Automobile connector with reinforced elastic terminal structure

An automotive connector and bullet technology, which is applied to connection, contact parts, and two-part connection devices, etc., can solve the problems of poor elastic structure reset performance, inconvenient terminal extraction, insufficient terminal retention, etc., so as to improve reliability. , reduce processing costs, solve the effect of insufficient elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

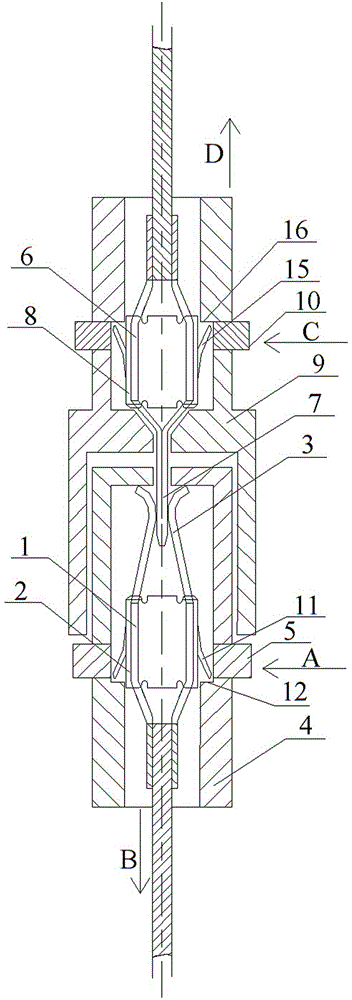

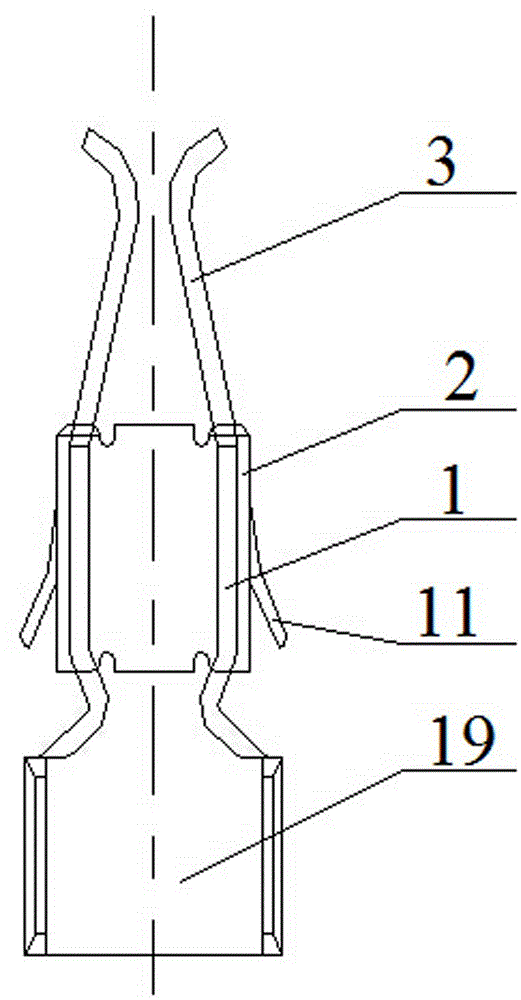

[0024] like figure 1 , figure 2 and image 3 As shown, the automotive connector with reinforced terminal elastic structure in this embodiment includes a socket terminal, a plug terminal, a socket terminal sheath and a plug terminal sheath, and the socket terminal includes a socket terminal main body formed by stamping a metal plate. The main body of the socket terminal includes a box body I1, and the box body I includes a bottom wall and two side walls, and a clamping shrapnel 3 extends upward from the two side walls of the box body I; There is a box part II2 formed by punching a metal plate, and a first elastic part extends downward from the two side walls of the box part II, and the first elastic part is a socket terminal back-stop shrapnel 11 made of stainless steel. The socket terminal is located in the socket terminal sheath 4, and the inner wall of the socket terminal sheath is provided with a boss 12 that matches the socket terminal stop spring; when the socket termi...

Embodiment 2

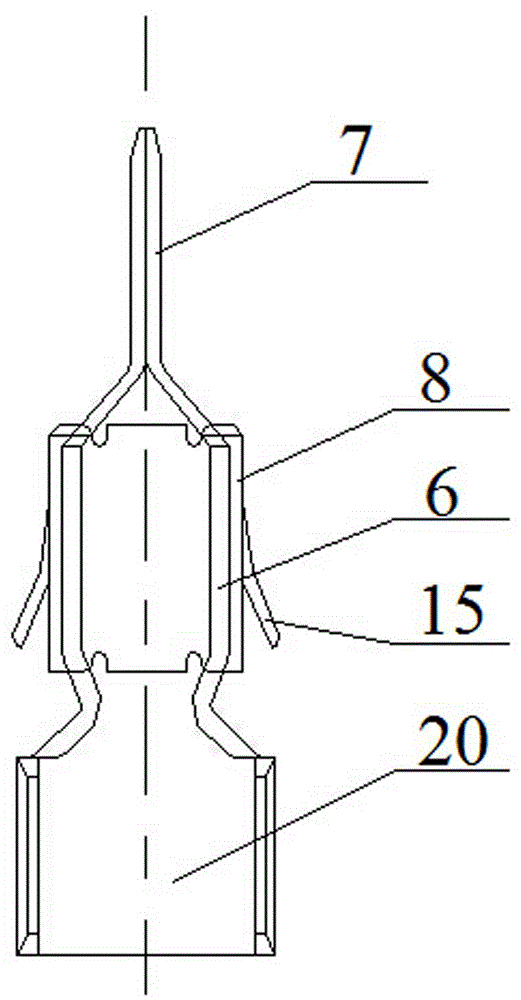

[0028] like Figure 4 , Figure 5 and Image 6As shown, the automotive connector with reinforced terminal elastic structure in this embodiment includes a socket terminal, a plug terminal, a socket terminal sheath and a plug terminal sheath, and the socket terminal includes a socket terminal main body formed by stamping a metal plate. The main body of the socket terminal includes a box body I1, and the box body I includes a bottom wall and two side walls, and a clamping shrapnel 3 extends upward from the two side walls of the box body I; There is a box part II2 formed by punching a metal plate, and a first elastic part extends downward from both side walls of the box part II. The first elastic part is a first tenon 13 made of stainless steel. The socket terminal Located in the socket terminal sheath 4, a first tenon 14 matching the first tenon is provided on the inner wall of the socket terminal sheath; when the socket terminal is assembled with the socket terminal sheath, th...

Embodiment 3

[0032] In the automobile connector with strengthened terminal elastic structure in this embodiment, the first elastic part is a socket terminal stop-back shrapnel made of stainless steel. The boss that matches the terminal anti-return shrapnel; the socket terminal anti-retraction shrapnel is deformed when the socket terminal is assembled with the socket terminal sheath, and the socket terminal anti-retraction shrapnel is reset after the assembly is completed. Positioning, a socket terminal pressing part is provided on the socket terminal sheath corresponding to the socket terminal stop spring. When the socket terminal needs to be pulled out for maintenance, press the socket terminal pressing part to make the socket terminal stop spring Elastic deformation occurs so that the socket terminal is removed from the socket terminal sheath;

[0033] The second elastic part is a second tenon made of stainless steel; the plug terminal is located in the plug terminal sheath, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com