Method for preparing methyl chloroacetate

A technology of methyl chloroacetate and chloroacetic acid is applied in the field of esterification synthesis technology, which can solve the problems of high process energy consumption, low content of methyl chloroacetate, complicated rectification process, etc., and achieves simple production process and saving methanol consumption. , the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

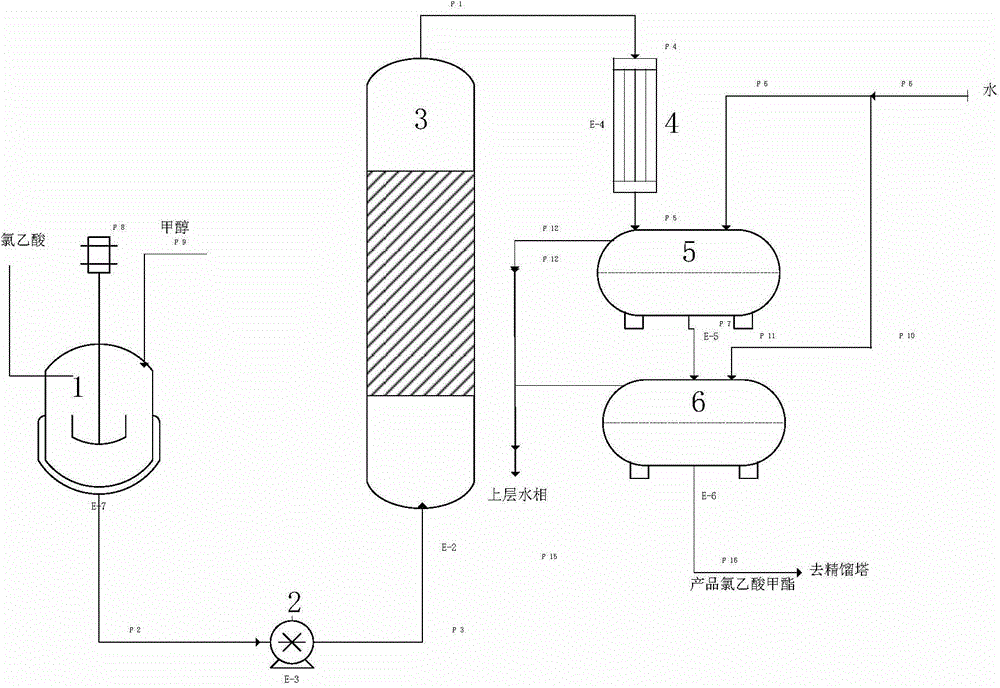

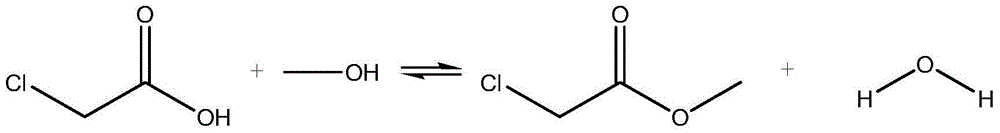

[0030] New method flow chart of the present invention sees figure 1 , chloroacetic acid and methanol are stirred and mixed at room temperature in the raw material tank 1 according to the molar ratio of 1:1, and are injected into the bottom of the fixed-bed reactor 3 through the raw material pump 2, and the catalyst is filled in the fixed-bed reactor, and the loading amount is about 2 / 3 of the reactor volume. The reaction temperature is controlled at 80°C, and the gas-phase mixed product is condensed by the condenser at the top of the reactor, and then enters the primary ester-water separator, and the content of each component in the upper and lower layers is detected by gas chromatography. Open the water supply valve of the primary ester-water separator to replenish water for primary extraction, and use gas chromatography to detect the content of each component in the upper and lower layers. The conversion rate of chloroacetic acid was measured to be 80%, and the selectivity ...

Embodiment example 2

[0032] New method flow chart of the present invention sees figure 1 , Chloroacetic acid and methanol are stirred and mixed at room temperature in the raw material tank 1 according to the ratio of 1:2, and injected into the bottom of the fixed-bed reactor 3 through the raw material pump 2, and the catalyst is filled in the fixed-bed reactor, and the loading amount is about 2 / 3 of the container volume. The reaction temperature is controlled at 90°C, and the gas-phase mixed product is condensed by the condenser 4 at the top of the reactor, and then enters the primary ester-water separator 5, and the content of each component in the upper and lower layers is detected by gas chromatography. The conversion rate of chloroacetic acid was measured to be 90%, and the selectivity was 100%. Open the first-stage ester-water separator 5 water supply valve to replenish water for primary extraction, and use gas chromatography to detect the content of each component in the upper and lower lay...

Embodiment example 3

[0034] New method flow chart of the present invention sees figure 1 , chloroacetic acid and methanol are stirred and mixed at room temperature in the raw material tank 1 according to the ratio of 1:1.5, and then injected into the bottom of the fixed-bed reactor 3 through the raw material pump 2, and the catalyst is filled in the fixed-bed reactor. 2 / 3 of the container volume. The reaction temperature is controlled at 120°C, and the gas-phase mixed product is condensed by the condenser 4 at the top of the reactor, and then enters the primary ester-water separator 5, and the content of each component in the upper and lower layers is detected by gas chromatography. The conversion rate of chloroacetic acid was measured to be 98%, and the selectivity was 100%. Open the first-stage ester-water separator 5 water supply valve to replenish water for primary extraction, and use gas chromatography to detect the content of each component in the upper and lower layers. The lower layer en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com