High voltage direct current circuit breaker topology circuit

A topological circuit and high-voltage direct current technology, applied in the direction of direct current network circuit devices, circuit devices, electrical components, etc., can solve the problems of poor economy, large loss, and breaking time that cannot meet the multi-terminal flexible direct current transmission system, etc., and achieve low equipment cost, The effect of prolonging the service life and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

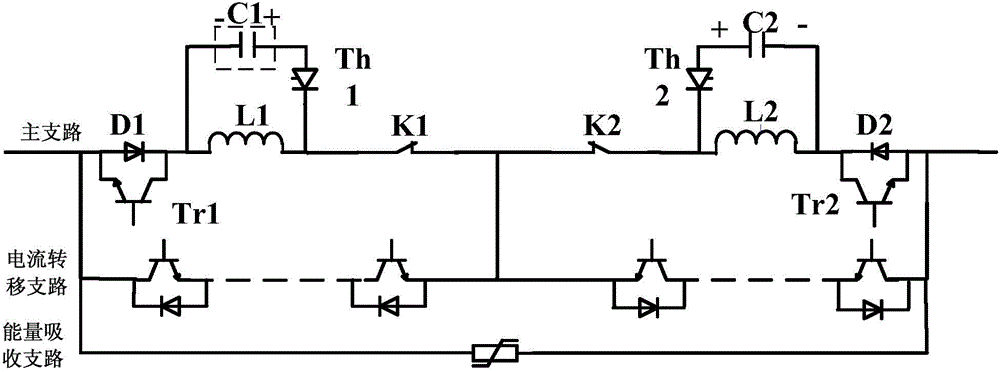

[0030] Such as figure 1 , the topological circuit of the high-voltage DC circuit breaker includes a main branch, a current transfer branch and an energy absorption branch; the main branch, the current transfer branch and the energy absorption branch are connected in parallel.

[0031] 1) The main branch circuit includes a first main branch circuit and a second main branch circuit connected in series; the first main branch circuit includes a fast mechanical switch K1, an LC discharge circuit and power electronic devices;

[0032] The power electronic device uses a transistor Tr1 with an anti-parallel diode. The LC discharge circuit includes an inductor L1, a capacitor C1 and a thyristor Th1. One end of the inductor L1 is connected to the cathode of the anti-parallel diode D1, and the other end is connected to a fast mechanical switch K1, capacitor C1 and thyristor Th1. After being connected in series, it is connected in parallel at both ends of the inductor L1;

[0033] The se...

Embodiment 2

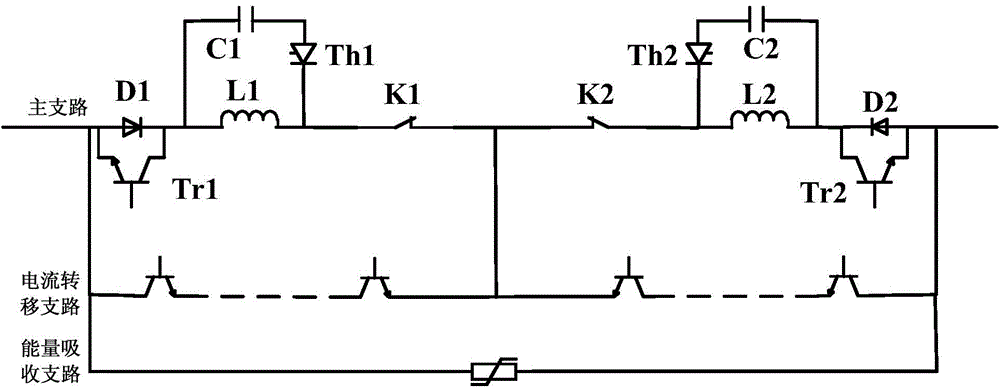

[0044] Such as figure 2 , the topological circuit of the high-voltage DC circuit breaker includes a main branch, a current transfer branch and an energy absorption branch; the main branch, the current transfer branch and the energy absorption branch are connected in parallel.

[0045] 1) The main branch circuit includes a first main branch circuit and a second main branch circuit connected in series; the first main branch circuit includes a fast mechanical switch K1, an LC discharge circuit and power electronic devices;

[0046] The power electronic device uses a transistor Tr1 with an anti-parallel diode. The LC discharge circuit includes an inductor L1, a capacitor C1 and a thyristor. One end of the inductor L1 is connected to the cathode of the anti-parallel diode D1, and the other end is connected to a fast mechanical switch K1. The capacitor C1 is connected in series with the thyristor Th1. Afterwards, it is connected in parallel at both ends of the inductor L1;

[0047...

Embodiment 3

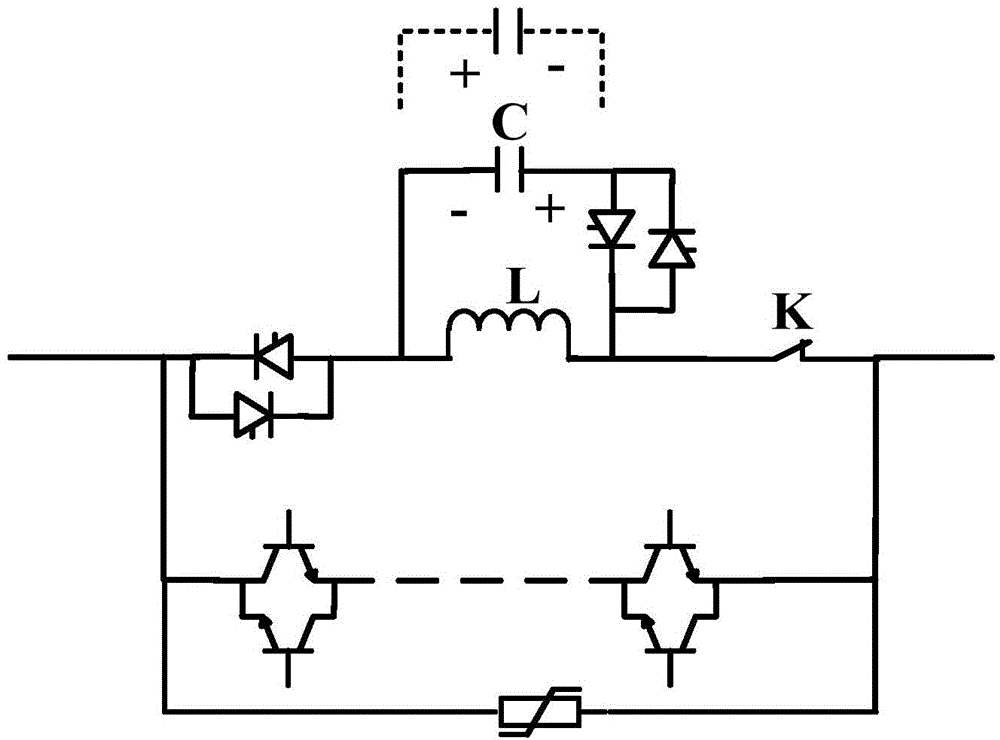

[0052] Such as image 3 , the topological circuit of the high-voltage DC circuit breaker includes a main branch, a current transfer branch and an energy absorption branch; the main branch, the current transfer branch and the energy absorption branch are connected in parallel.

[0053] 1) The main branch includes fast mechanical switch K, LC discharge circuit and power electronic devices; the inherent oscillation period of LC discharge circuit T = 2 π LC ;

[0054] The power electronic device adopts two thyristor anti-parallel structure; LC discharge circuit includes inductor L, capacitor C and two thyristor anti-parallel structure, one end of inductor L1 is connected to two thyristor anti-parallel structure, the other end is connected to fast mechanical switch K, capacitor C and Two thyristor anti-parallel structures are connected in parallel at both ends of the inductor L after being connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com