Microfluidic device for fluid detection and method for making the same

A technology for microfluidic devices and fluid detection, which is used in laboratory containers, chemical instruments and methods, processes for producing decorative surface effects, etc. It is difficult to process small-sized microstructures and other problems to achieve the effect of improving efficiency and enhancing etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

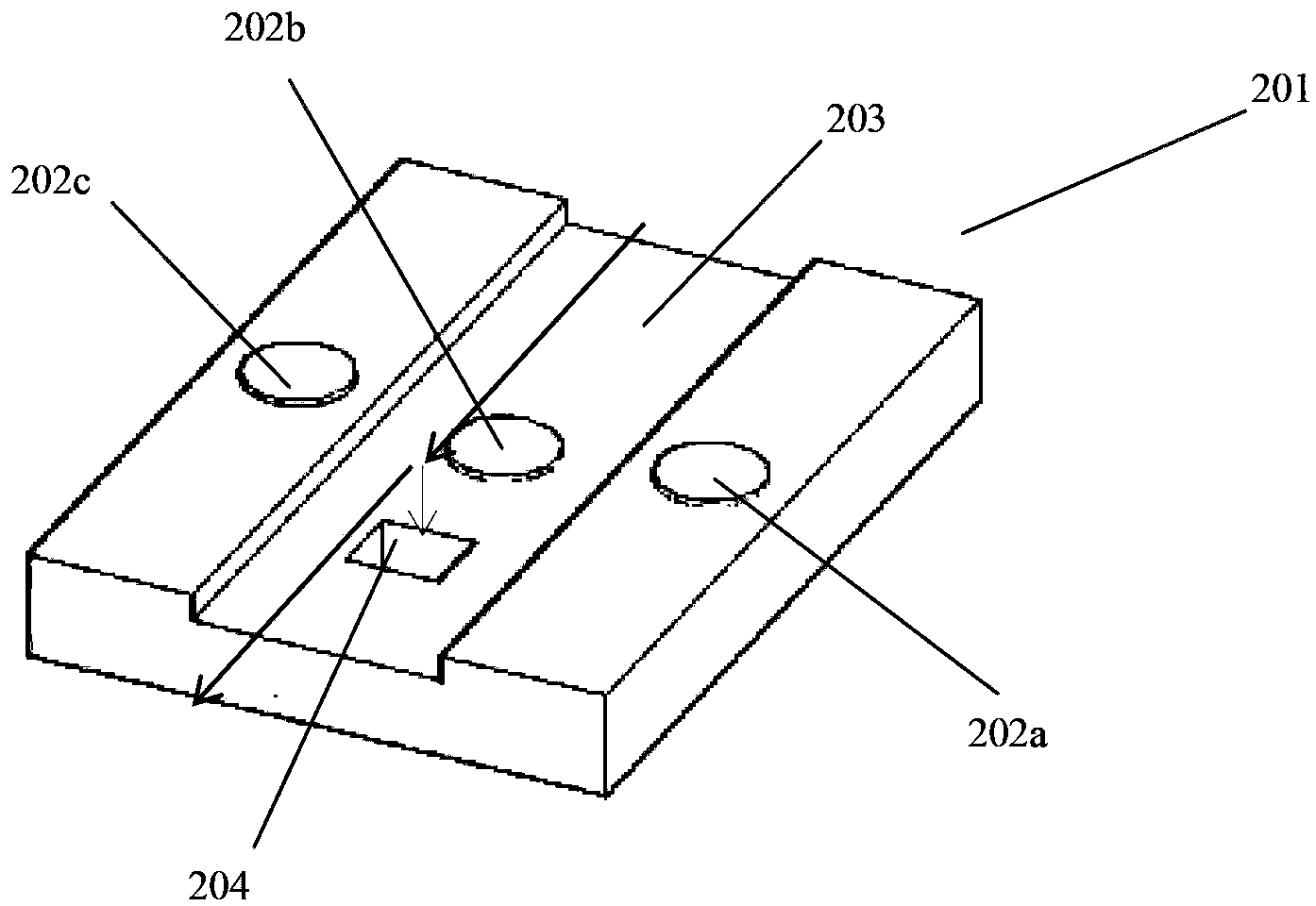

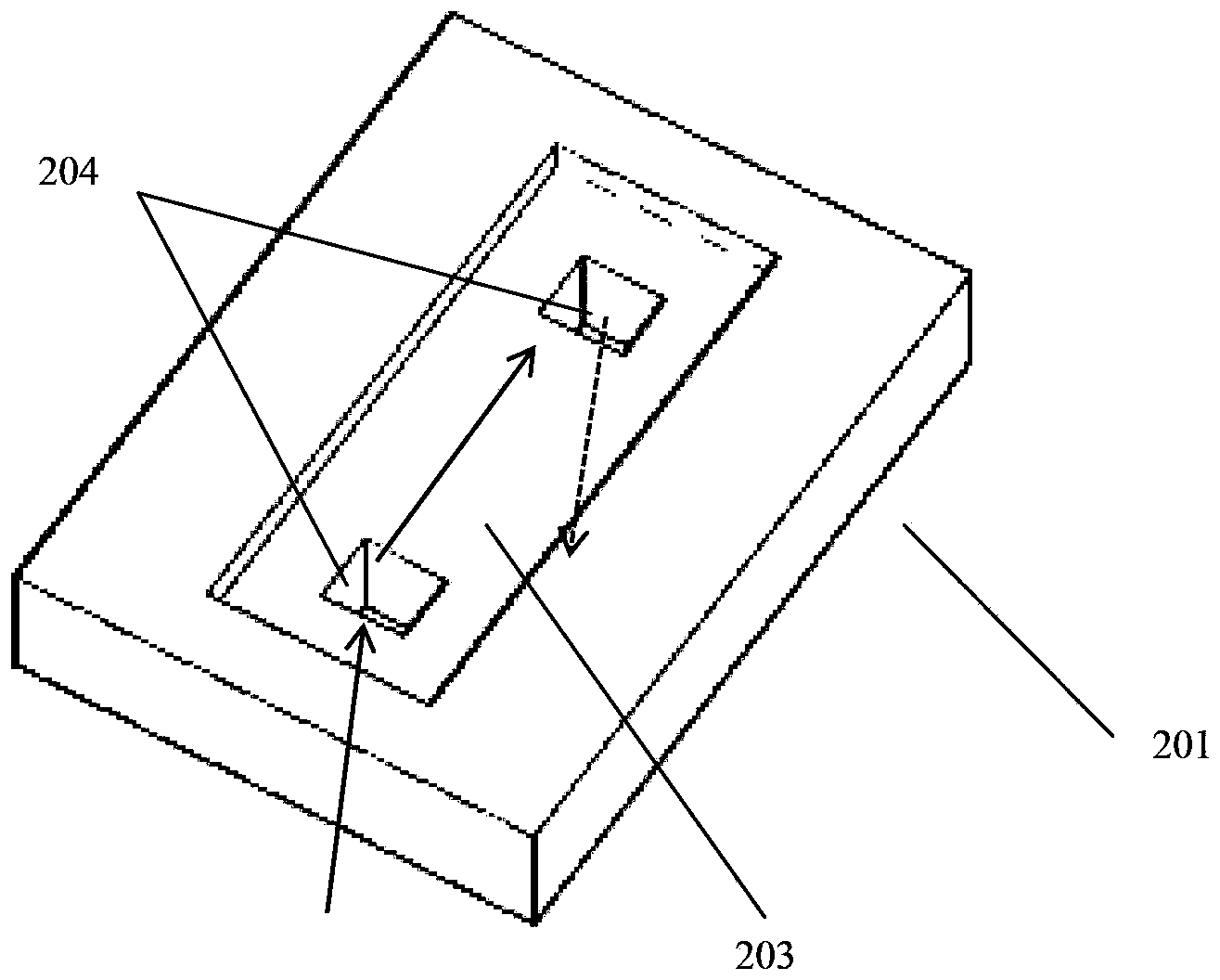

[0030] refer to Figure 2a and image 3 , is a structural schematic diagram of a preferred embodiment of the device structure of the present invention, the device 201 includes a substrate 208 and a third precipitation material 206 and a fourth precipitation material 207 deposited on the substrate sequentially from top to bottom, and the microfluidic The device is provided with three detection units 202a, 202b, 202c. One side of the microfluidic device has a groove 203. The groove 203 is a through-groove structure, which runs through the upper and lower ends of the device 201, and is provided in the groove. A microfluidic channel 204 runs through the microfluidic device. Among them, the fluid flow mode is as follows Figure 2a In the direction indicated by the middle arrow, the fluid flows into the groove 203 , and when pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com