Ultra-thin combined transformer

A combined transformer, ultra-thin technology, applied in the field of transformers, can solve the problems of not conforming to the development trend of small volume and high power, incomplete coupling of primary and secondary windings, inability to use automatic winding, etc., to meet the requirements of light, thin and small design, improve Production efficiency and the effect of improving the utilization of magnetic cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

[0017] Please refer to figure 1 , figure 1 It is a schematic diagram of the assembly structure of the ultra-thin combined transformer of the present invention.

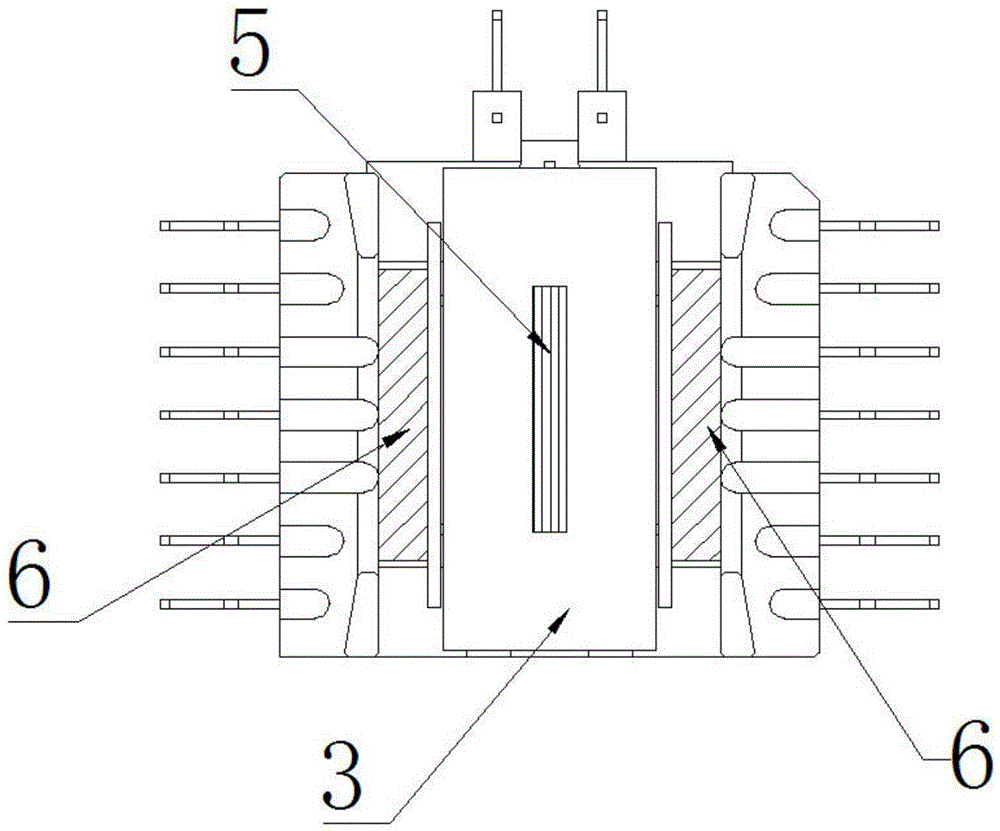

[0018] An ultra-thin combined transformer, comprising a winding frame 1 and a packaging frame, the winding frame 1 is arranged in the packaging frame, and the winding frame 1 has three parallel winding slots 4, in the middle A primary coil 5 is wound in the winding slot 4 , and a secondary coil 6 is wound in the winding slot 4 on both sides.

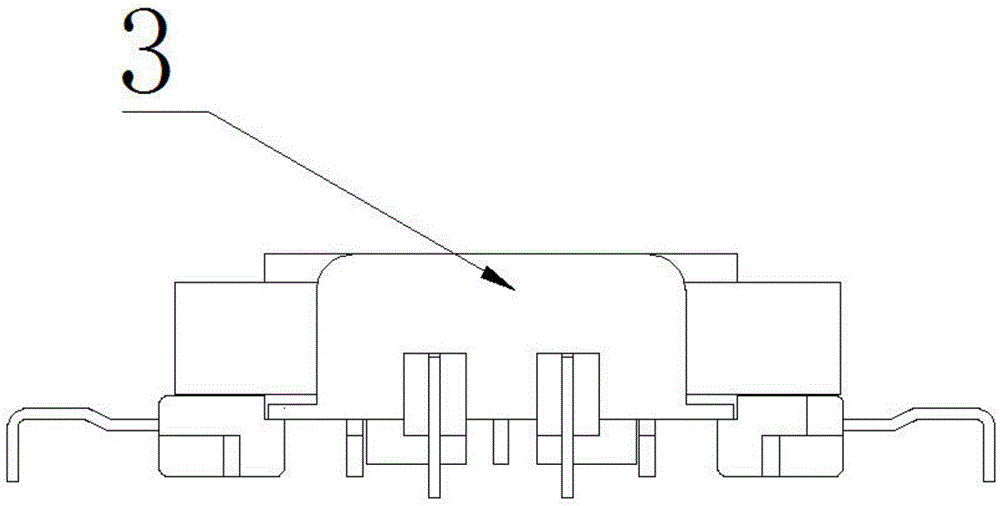

[0019] Such as figure 2 with image 3 as shown, figure 2 It is a schematic view of the structure of the ultra-thin combined transformer of the present invention, image 3 It is a schematic diagram of the side structure of the ultra-thin combined transformer of the present invention.

[0020] The lower surface of the winding frame 1 is provided with a wire-entry groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com