A film-pressing wheel and film-pressing equipment thereof

A lamination wheel and inner tube technology, applied in lamination, lamination devices, electrical components, etc., can solve the problems of rapid temperature fluctuation, large defect rate of board surface, and uneven heat conduction of metal, so as to achieve soft temperature change, Improve yield and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

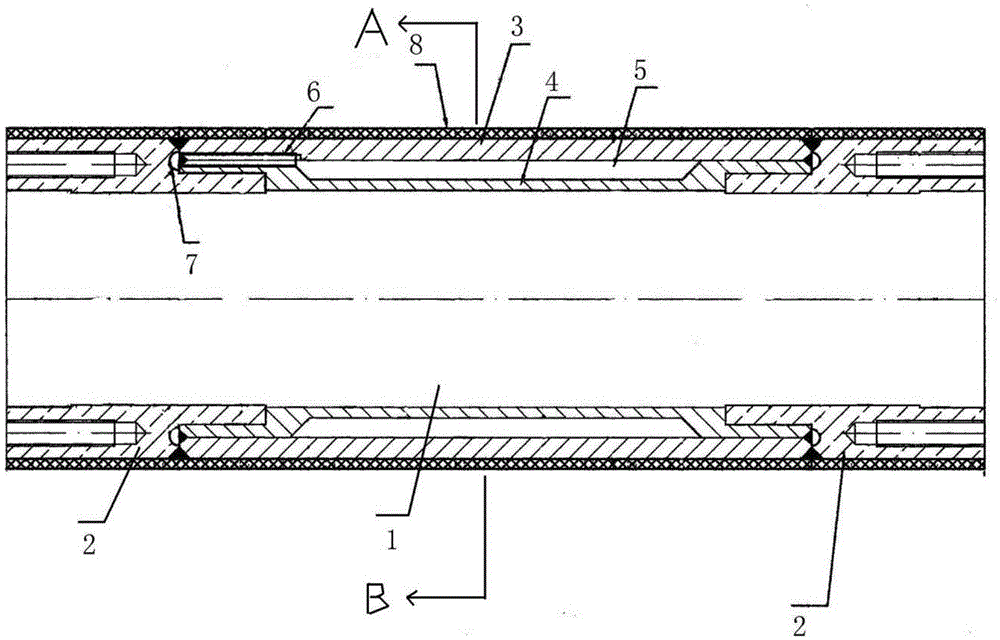

[0035] see figure 1 , a laminating wheel provided by an embodiment of the present invention includes a tube body 1 , a heat source arranged inside the tube body 1 and a rubber surface 8 covering the outside of the tube body 1 .

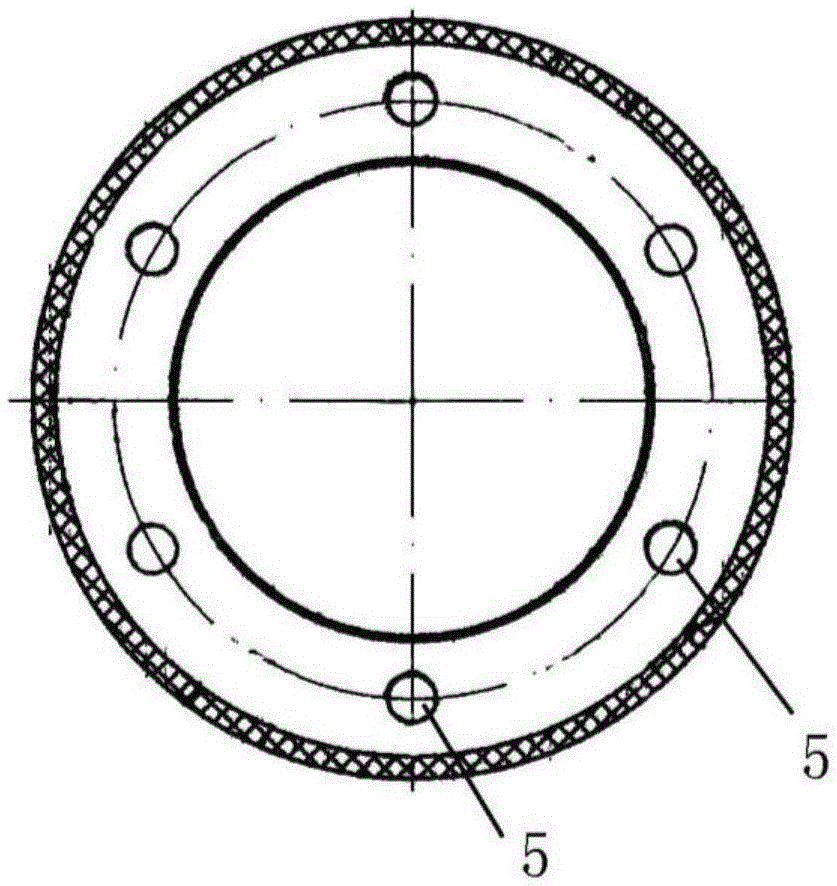

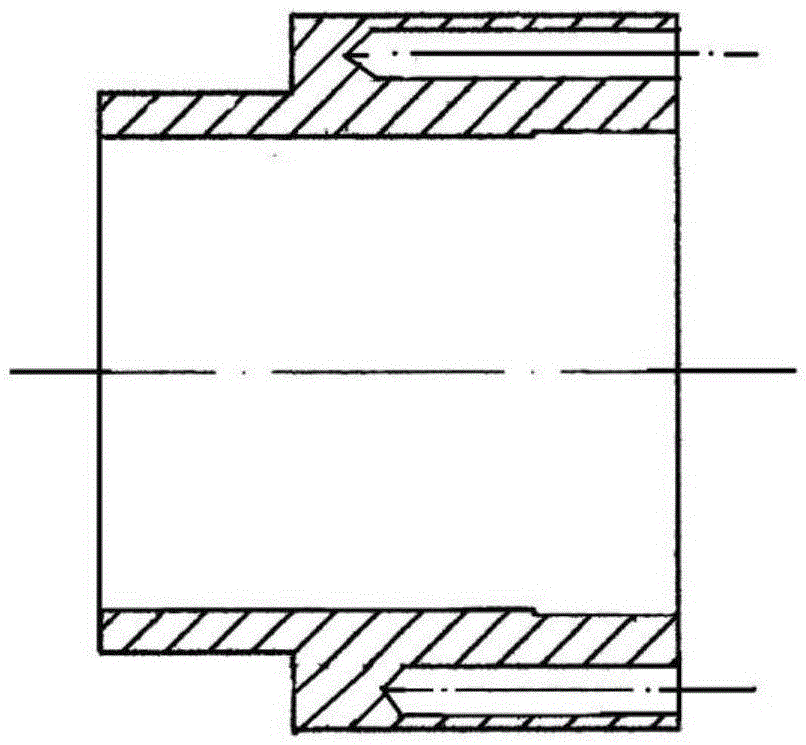

[0036] Specifically, the tube body 1 includes an outer tube 3, an inner tube 4 and a shaft head 2; on the outer wall of the inner tube 3, a plurality of oil storage grooves 5 extending in the axial direction are arranged, and the plurality of oil storage grooves 5 in the inner tube 4 Evenly distributed along the circumference in parallel on the outer wall, such as figure 2 shown. Each oil storage tank 5 is correspondingly provided with an oil filling tank 6 , the oil filling tank 6 is arranged on the outer wall of the inner tube 4 , one end of the oil filling tank 6 communicates with the oil storage tank 5 , and the other end extends to the end of the inner tube 4 . The inner tube 4 is nested and installed in the outer tube 3, and the outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com