Method for rolling rods with 150 square blanks and 165 square blanks through both rough rolling and intermediate rolling

A technology for rough and medium rolling and rods, which is applied in the direction of metal rolling, guiding/positioning/alignment devices, etc., which can solve the problems of wasting manpower and financial resources, occupying a large inventory fund, and changing many racks, etc., so as to increase production capacity , Simplify operation and produce efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

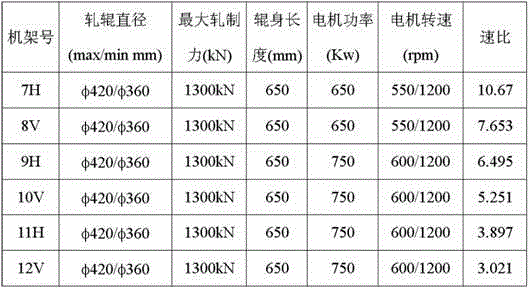

[0031] Kungang Honghe Steel Company is rolled with 3 550 rolling machines and 3 500 rolling machines. The mid-rolling machine is composed of 6 420 rolling machines. The hole systems are square-Yuan and Yuan-ellipse system.Series, a series of fine rolling each specification, rolled 165mm × 165mm and 150mm × 150mm blank rolled rolled rolling series. The original process plan has the following problems:

[0032] 1) There are many original craft holes and defense series.

[0033] 2) In order to meet the market demand, the rod line needs to change the variety frequently, change the variety of varieties, and waste a lot of time;

[0034] 3) There are many series, roll processing (large volume), defense assembly, process adjustment and other workloads, wasteing labor and financial costs;

[0035] 4) Frequent rollers, too many school samples are prone to slipping and other process accidents, causing waste products such as super -sizes;

[0036] 5) Due to the series of defense and material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com