Carbon monoxide shifting process

A carbon monoxide and process technology, applied in the field of conversion processes, can solve the problems of large system resistance, easy high temperature deactivation of catalysts, easy temperature flying of reactors, etc., and achieves low equipment investment and operating costs, simple and reliable temperature control, and broad market application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

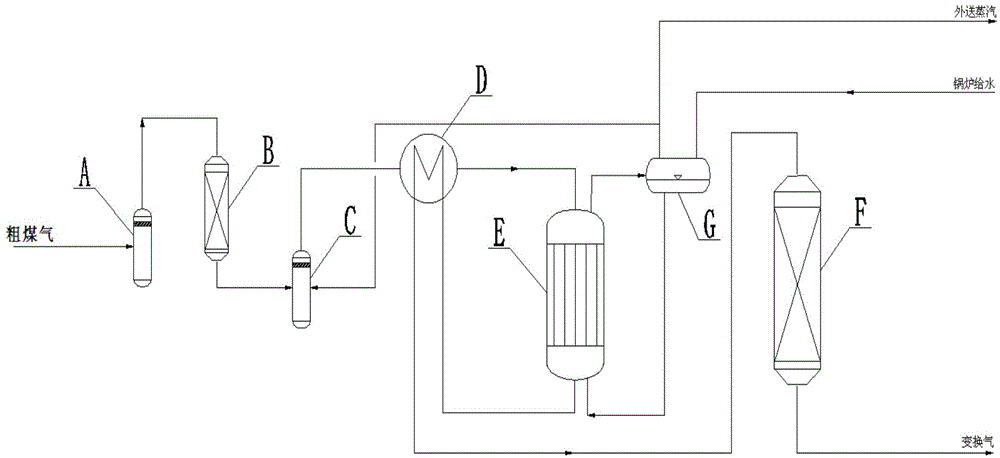

[0025] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0026] Gas separator A, gas filter B, steam mixer C and gas preheater D, the steam mixture is connected to the isothermal reactor E through the tube side or shell side of the gas preheater D, and the isothermal reactor E is then connected to the adiabatic reactor F through the shell side or tube side of the gas preheater D;

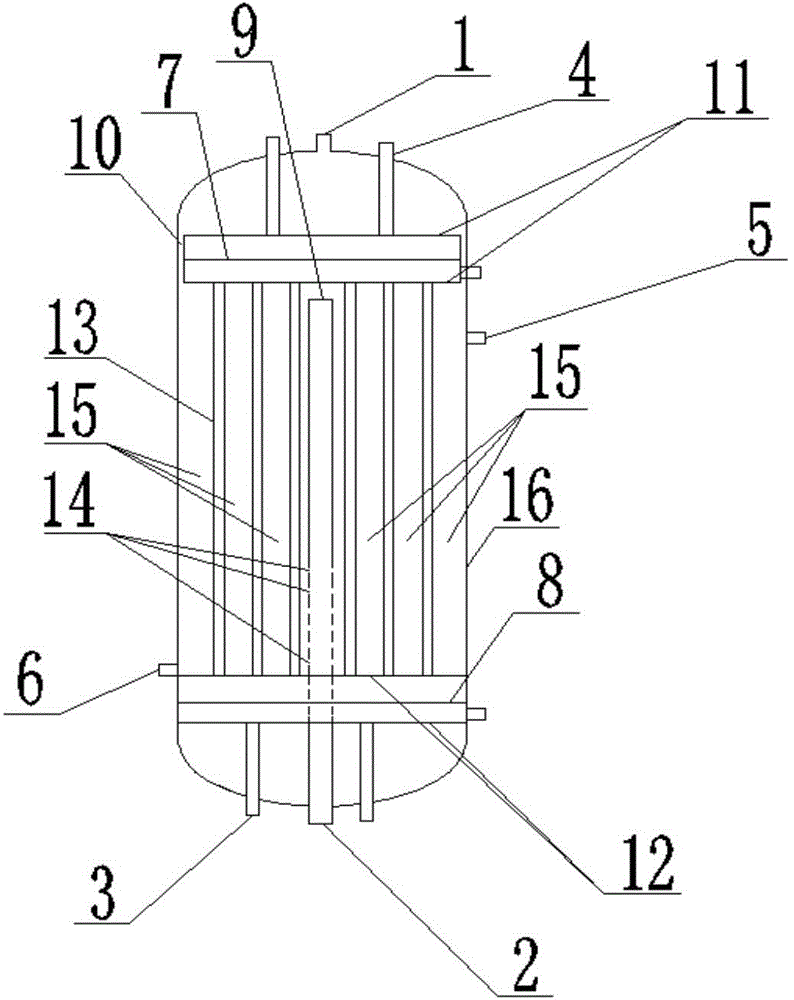

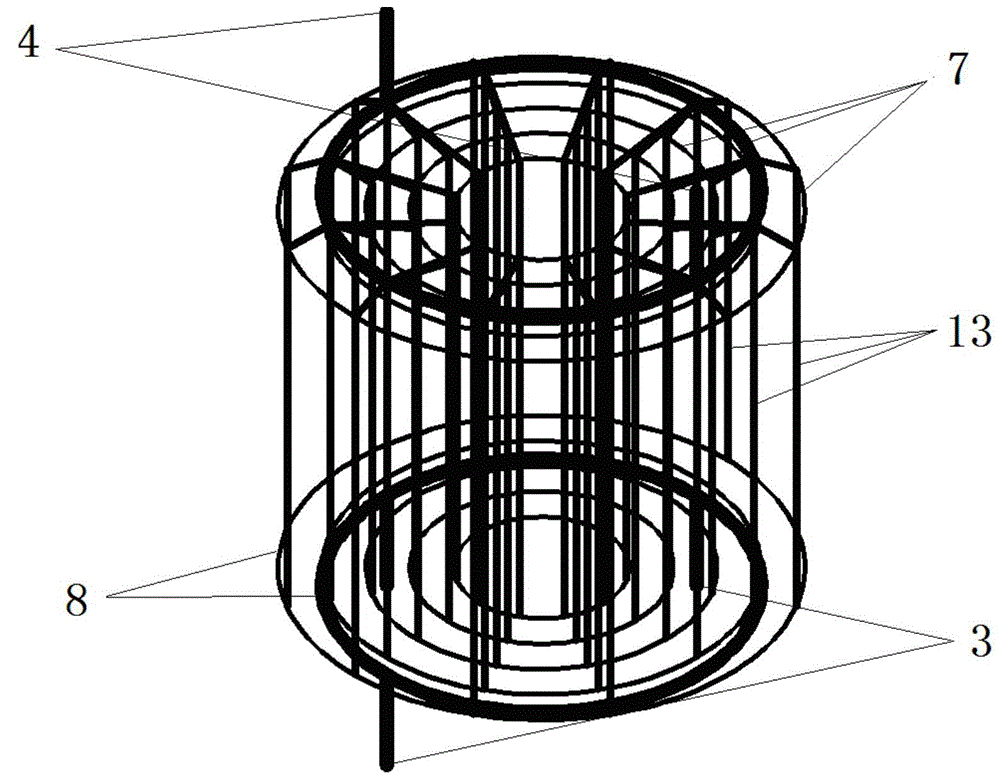

[0027] The structure of the isothermal reactor E is to include a housing 16, the upper section and the lower section of the housing 16 are respectively equipped with an upper chamber water distributor 7 installed in the upper chamber support plate 11 and a lower chamber water distributor installed in the lower chamber support plate 12. The water dispenser 8, the upper chamber support plate 11 has an annular gap 10 from the wall surface of the shell 16, and the upper chamber water distributor 7 and the lower chamber distributor 8 are connected through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com