Wide-width aluminum strip double-axis coiling and longitudinal splitting machine

A slitting machine and aluminum strip technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problem of high difficulty in slitting aluminum strips, and achieve the effect of wide processing range, high precision and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with drawings and embodiments.

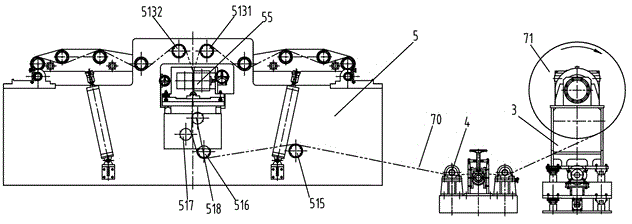

[0040] Such as figure 1 As shown, the present invention includes an uncoiler 3, an adjustment device 4, and a host 5, and the uncoiler 3, the adjustment device 4, and the host 5 are arranged in a plane and connected in sequence according to the above sequence;

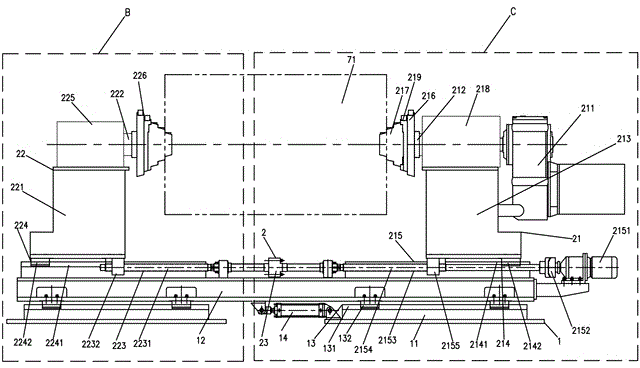

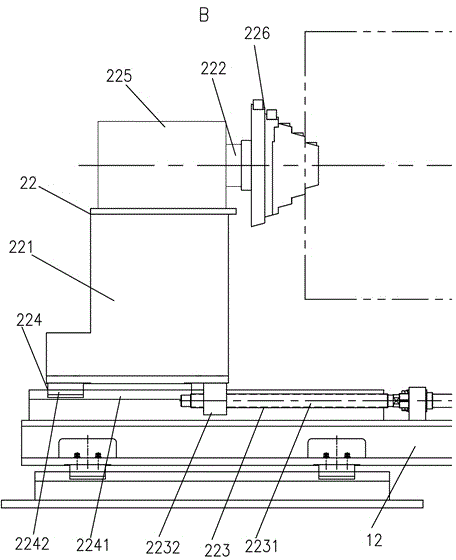

[0041] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the uncoiler 3 includes an uncoil base 1 and an uncoil driving device 2, and the uncoil drive device 2 is arranged on the top surface of the uncoil base 1; the uncoil base 1 includes two fixed bases 11, a movable base 12, and a pair of rolling linear guide rail pairs 13. The hydraulic cylinder 14 and the two fixed bases 11 are placed separately. Each rolling linear guide pair 13 includes a guide rail 131 and several sliders 132. The two guide rails 131 are fixedly arranged on the two fixed bases in parallel. On the top surface of 11, seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com