A continuous unloading and packaging system for glass substrates

A glass substrate and packaging system technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problem of inability to realize automatic, mechanized transmission and precise positioning of spacer paper, inability to meet high-speed paper laying requirements, and inability to achieve bidirectional paper laying requirements. and other problems, to achieve the effect of simple structure and process action, high reliability of paper extraction, and easy safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

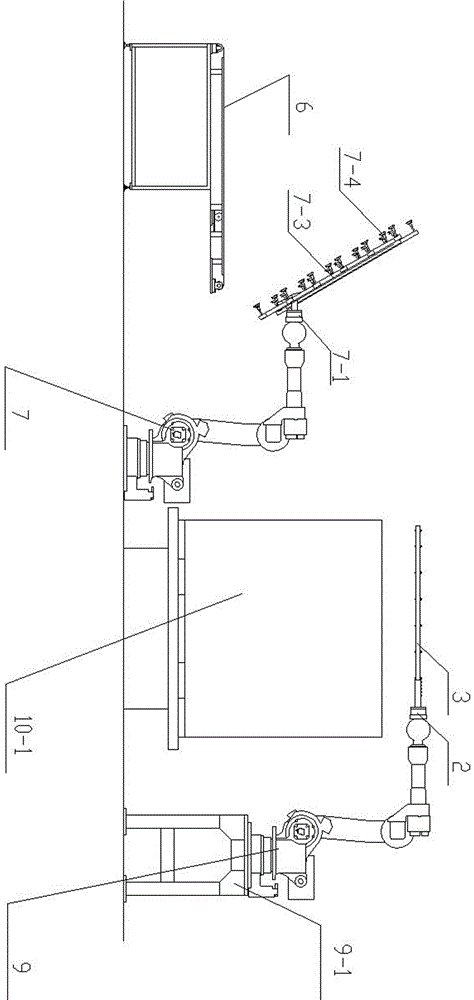

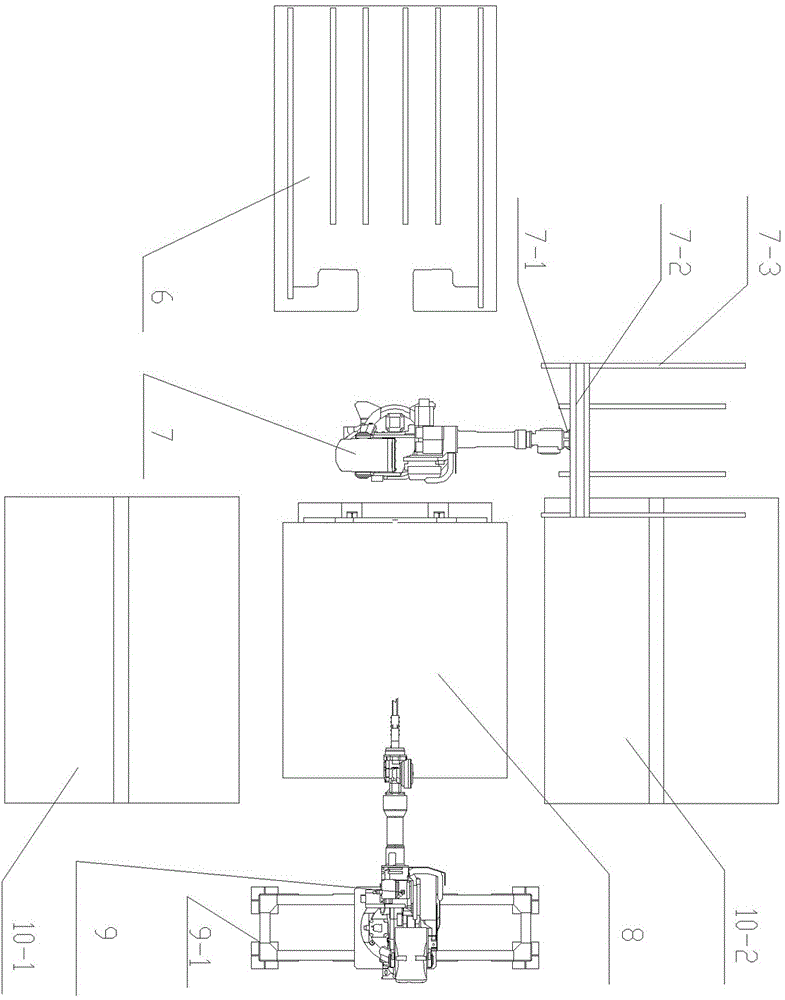

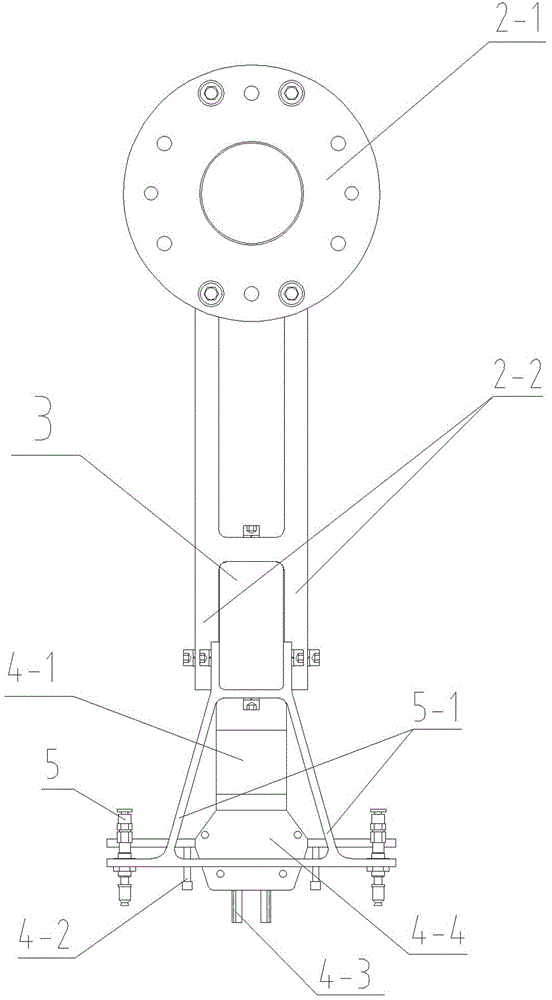

[0022] see Figure 1-2 , a continuous unloading and packaging system for glass substrates, used to put the glass substrates on the unloading conveyor belt 6 into the A-frame, and lay spacer paper between the glass substrates to complete the packaging process, the important Yes: the system structure includes: control and management circuit, unloading robot 7, paper storage table 8, and bridge support frame 9-1 erected at the end of the lower conveyor belt 6 and along the transmission direction of the lower conveyor belt 6. The paper-laying robot 9 is also provided with left and right A-frames 10-1 and 10-2 with a turntable base on both sides of the paper storage table 8. With the help of the control of the control management circuit, the unloading robot 7 and the laying robot The paper robot 9 cooperates to form an assembly line packaging system structure in which the lower sheet of the glass substrate is placed on the left / right A-frame 10-1 and 10-2 in turn, and spacer paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com