Device and method for testing bonding strength of front window glass of internal combustion locomotive cab

A test device and front window glass technology, which is applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve problems such as bonding strength tests of unbonded joints, and achieve the effect of verifying reliability and good practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

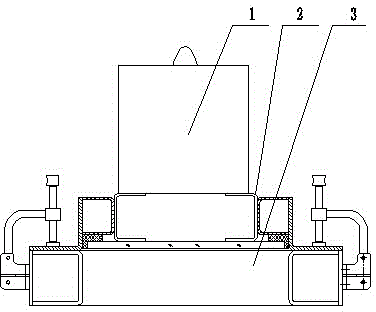

[0020] figure 1 It is a structural schematic diagram of the present invention, including a test device 3, a channel steel 2 and a weight 1 in the figure, the channel steel 2 is placed on the test device 3, and the weight 1 is placed on the channel steel 2.

[0021] The height of the channel steel 2 is higher than that of the test device 3 .

[0022] The test method includes static load test and impact load test:

[0023] The static load test:

[0024] The first step is to place the frame to be tested flat on the test device 3 with the reverse side up and fasten it.

[0025] In the second step, place the two channel steels 2 on the glass that is close to the bonding part and is higher than the upper plane of the frame.

[0026] The third step is to lightly place the weight 1 on the channel steel 2, and let it stand for a period of time. During this period, observe the change state of the pressed glass and the bonding part. After the load is removed, check whether the glass b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com