Circulating reflux device for oil-containing emulsified liquid

A technology of circulating backflow and emulsification, which is applied in the fields of grease/oily substance/float removal device, liquid separation, osmotic/dialysis water/sewage treatment, etc. It can solve the problems of wasting electric energy, increasing enterprise cost, blocking pipes and equipment, etc. , to save operation and processing time, improve production efficiency, and prevent accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

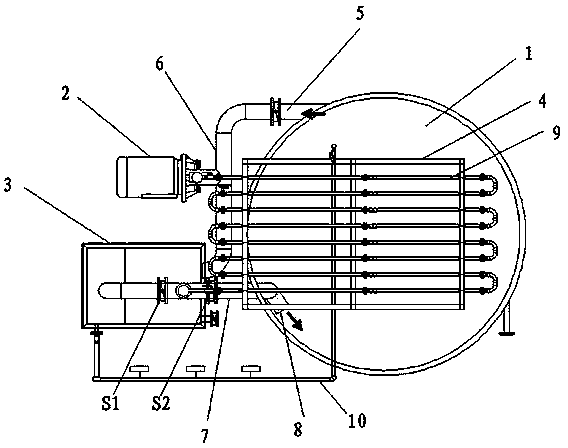

[0017] Example 1: Such as figure 1 A kind of circulation reflux device for oil-containing emulsion shown, described circulation reflux device comprises ultrafiltration circulation tank 1, ultrafiltration circulation pump 2, ultrafiltration cleaning tank 3 and ultrafiltration membrane pipe rack 4, described The ultrafiltration circulation tank 1 is a cylindrical shell structure, and the bottom of the ultrafiltration circulation tank 1 is provided with a circulation liquid outlet pipe 5 connected to the ultrafiltration membrane pipe frame 4 by the ultrafiltration circulation pump 2, and the The ultrafiltration membrane pipe rack 4 is a one-way transmission pipeline, and the tail of the ultrafiltration membrane pipe rack 4 is provided with two shunt branch pipes connected to the ultrafiltration cleaning tank 3 and the circulation inlet pipe 7 respectively, and the circulation inlet The liquid pipe 7 is connected to the upper part of the ultrafiltration circulation tank 1, and t...

Embodiment 2

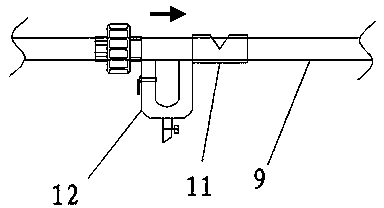

[0018] Example 2: Such as figure 1 with 2 As shown, the ultrafiltration membrane pipe rack 4 comprises a plurality of ultrafiltration tubes 9 containing a filter membrane inside, and the ultrafiltration membrane pipe rack 4 is connected into an integral structure by connecting elbows for a plurality of ultrafiltration membrane pipe racks; The filter membrane structure 11 of the ultrafiltration tube 9 is arranged in the middle part of the ultrafiltration tube 9; the pipeline of the liquid inlet end of the filter membrane structure 11 is provided with a U-shaped oil outlet pipe 12; Emulsified oil, the emulsified oil accumulated at the front end of the filter membrane structure 11 is discharged through the U-shaped oil outlet pipe 12, which is easy to operate, does not affect the normal operation of the system, and improves the production efficiency of the enterprise.

Embodiment 3

[0019] Example 3: Such as figure 1 As shown, a switch ball valve S1 is provided on the connecting pipeline between the ultrafiltration membrane pipe rack 4 and the ultrafiltration cleaning tank 3, and a switch ball valve S2 is arranged between the ultrafiltration membrane pipe rack 4 and the circulating liquid inlet pipe 7; Ball valves S1 and S2 can select the working mode of the device. After the overall degreasing is completed, open the ball valve S1 on the ultrafiltration cleaning tank, close the ball valve S2 on the circulation inlet pipe, and discharge the processed liquid into the ultrafiltration cleaning tank 3 , the cycle degreasing work is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com