A kind of sandwich structure composite material forming method

A composite material and molding method technology, which is applied in the field of composite materials to achieve the effects of high degassing efficiency, low consumption of consumables and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

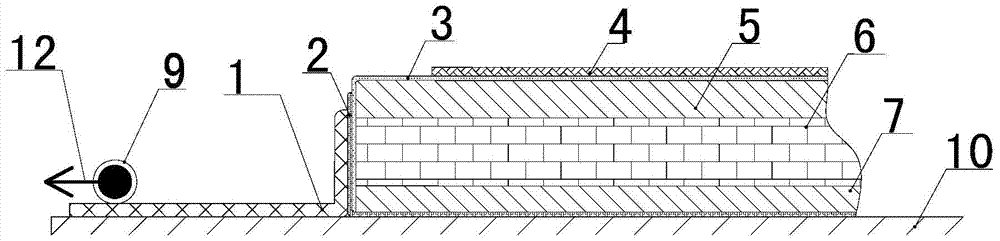

[0022] The molding process involved in the invention is described in detail by taking a composite plate with a sandwich structure with a panel thickness of 5 mm, a ceramic sandwich layer thickness of 15 mm, a back plate thickness of 20 mm, and an in-plane effective size of 980 mm×580 mm as an example.

[0023] The glass fiber fabric EWR600 plain weave fabric of 1000mm×600mm is used as the back plate blank 5 and the panel blank 7, and the single layer density of the glass fiber fabric is 600g / m 2 , 12 layers of panel blanks are aligned and stacked, and 46 layers of back panel blanks are aligned and stacked. A layer of closely packed hexagonal alumina ceramics with a side length of 11 mm and a thickness of 15 mm is used as the sandwich layer 6 .

[0024] One layer of 20-mesh polyethylene braided mesh with a monofilament diameter of 0.4mm and a size of 930mm×560mm is used as the diversion medium 4; the semi-permeable membrane 2 has an area density of 105g / m 2 The epoxy type Dahlt...

Embodiment 2

[0033] The molding process involved in the invention is described in detail by taking a foam sandwich composite plate with a panel thickness of 15 mm, a foam sandwich layer thickness of 20 mm, a back plate thickness of 30 mm, and an in-plane effective size of 980 mm×680 mm as an example.

[0034] Use 1000mm×720mm glass fiber fabric EWR600 plain weave fiber fabric as back plate blank 5 and panel blank 7, and the density of a single layer of glass fiber fabric is 600g / m 2 , 69 layers of back sheet blanks are neatly stacked, and 35 layers of panel blanks are neatly stacked, and a 1000mm×720mm×20mm polyurethane foam flat plate with through holes is used as the sandwich layer 6 .

[0035] Two layers of 20-mesh polyethylene woven mesh with a monofilament diameter of 0.4mm and sizes of 950mm×700mm and 950mm×680mm are used as the diversion medium 4, and the semi-permeable membrane 2 has a surface density of 105g / m 2 Epoxy Dahltexx, the maximum outer dimension is 1040mm×800mm, the size...

Embodiment 3

[0044] Taking a balsa sandwich composite plate with a panel thickness of 6mm, a balsa sandwich layer thickness of 20mm, a backboard thickness of 10mm, and an in-plane effective size of 1450mm×700mm as an example, the molding process involved in the invention is described in detail.

[0045] The plain weave carbon fiber fabric of 1500mm×720mm is used as the back plate blank 5 and the panel blank 7, and the single layer density of the carbon fiber fabric is 400g / m 2 , 35 layers of back panel blanks are neatly stacked, and 21 layers of panel blanks are neatly stacked, and the double layers of rectangular Balsa balsa wood blocks of 40mm×20mm×10mm are neatly and closely arranged as the sandwich layer 6 .

[0046] One layer of 20-mesh polyethylene woven mesh with a monofilament diameter of 0.4mm and a size of 1450mm×700mm is used as the diversion medium 4; the semi-permeable membrane 2 has an area density of 105g / m 2 Epoxy Dahltexx, the maximum outer dimension is 1550mm×780mm, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com