A method for treating flue gas

A treatment method and flue gas technology, which is applied in the field of flue gas treatment and flue gas treatment generated by waste incinerators, can solve the problems of high flue gas content, low removal rate of heavy metals, low requirements for dust removal equipment, etc., and achieve high dust removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below with reference to the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

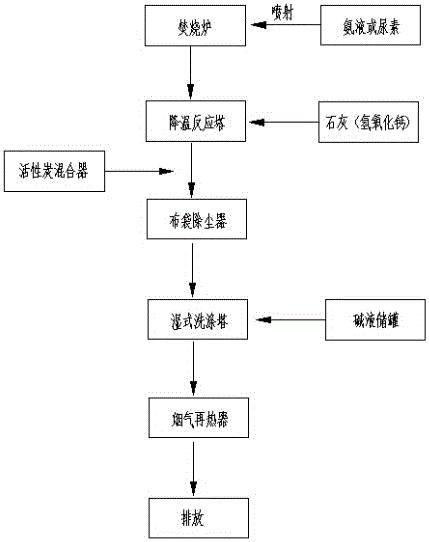

[0016] Such as figure 1 As shown, a flue gas treatment method, firstly, an injection device is installed in the incinerator, and the injection device injects a reducing agent into the incinerator. The reducing agent can be ammonia water or urea. Since the temperature in the incinerator is 850° ~1050℃, the oxygen concentration is 3%~5%, and the residence time of the flue gas in the incinerator is more than 2 seconds. Under this condition, the formation of dioxin can be effectively inhibited, and when ammonia or urea is sprayed, it will be mixed with the flue gas. The nitrogen oxides in the gas undergo a selective non-catalytic reaction, thereby reducing the concentration of nitrogen oxides in the flue gas. Then, the flue gas with reduced concentration of nitrogen oxides is passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com