Method for producing probiotic peptides by using two-step solid-state fermentation of peanut meal

A technology of solid-state fermentation and peanut meal, which is applied in the field of animal feed and bioengineering, can solve problems such as limited content of beneficial metabolites, difficulty in functioning of bacillus and neutral protease, inconsistent demands, etc., to enhance disease prevention and resistance, The effect of highlighting substantive features and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

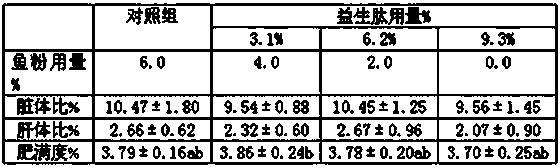

Image

Examples

Embodiment 1

[0035]Use peanut meal as raw material, mix it with tap water at a material-to-water ratio of 1:0.8, and then sterilize at 121°C for 20 minutes. After sterilization, insert Aspergillus niger (CGMCC No.9183) spores at 2% (v / w) of the peanut meal weight After mixing evenly, culture at 28°C~32°C for 28 hours, turning over every 4 hours; after the cultivation is completed, mix 3 batches, and insert 10% (v / w) Pediococcus pentosaceae (CGMCC No. .9182), mixed evenly and anaerobically fermented at 37°C~46°C for 42 hours, dried and pulverized at 60°C after the fermentation was completed, to obtain prebiotic peptides. The peptide content of the probiotic peptide reaches 28.4%, the lactic acid content reaches 8.8%, and the number of viable lactic acid bacteria reaches 1.2×10 9 CFU / g, acid protease reaches 228U / g.

Embodiment 2

[0037] Use peanut meal as raw material, mix it with tap water at a material-to-water ratio of 1:0.8, and then sterilize at 121°C for 20 minutes. After sterilization, insert Aspergillus niger (CGMCC No.9183) spores at 2% (v / w) of the peanut meal weight After mixing evenly, culture at 28°C~32°C for 26 hours, turn over every 4 hours; after the cultivation, mix 3 batches, and insert 10% (v / w) Pediococcus pentosaceae (CGMCC No. .9182), mixed evenly and anaerobically fermented at 37°C~46°C for 36 hours, dried and pulverized at 60°C after the fermentation was completed, to obtain prebiotic peptides. The peptide content of probiotic peptides reaches 26.2%, the lactic acid content reaches 8.3%, and the number of live lactic acid bacteria reaches 1.0×10 9 CFU / g, acid protease reaches 212U / g.

Embodiment 3

[0039] Use peanut meal as raw material, mix it with tap water according to the ratio of material to water 1:1.1, sterilize at 120°C for 15 minutes, and insert spores of Aspergillus niger (CGMCC No.9183) at 2% (v / w) of the weight of peanut meal after sterilization After mixing evenly, culture at 28°C~32°C for 28 hours, turning over every 4 hours; after the cultivation is completed, mix 3 batches, and insert 10% (v / w) Pediococcus pentosaceae (CGMCC No. .9182), mixed evenly and anaerobically fermented at 37°C~46°C for 36 hours, dried and pulverized at 60°C after the fermentation was completed, to obtain prebiotic peptides. The peptide content of probiotic peptides reaches 25.4%, the lactic acid content reaches 8.2%, and the number of live lactic acid bacteria reaches 1.0×10 9 CFU / g, acid protease reaches 201U / g.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com