Cyanobacteria organic fertilizer and manufacturing method thereof

A production method and technology of organic fertilizer, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of difficult drying, increased cost, high water content of blue-green algae, etc., and achieve the effect of solving pollution problems, improving production efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

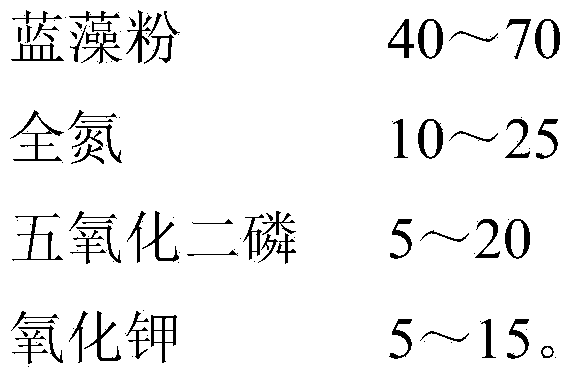

[0032] Technical scheme of the present invention: a kind of cyanobacteria organic fertilizer, comprises the raw material of following ratio by weight:

[0033]

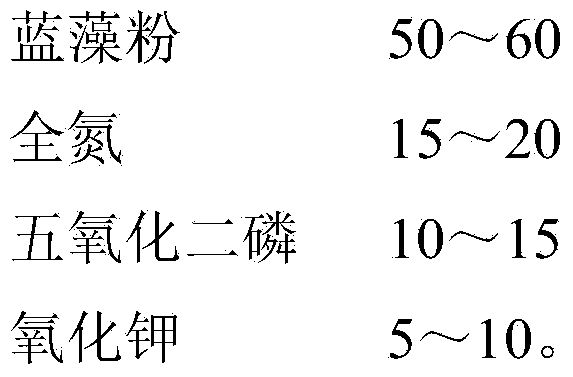

[0034] A kind of cyanobacteria organic fertilizer, comprises the raw material of following ratio by weight:

[0035]

[0036] The preparation method of described cyanobacteria organic fertilizer, comprises the following steps:

[0037] a. Collection: Collect the blooming cyanobacteria into algae-enriched water containing 8-10% of dry algae;

[0038] b. Concentration: the collected algae-enriched water is filtered and concentrated into algae pulp containing 50-60% of dry algae;

[0039] c. Dehydration: dehydrate the concentrated algae pulp to algae mud containing 65-75% of dry algae;

[0040] d. Drying: The dehydrated algae mud is dried through a drying tower to produce coarse algae powder with a dry algae content of more than 92%, and the drying temperature is controlled at 300-400°C;

[0041] e. Powder: the ...

Embodiment 2

[0044] A kind of cyanobacteria organic fertilizer, comprises the raw material of following ratio by weight:

[0045]

[0046] The preparation method of described cyanobacteria organic fertilizer, comprises the following steps:

[0047] a. Collection: Collect the blooming cyanobacteria into algae-enriched water containing 8-10% of dry algae;

[0048] b. Concentration: the collected algae-enriched water is filtered and concentrated into algae pulp containing 50-60% of dry algae;

[0049] c. Dehydration: dehydrate the concentrated algae pulp to algae mud containing 65-75% of dry algae;

[0050] d. Drying: The dehydrated algae mud is dried through a drying tower to produce coarse algae powder with a dry algae content of more than 92%, and the drying temperature is controlled at 300-400°C;

[0051] e. Powder: the obtained coarse algae powder is finely ground to 150-200 mesh to obtain fine algae powder;

[0052] f. Fertilizer preparation: Mix algae powder, total nitrogen, phos...

Embodiment 3

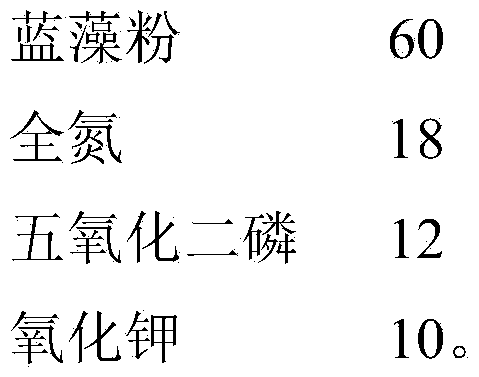

[0054] A kind of cyanobacteria organic fertilizer, comprises the raw material of following ratio by weight:

[0055]

[0056] The preparation method of described cyanobacteria organic fertilizer, comprises the following steps:

[0057] a. Collection: Collect the blooming cyanobacteria into algae-enriched water containing 8-10% of dry algae;

[0058] b. Concentration: the collected algae-enriched water is filtered and concentrated into algae pulp containing 50-60% of dry algae;

[0059] c. Dehydration: dehydrate the concentrated algae pulp to algae mud containing 65-75% of dry algae;

[0060] d. Drying: The dehydrated algae mud is dried through a drying tower to produce coarse algae powder with a dry algae content of more than 92%, and the drying temperature is controlled at 300-400°C;

[0061] e. Powder: the obtained coarse algae powder is finely ground to 150-200 mesh to obtain fine algae powder;

[0062] f. Fertilizer preparation: Mix algae powder, total nitrogen, phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com