A kind of fabric and its use

A fabric and inner layer technology, which is applied in the field of clothing fabrics, can solve problems such as difficult weaving, easy loosening of intermediate yarns, and uneven surface of fabrics, so as to reduce labor costs and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

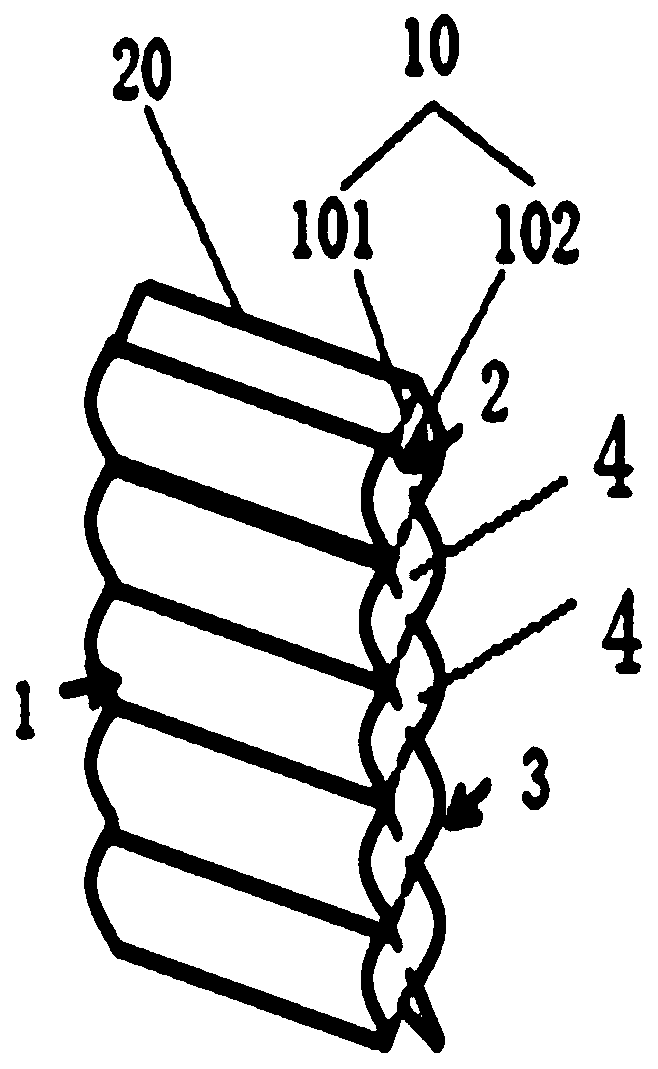

[0034] Embodiment 1 of the present invention provides a kind of fabric, such as figure 1 As shown, a fabric is formed by interweaving multiple warp yarns and multiple weft yarns, wherein the fabric includes: a surface layer 1 , an inner layer 3 , and an intermediate layer 2 arranged between the surface layer 1 and the inner layer 3 .

[0035] Each part of each warp yarn is a part of the surface layer 1, the middle layer 2, and the inner layer 3 respectively, and shuttles and circulates alternately along different positions among the surface layer 1, the middle layer 2, and the inner layer 3.

[0036]And, after each warp yarn 10 interweaves with the weft yarn 20 in the surface layer 1, the weft yarn 20 in the middle layer 2, and the weft yarn 20 in the inner layer 3, a connecting surface and a plurality of staggered distributions are formed between the surface layer 1 and the inner layer 3. A three-dimensional cavity 4 for filling down.

[0037] In summary, it can be seen that...

Embodiment 2

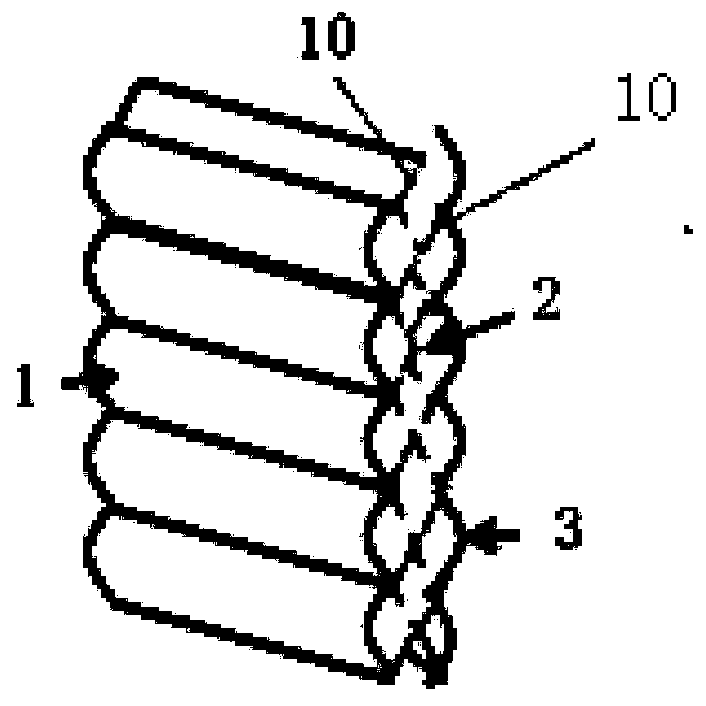

[0045] Embodiment 2 of the present invention provides a kind of fabric, and the yarn specification, structure, weaving process, processing technology of the fabric provided in Embodiment 2 of the present invention are roughly the same as Embodiment 1 of the present invention, and its difference is, In this embodiment 2, when the fabric is gray cloth, the warp and weft density of the surface layer 1 and inner layer 3 are warp density: 120 / inch, and weft density: 92 / inch. The middle layer is warp Density: 60 yarns / inch, weft yarn density: 46 yarns / inch, and after it is processed from gray cloth into finished products, the warp yarn densities of the surface layer 1 and inner layer 3 are both: 128 yarns / inch, and the weft yarn density is 106 yarns / inch with a coverage factor of 2026. The warp yarn density of the middle layer 2 is 64 yarns / inch, the weft yarn density is 53 yarns / inch, and the cover factor is 1013. And, according to the method that adopts in above-mentioned embod...

Embodiment 3

[0048] Embodiment 3 of the present invention provides a kind of fabric, and the yarn specification, structure, weaving process, processing technology of the fabric provided in Embodiment 3 of the present invention are substantially the same as Embodiment 2 of the present invention, and its difference is, When the fabric in this embodiment is a gray cloth, the warp density of the surface layer 1 and inner layer 3 is: 143 threads / inch, the weft thread density: 102 threads / inch, and the warp thread density of the middle layer 2 is: 71 threads / inch , the weft yarn density is: 50 yarns / inch, and after it is processed from gray cloth into finished products, the warp yarn densities of the surface layer 1 and inner layer 3 are both: 152 yarns / inch, weft yarn density: 118 yarns / inch, and the cover factor is 2338 , the warp yarn density of the middle layer 2 is: 76 yarns / inch, the weft yarn density is 58 yarns / inch, and the cover factor is 1160. And, the method that adopts in above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com