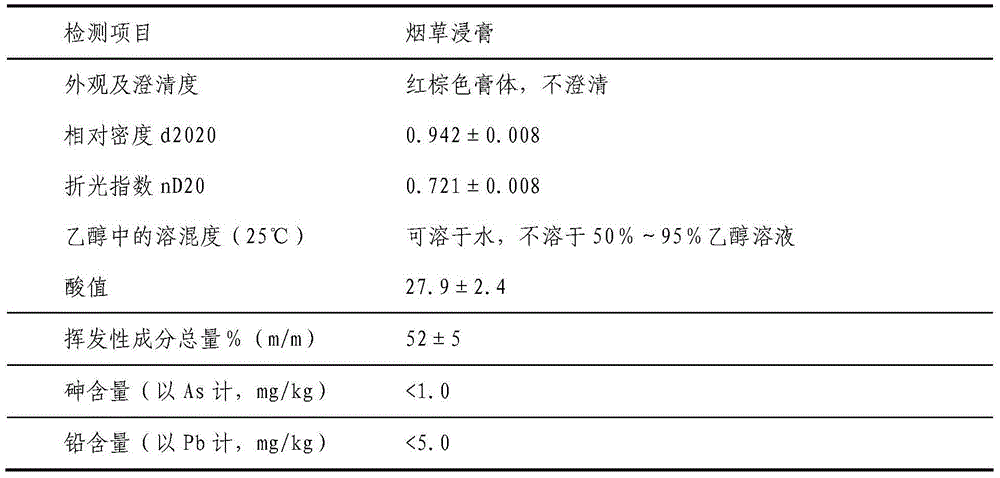

Image

Examples

Embodiment 1

[0028] 1. Media and culture conditions

[0029] The Saccharomyces longans CGMCC 6645 used in the experiment was inoculated in 50 mL of YPD liquid medium, and cultured at 28°C and 160 r / min for 24 hours to obtain activated liquid strains.

[0030] 2. Preparation of Rosemary Samples

[0031] After the rosemary is fully dried, crush it and pass through a 40-mesh sieve. Weigh 20 g of rosemary powder, add 400 mL of distilled water (20 volume times), sterilize, and set aside.

[0032] 3. Aroma-producing yeast fermentation treatment of rosemary

[0033] Inoculate 8 mL of the activated Saccharomyces spp. bacterium solution prepared in 1 into the rosemary sample prepared in 2 (the inoculum size is 2%), culture at 28°C and 160 r / min for 24 hours with shaking, and use it for the next experiment .

[0034] 4. Extraction of spice additives

[0035] After filtering the above fermented liquid, centrifuge it at 8000r / min for 10 minutes, take the supernatant, concentrate it under reduced ...

Embodiment 2

[0048] Repeat Example 1, with the following differences:

[0049] The culture conditions for the activation of the strain CGMCC 6645 are 28°C, 160r / min shaking culture, and the culture time is 24 hours; the rosemary is crushed and 22 times distilled water is added to sterilize; the activated bacteria solution is inoculated in the rosemary The inoculum amount of the material is 2.5%; the fermentation and cultivation time after inoculation is 24 hours; the supernatant of the fermentation liquid is concentrated under reduced pressure at a temperature of 55° C.; the prepared spice additive is evenly sprayed on the shredded tobacco, and the addition amount is 12 g / box.

[0050] The results of flavoring and smoking test show that the flavor additive can harmonize with the aroma of cigarettes, improve the quality of aroma, increase the amount of aroma, improve the aftertaste, cover up the miscellaneous smell, and have a fresh and special aroma.

Embodiment 3

[0052] Repeat Example 1, with the following differences:

[0053] The culture conditions for the activation of the strain CGMCC 6645 are 30°C, 180r / min shaking culture, and the culture time is 12 hours; the rosemary is crushed and 15 times of distilled water is added to sterilize; the activated bacteria solution is inoculated in the rosemary The inoculum amount of the material is 1.5%; the fermentation and cultivation time after inoculation is 12 hours; the concentration temperature of the supernatant of the fermentation broth under reduced pressure is 45° C.; the prepared spice additive is evenly sprayed on the shredded tobacco, and the addition amount is 8 g / box.

[0054] The results of flavoring and smoking test show that the flavor additive can harmonize with the aroma of cigarettes, improve the quality of aroma, increase the amount of aroma, improve the aftertaste, cover up the miscellaneous smell, and have a fresh and special aroma.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com