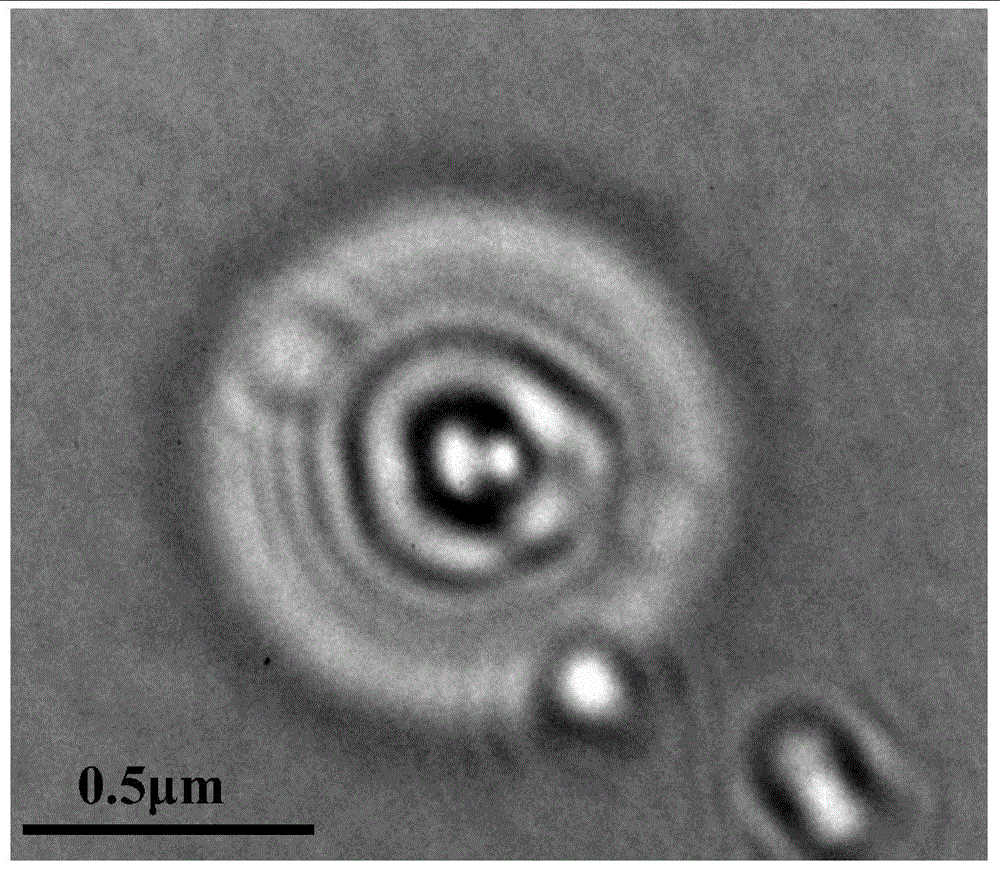

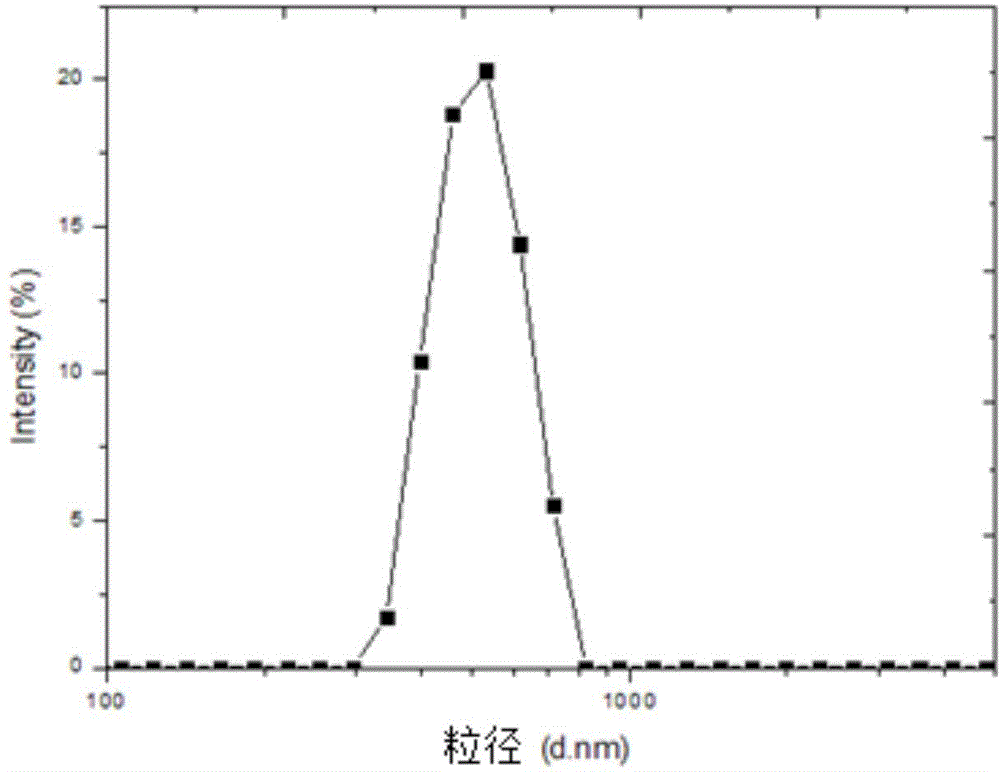

Multilayer hollow casein-based submicrometer composite microcapsule and preparation method thereof

A technology of composite microcapsules and empty cheese, which is applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., can solve the problems such as no public reports, and achieve the effect of strong coating and sustained release, and good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of multilayer hollow casein-based submicron composite microcapsules, specifically comprising the following steps:

[0028] Step 1: Prepare lye with a mass fraction of 2% to 4%. The lye is any one of sodium carbonate aqueous solution, triethanolamine aqueous solution or sodium bicarbonate aqueous solution, and then add casein powder. Casein can be food grade, Industrial grade and refined first grade casein powder can be dissolved in alkaline solution, the mass ratio of casein to lye is 1:10~20, after ultrasonic treatment for 5min~20min, stir and dissolve at 50℃~100℃ 24h~48h, obtain casein solution;

[0029]Step 2: Dissolving amphiphilic copolymer micelles Pluronic F127 or P123 in tetrahydrofuran to form a homogeneous transparent solution, the mass-volume ratio of amphiphilic copolymer micelles to tetrahydrofuran is (9~15)g:(90~180)mL, After stirring for 8-14 hours, add the nanoparticle precursor and sonicate for 25min-80min. The mass-volume ratio of...

Embodiment 1

[0033] Step 1: Prepare 20 g of a weak base solution with a mass fraction of 2%, add 1 g of casein powder therein, ultrasonicate for 5 min, and stir at 50° C. for 24 h to obtain a casein solution;

[0034] Step 2: Dissolve 90 mg of amphiphilic copolymer micelles F127 in 900 μL of tetrahydrofuran to form a homogeneous transparent solution. After stirring for 8 hours, add 85 μL of tetraethyl orthosilicate to it and sonicate for 25 minutes to obtain a mixed solution;

[0035] Step 3: Use a micro-syringe to slowly and uniformly inject the mixed solution obtained in step 2 into the casein solution obtained in step 1 at a speed of 800 rpm under high-speed stirring according to the mass ratio of the mixed solution to the casein solution of 1:20 In a container, the mixture was continuously stirred at 60° C. for 4 days, and the tetrahydrofuran was evaporated to dryness to obtain multilayer hollow casein-based submicron composite microcapsules.

Embodiment 2

[0037] Step 1: Prepare 40 g of a weak base solution with a mass fraction of 4%, add 4 g of casein powder therein, ultrasonicate for 20 min, and stir at 100° C. for 48 h to obtain a casein solution;

[0038] Step 2: Dissolve 150 mg of amphiphilic copolymer micelles F127 in 1800 μL of tetrahydrofuran to form a homogeneous transparent solution. After stirring for 14 hours, add 140 μL of methyl orthosilicate to it and sonicate for 80 minutes to obtain a mixed solution;

[0039] Step 3: Using a micro-syringe, the mass ratio of the mixed solution to the casein solution is 1:10. Slowly and uniformly inject the mixed solution obtained in step 2 into the casein solution obtained in step 1 at a speed of 600 rpm under high-speed stirring. In a liquid container, the mixture was continuously stirred at 80°C for 8 days, and the tetrahydrofuran was evaporated to dryness to obtain multilayer hollow casein-based submicron composite microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com