Battery-electric-vehicle hybrid power system efficiency calculation model and optimization method

A pure electric vehicle and system efficiency technology, applied in the field of efficiency calculation model and optimization of pure electric vehicle composite power supply system, can solve the problems of large demand power, shortening, low energy efficiency, etc., to improve system efficiency, prolong battery life, increase The effect of driving mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

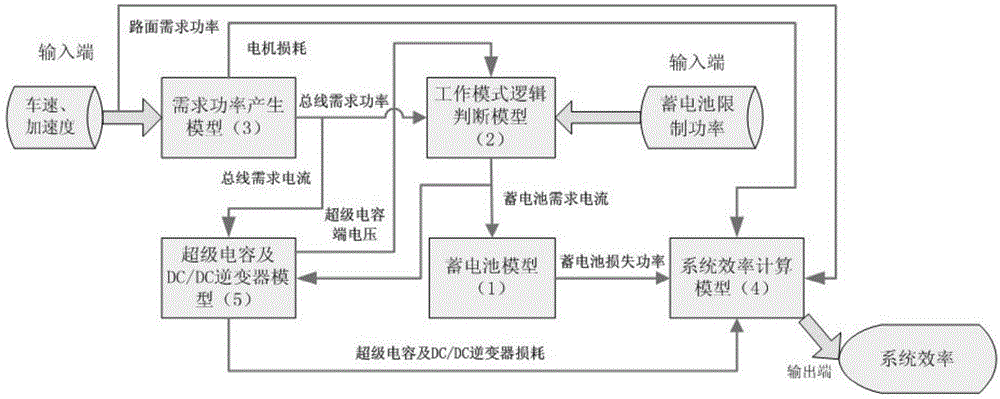

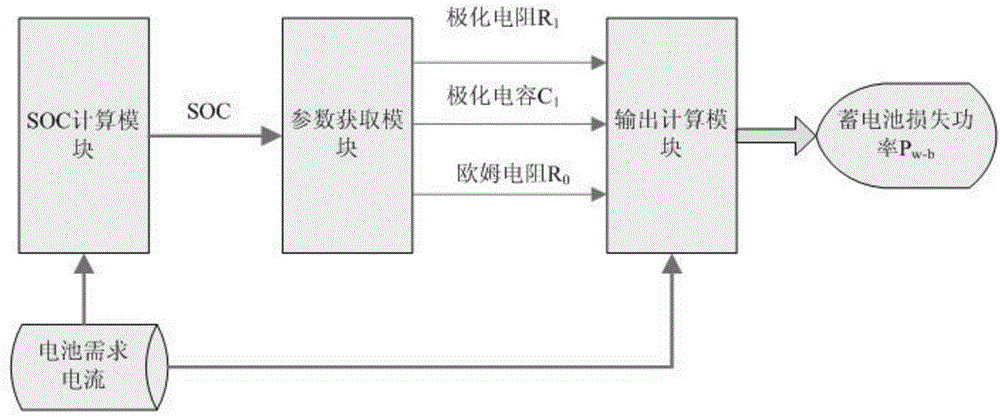

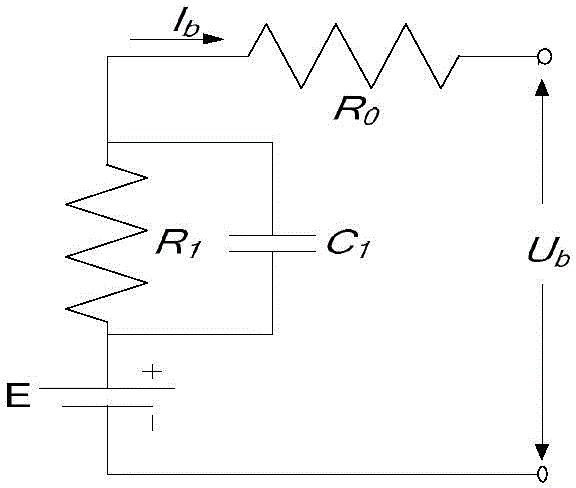

[0040] Such as figure 1 As shown, a pure electric vehicle composite power system efficiency calculation model based on MATLAB, including: battery model 1, working mode logic judgment model 2, demand power generation model 3, system efficiency calculation model 4, super capacitor and DC / DC inverter The battery model 5; the battery model 1 is used to calculate the power loss of the battery under different working conditions; the working mode logic judgment model 2 is used to distribute the power flow of the system; the system demand power model 3 is used to provide road surface The required power is input as the system; the system efficiency calculation model 4 is used to summarize the power consumption of each model of the system to calculate the system efficiency η; the supercapacitor and DC / DC inverter model 5 are used to calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com