Multi-purpose 10 kV drainage wire insulation fixer and work method with same

A drainage wire and fixer technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of complicated operation, single type of control wire, etc., and achieve the effect of wide application range, improved safety, and reliable locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Drainage line operation

[0050] 1) Safety fences are placed around the working point. Electricians No. 1 and No. 2 correctly wear a full set of qualified insulating clothes, insulating gloves, insulating helmets, insulating shoes, goggles, and wear safety belts respectively.

[0051] 2) Two operators climb the poles with insulated transmission ropes to the operating point, and keep a safe distance greater than 0.4 meters from the live body and the grounding body.

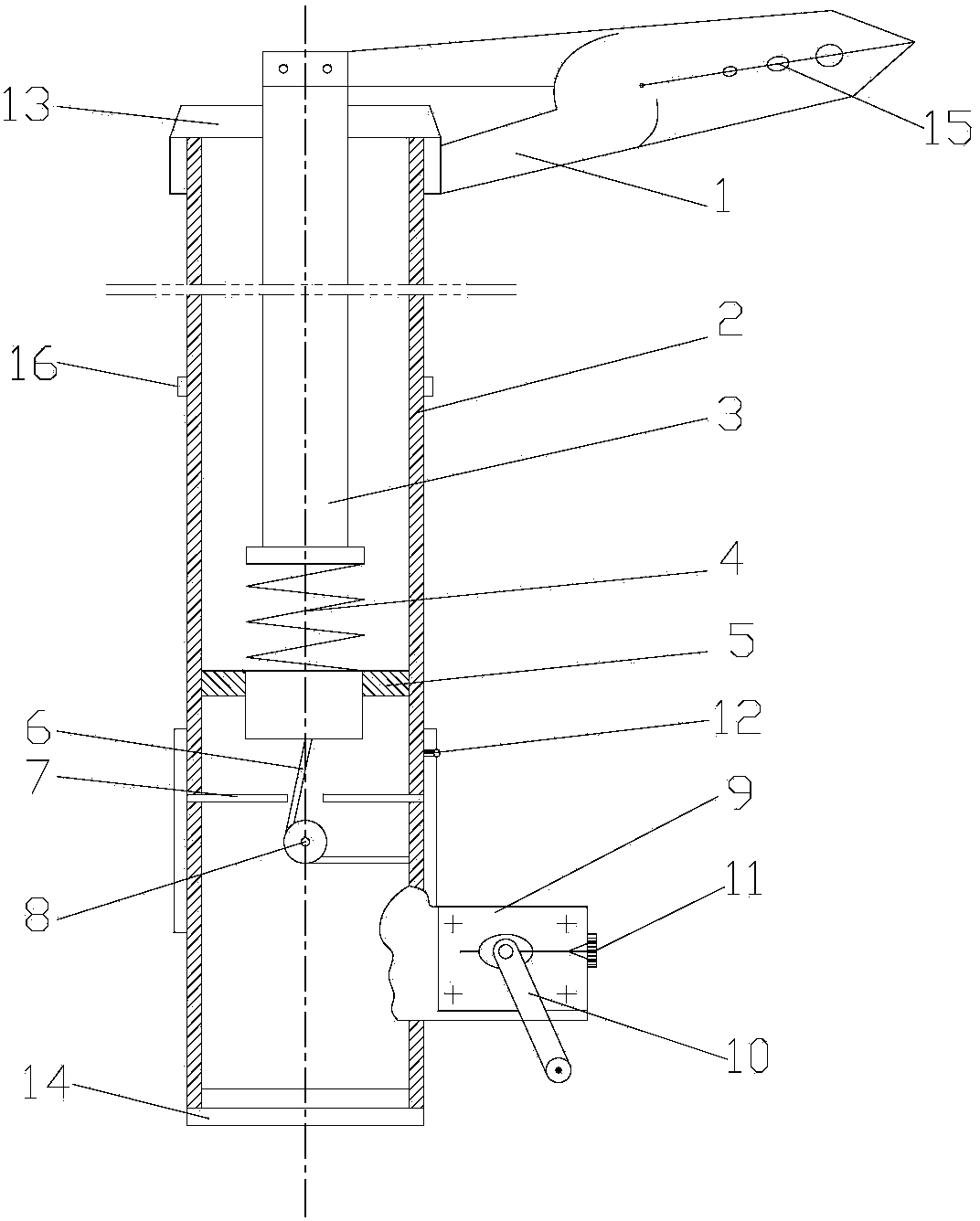

[0052] 3) The ground electrician passes the 10kV multi-purpose drain wire insulation holder and the insulated wire breaker to the pole electrician through the insulation rope.

[0053] 4) No. 1 electrician holds the 10kV multi-purpose drainage wire insulation holder at the position below the insulation length limit label, and puts the wire in the corresponding groove according to the wire type, opens the lock pin, shakes the insulation rocker, and waits for the clamp to close and fix it before breaking Lock the lock...

Embodiment 2

[0066] Insulated bucket car breaking drainage line operation

[0067] 1) Safety fences are placed around the working point. Electricians No. 1 and No. 2 correctly wear a full set of qualified insulating clothes, insulating gloves, insulating helmets, insulating shoes, goggles, and wear safety belts respectively.

[0068] 2) Two operators with 10kV multi-purpose drain wire insulation holders and insulated wire breakers, take the insulated bucket car to the vicinity of the operating point, shield the charged objects that may be touched, and maintain sufficient safety with the charged objects and grounding objects The distance is greater than 0.4 meters.

[0069] 3) The No. 1 electrician holds the 10kV multi-purpose drain wire insulation holder at the position below the insulation length limit label, and puts the wire in the corresponding groove according to the wire type, opens the lock pin, shakes the insulation rocker, and waits for the clamp to close and fix it before breaking Lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com