Comprehensive processing method for ardealite washing technology

A comprehensive treatment and phosphogypsum technology, applied in the comprehensive treatment of phosphogypsum water washing technology, and the comprehensive treatment of phosphogypsum, can solve the problems of prolonging the setting time of hemihydrate gypsum, reducing the structure and quality of gypsum, reducing the strength, etc. Batch processing, favorable for promotion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

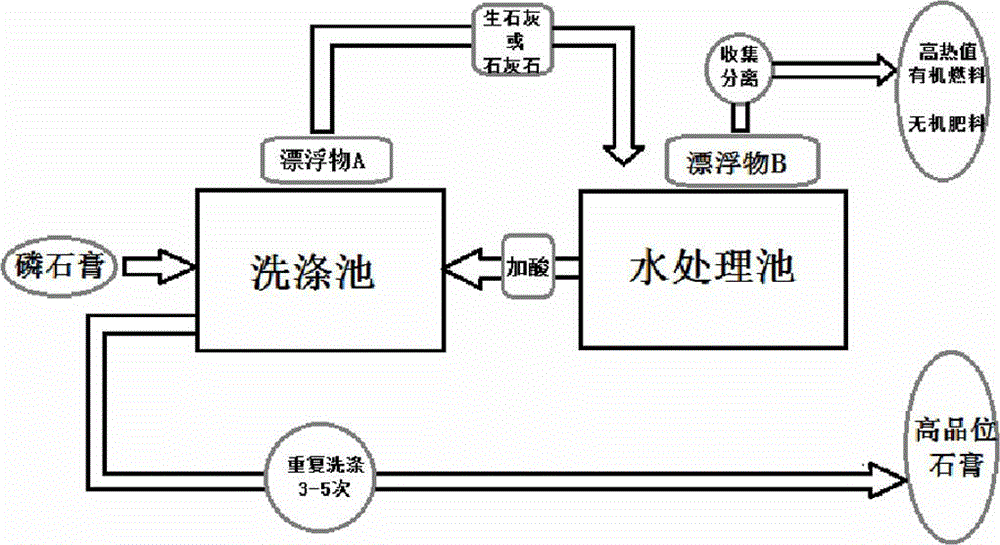

[0045] Attached below figure 1And embodiment the present invention is described in further detail. A composite washing method of the present invention that effectively utilizes organic impurities and soluble phosphorus and fluorine impurities in phosphogypsum, uses the organic floating matter obtained in the washing process to wash and filter calcium phosphate and calcium fluoride produced after alkali reaction in the filtered water It plays a flocculation function, makes the sediment float, removes phosphorus and fluorine substances in the washing water, and realizes the recycling of the washing water.

[0046] Specific steps:

[0047] (1) According to the mass ratio of gypsum and water as 1:3, weigh 100kg of phosphogypsum, add 300kg of water to soak and stir for 15min;

[0048] (2) After standing for 5 minutes, collect the floating organic matter A on the liquid surface, and collect the washing liquid (about 297kg);

[0049] (3) Add A to the washing solution, add 80g of q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com